CAD and CAM are paving the way for faster and error-free auto manufacturing

By OEM Update Editorial December 29, 2023 6:45 pm IST

Shatyabrata Das, Senior General Manager at IAC-International Automotive India Pvt. Ltd, highlights using 3D printing, injection moulding, CAD, and CAM technologies in streamlining manufacturing processes. He emphasises how these technologies have significantly minimised production time and eliminated errors in the work.

How is 3D printing leveraging the manufacturing sector in India?

3D printing, also known as additive manufacturing, represents a significant departure from traditional subtractive manufacturing methods. In the subtractive approach, you start with a solid block and remove the material until you achieve the desired part. 3D printing, on the other hand, works in reverse: you build the part layer by layer, depositing the materials, be it resin, metal, or inserts, as needed. This method is considered a cleaner process.

Cooling plays a significant role in mould manufacturing this helps both core and cavity half to maintain optimal temperature. Traditionally, creating cooling channels in moulds involved drilling holes, connecting them and inserting baffles which are time consuming and chances of error in manufacturing are high. However, 3D printing offers greater flexibility. With 3D printing, you can design and print cooling channels precisely to your specifications, greatly improving cooling efficiency. This results in faster cooling of moulded parts and, ultimately, shorter cycle times.

One noteworthy innovation in injection moulding is “conformal cooling,” which relies on 3D printing technology. Conformal cooling has brought significant improvements to mould performance. It helps reduce defects, enhances surface finish, and improves cooling efficiency. The potential of 3D printing in this context is vast, and it is considered the industry’s future. Some even speculate about the possibility of printing entire cars. This field is still evolving and holds great promise.

How is 3D printing used for designing complex components in automotive manufacturing?

3D design is a well-established concept that has been used for a while. However, recent advancements have brought about a significant transformation in how we utilize it. One such innovation involves white light scanning for reverse engineering components, greatly simplifying the process. In the past, the conventional approach required modelling in various CAD software applications.

Our current workflow incorporates cutting-edge 3D scanning technology. We begin by capturing a comprehensive scan of the object or path, generating a data cloud. Subsequently, this data is utilized to reconstruct a CAD model, thereby completing the process.

How are testing and validation techniques applied for designs and achieving accuracy of the automotive components?

Testing and validation play a significant role. It spans from the individual component level to the larger scale, such as in the case of a vehicle like a car. The validation process is extensive and multi-faceted. We initiate a CAE (Computer-Aided Engineering) analysis for every component we work with within our software. Additionally, at our design centre we strive to replicate and verify the accuracy of these analyses in a laboratory setting.

Our testing procedures encompass a wide range of scenarios, including real-time simulations. For instance, comprehensive crash tests for vehicles and safety tests for individual car parts are performed to ensure the safety of passengers. This validation process begins at the component level, extends to assembly, and ultimately culminates in testing under actual vehicle conditions.

What are the latest trends in the die and mould industry?

The die and mould industry is experiencing rapid growth as per the data its expected to grow by INR 26K cr by FY 25-26. Before the COVID-19 pandemic, we heavily relied on sources outside India, mainly China and Korea. For an example, we are making approximately 400-450 moulds and this will make components ranging from instrument panels, doors and consoles modules . Over the past two years, we have yet to outsource tooling work beyond India. This demonstrates the significant progress of the Indian industry. India now boasts many tool makers capable of producing world-class tools, and we are successfully competing globally.

How are robots being utilized for mass production and improving accuracy?

Robots play a remarkable role, particularly when integrated with dies and moulds, to produce plastic components. In the past, we operated machines with human operators collecting the parts. Each machine required an operator for handling. However, now we have implemented a robust robotic system that connects to all machines, enabling the robots to handle the parts. This means machines run continuously without interruptions, leading to increased productivity. Furthermore, relying on robots for handling eliminates the issues associated with multiple human handling, which can result in problems related to transit. Robots efficiently transport the moulded parts to the final assembly line, becoming indispensable in moulding.

What new advancements have taken place in CAD/CAM software tools?

CAM software has seen significant advancements in recent times. In the past, designing tools for die and mould production was a time-consuming endeavor. However, the process has evolved considerably with the introduction of patched programs and continuous software development. These software enhancements have absorbed a wealth of knowledge and learning, streamlining mould design significantly. What used to take 10-20 days can now be accomplished within a week.

The beauty of CAM lies in its ability to accelerate production. It closely monitors the cutting tool’s performance, ensuring precise control and efficient tool movement. This optimization has led to a reduction in manufacturing processes, creating a seamless and continuous workflow. Each year brings new additions to the core software, continually enhancing the efficiency of mould manufacturing. Consequently, the cycle from CAD design to the actual production of parts on the factory floor has shortened, while the overall accuracy has notably improved.

How are all these technologies deployed for the advancement of the automotive industry?

The automotive industry has become inseparable from software, and it plays a pivotal role from conception to production. It begins with receiving crucial data from OEM customers, forming the foundation for creating models. CAD software is essential for this process. The transition to CAM is crucial for the subsequent manufacturing phase.

In the past, the manufacturing of a car was a lengthy process. From experience derived while working for OEM, it can be attested that it used to take about four years from initial design to a vehicle hitting the road (Design Board to Road). However, the landscape has transformed. The process has been shortened to just 16-18 Months . Remarkably, industry leaders like Tesla and other major Car manufacturers in India aim to roll out new car models in as little as 16 months. This remarkable acceleration underscores the profound impact of software in streamlining and expediting automotive development and production.

How are CAD and CAM technology shaping the industries’ future of die and mould manufacturing?

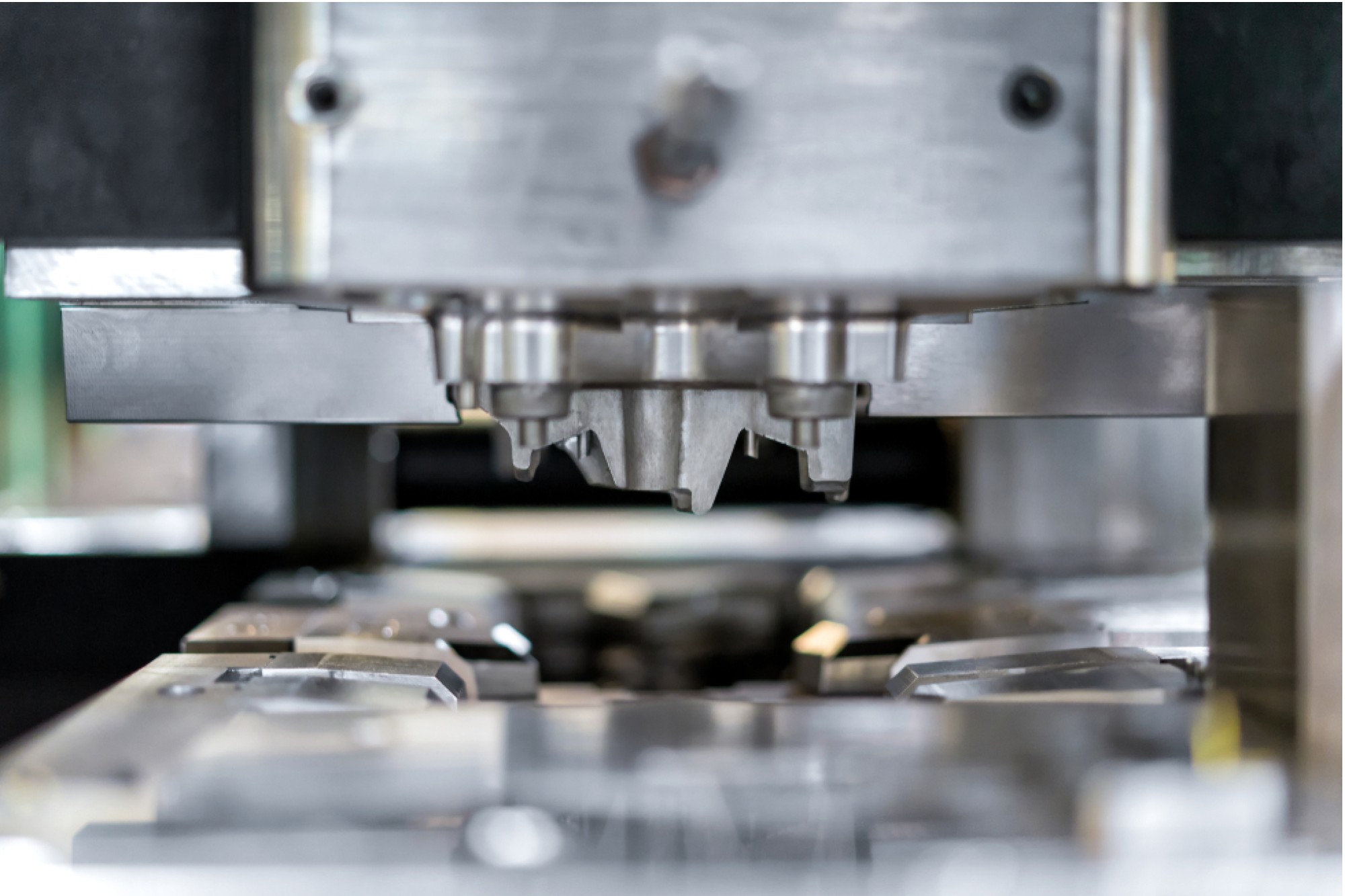

CAD and CAM are the fundamental building blocks of die and mould technology. It begins with creating an engineering CAD model as the foundation. From there, we proceed to mould design, a critical step in the process. In mould design, the primary input is the model itself. A typical mould comprises around 30-35 essential components, with the core and cavities being the primary elements responsible for shaping the final product. We rely on machines like CNC or VMC to bring these designs to life. Advanced 5X machines have emerged and plays a vital role in die manufacturing, but they require they need advance and modular CAM to support.

CAM bridges the gap between CAD and the machine. It involves translating the CAD model into machine-readable codes, such as G and M codes. These codes are what the computer-controlled machinery understands. Thus, converting CAD to CAM is crucial, enabling the machine to commence the tool-cutting process. In today’s industry, this CAD-to-CAM workflow is indispensable. It is an integral part of how things are manufactured.

Please state the role of injection moulding in the automotive industry.

Injection moulding is vital for moulding various plastic components for vehicles. Injection moulding machines are mainly of two types: vertical and horizontal. These machines are essential in the automotive industry as they produce most plastic parts inside a car. The process involves a sequence of steps, starting with CAD modelling, followed by CAM programming, the creation of injection moulds, injection moulding, inspection, value addition, and finally, integration into the vehicle.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.