Smooth surface finish with higher feed rate and low cutting resistance

By Staff Report September 17, 2024 4:59 pm IST

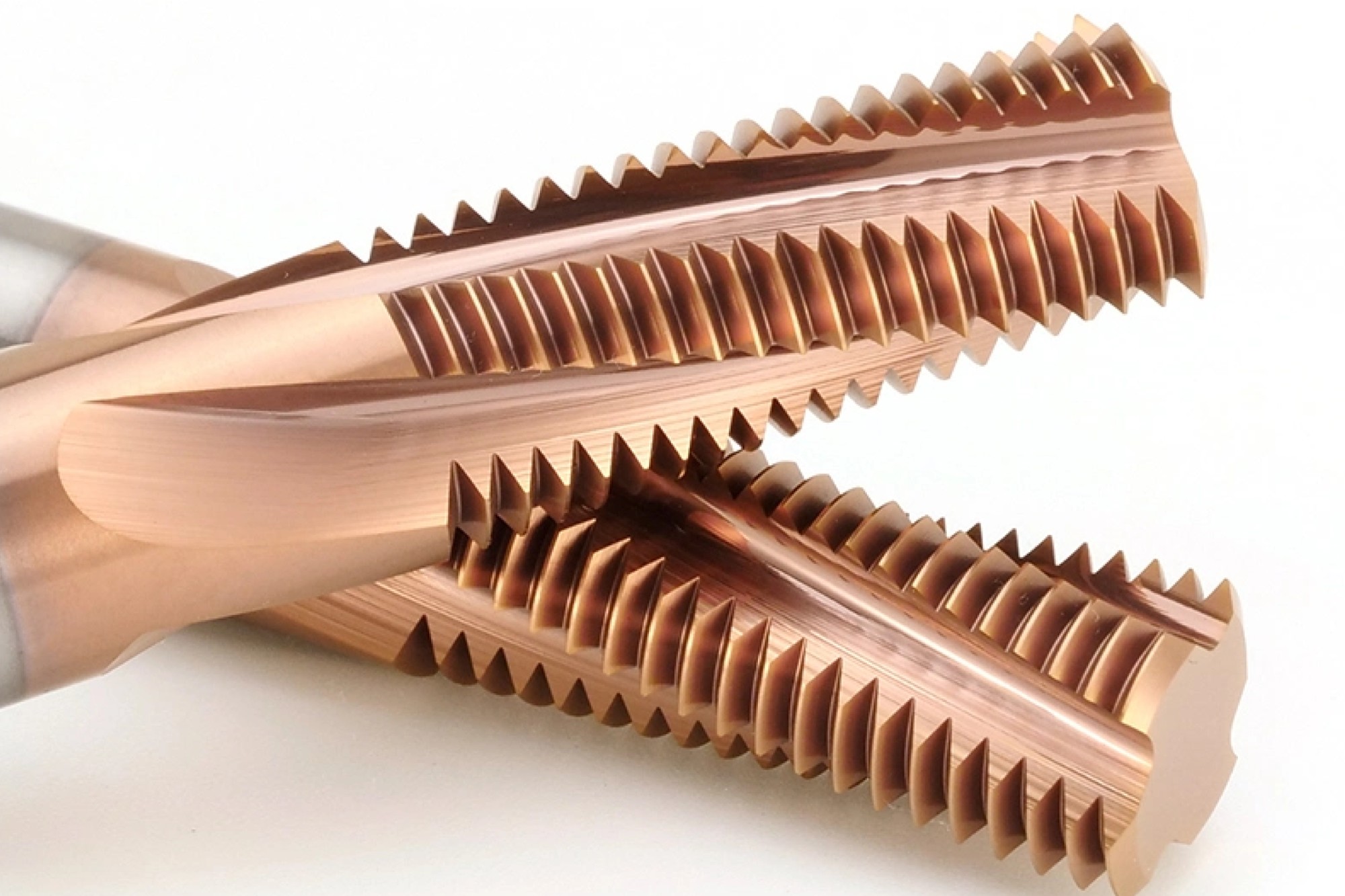

Face Mill Cutters are used for a variety of operations for facing styles, cutting angles and shapes. Now get the power of 2 Face Mill Cutter which can suit both 8-Edge & 16-Edge Milling Insert.

Dual Purpose Body

Two double-sided inserts can be used with a single body depending on the milling application to help reduce tool costs. They are stronger than the single-sided cutters. TruCut Face Mill Cutter can suit 8-Edge SNMU and 16-Edge ONMU Milling Insert.

SNMU Inserts are economical with their double-sided design, offering 8 cutting edges. Upto 6mm maximum depth of cut can be achieved using SNMU. ONMU Inserts offers 16 corners for improved economy and we can get 3mm maximum depth of cut.

ONMU & SNMU inserts can be used interchangeably on the same body. Using these inserts the cutter will have different cutter diameter and body height.

Features

TruCut Face Mill Cutters utilises double-sided inserts for excellent economy. This is a general-purpose cutter featuring high cutting-edge strength for high-efficiency milling and a low-burr chip breaker design that provides a high-quality machined surface. The fine-pitch design allows high-feed milling.

Improved runout precision and unique wiper edge shape ensure excellent surface finish quality of cutters. The additional edge chamfer reduces burrs and edge chipping of cutters. A high rake chip breaker is designed to reduce cutting force.

Same cutting performance as single-sided inserts plus superior economy. Achieves levels of cutting-edge sharpness and machined surface quality equivalent to single-sided cutters at a maximum depth of cut as 3mm.

Benefits:Face Mill Cutter provides an excellent surface finish for smooth and precise surfaces. It is suitable for squaring up workpieces and achieving perpendicularity. It is versatile and capable of machining various materials, including ferrous and non-ferrous metals. A high material removal rate leads to increased efficiency.

The cutter provides good depth of cut capacity, relatively even cutting forces and a chip thinning effect that allows for high feed rates. The axial allowance of the design allows the insert to have a generous parallel land, which generates good surface finishes.

Application:

A Face Mill Cutter is used for cutting a flat surface perpendicular to the axes of the milling cutter. This process removes the material by rotating the facing tool counterclockwise as the table feeds the workpiece across the cutter.

The Indexable Face Mill Cutter has replaceable carbide inserts fixed to the face mill body. These inserts have cutting edges on multiple sides, allowing for multiple cuts before replacement. Indexable face mills are versatile and cost-effective because the inserts only need to be replaced when worn or damaged.

TruCut Face Mil Cutters are designed for high-speed machining with extremely high material removal rates. They feature a unique cutting-edge geometry that enables high feed rates and shallow depths of cut, minimising cutting forces and optimising chip evacuation. High-feed face milling cutters are often used for roughing operations and can significantly reduce machining time.

Indexable Face Mill Cutter with Carbide Inserts are suitable for machining various materials, including steels (carbon steels, alloy steels), stainless steels, cast iron, aluminium and nonferrous materials. The specific insert grade and geometry can be selected based on the material being machined.

Web: www.trucut-tool.com

Email: sales@trucut-tool.com

Contact: +91 – 7397771855 | +91 – 7397723118

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.