Reinforced cutting-edge geometry for smooth cutting

By Staff Report February 11, 2025 6:26 pm IST

TruCut Micro Boring Tools are designed to work in small bores. These tools are for the high-tech, medical, and small components industries. They can be used in machining centres or with conventional machines.

Feature

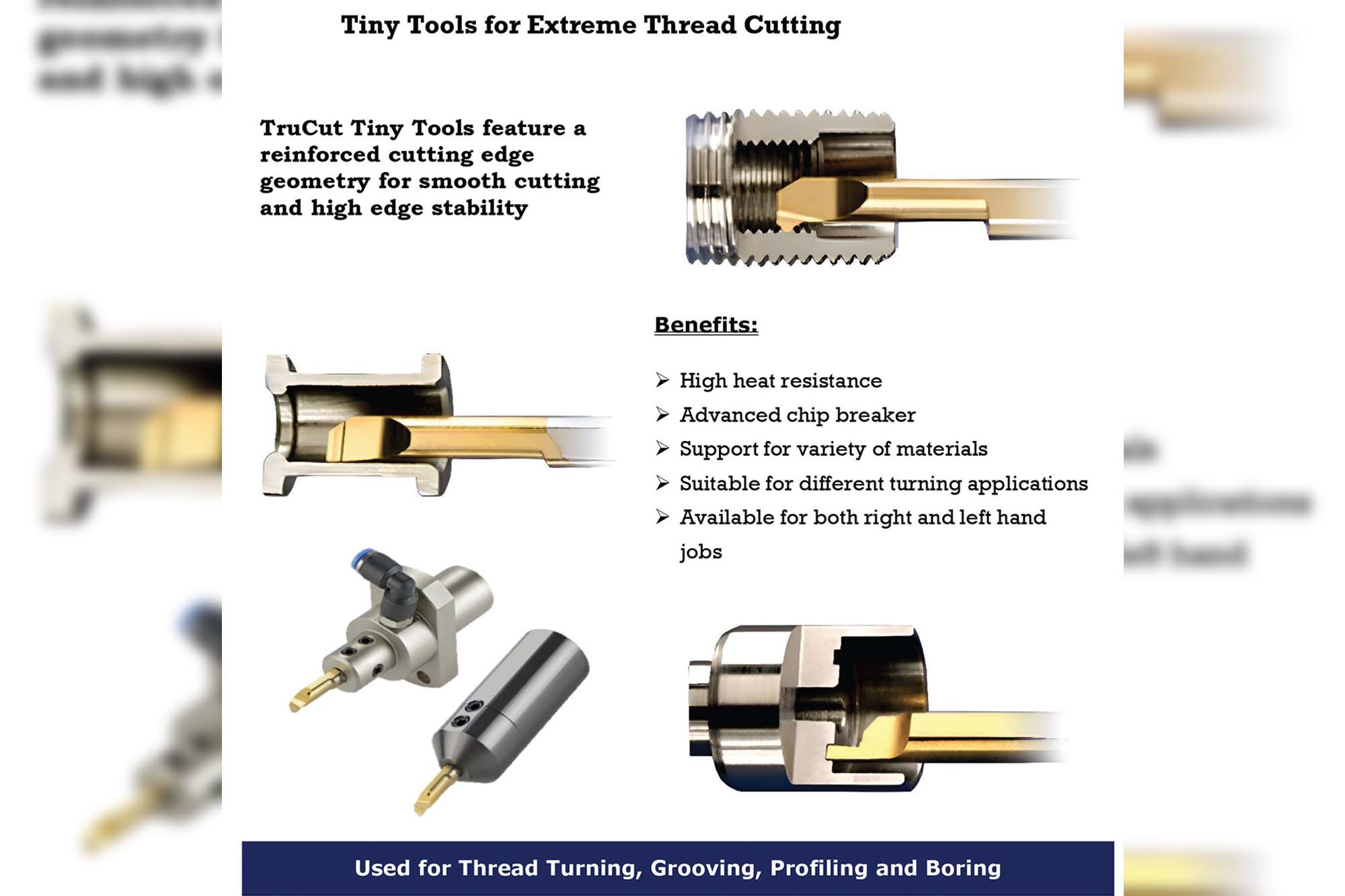

TruCut Tiny Tools feature a reinforced cutting-edge geometry for smooth cutting and high-edge stability. These tools support diameters as small as 1.0 mm for certain tools and are suitable for most turning applications such as thread turning, grooving, profiling, and boring.

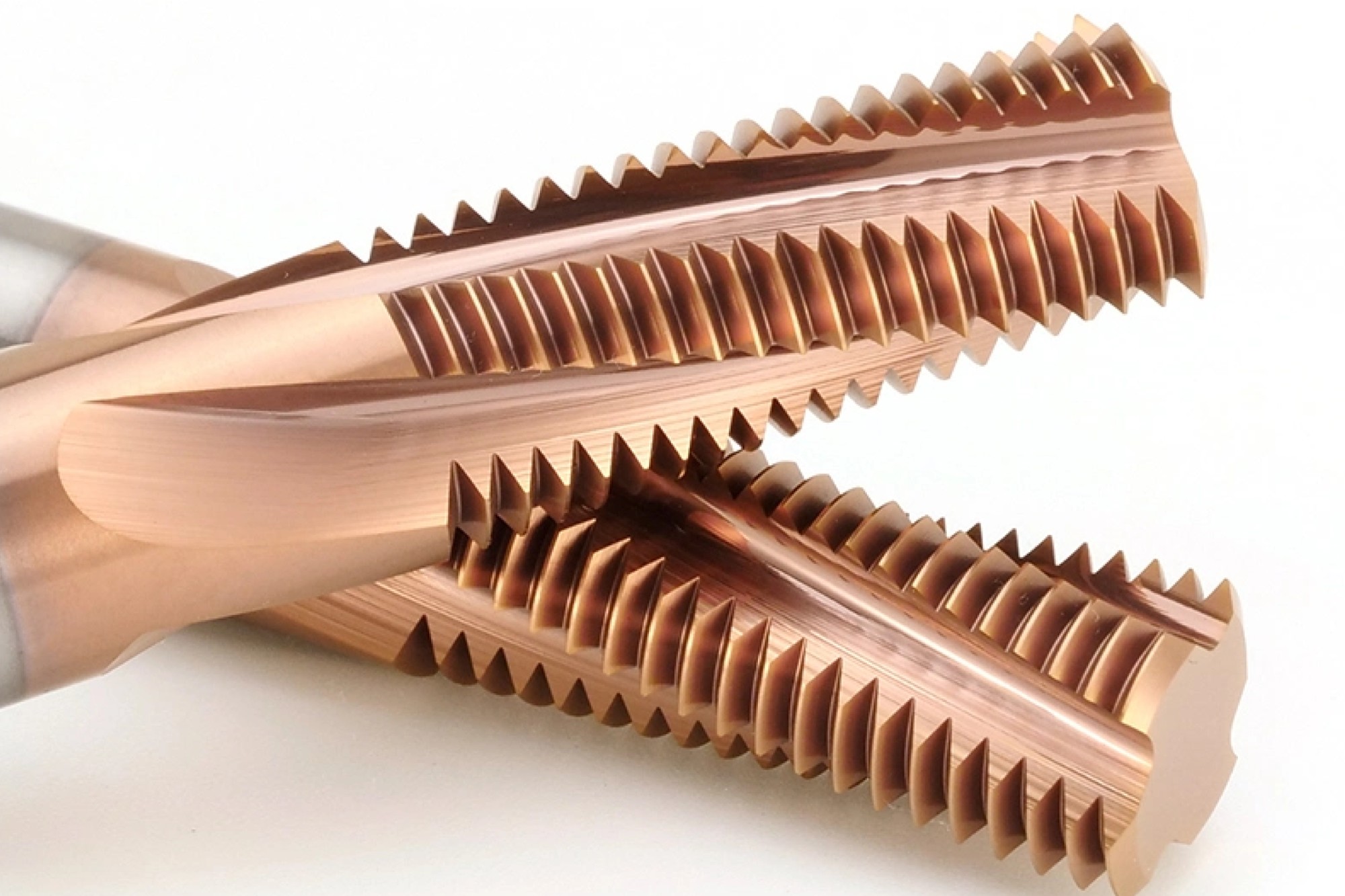

These micro boring tools are made from high-quality solid carbide and are known for their high hardness, strength, and excellent wear resistance. They are designed to provide precise and accurate cuts and highly tolerate errors. The tools also feature a variety of geometries, including different radii and angles, to suit different applications.

The carbide micro boring bar adopts a full carbide cutter body to suppress processing vibrations effectively. It provides precise machining accuracy and a good surface finish. The micro-diameter design is beneficial for narrow aperture processing, copying, and chamfering workpieces.

Benefits

These tools have high heat resistance and exceptional toughness, making them ideal for machining hardened steels. They are also well-suited for machining cast materials and special alloys. They can be used at high cutting speeds with enhanced thermal shock resistance.

One benefit of TruCut Micro Boring tools is their accuracy and precision. They are designed to provide precise cuts, which can improve the quality of finished parts. They also offer versatility and flexibility, as they come in many styles and sizes and can be used for various cutting applications and materials. Additionally, they are durable and can be re-sharpened multiple times, reducing the need for frequent replacements.

Innovative Multi-Task Micro Tools:TruCut introduces innovative micro tools that can multi-task. A single tool can be used for boring, turning, grooving, and profiling. It features a unique chip breaker and flute design, enabling the machining of the material without a pilot hole.

This tool reduces machining cycle time and the number of tools required, achieving high productivity. It is an excellent solution for machining stainless steels, super alloys, and other difficult materials that create curly chips around the tool and application. It can also be used with a wide range of materials for general purposes.

Application

This family of tools is mainly designed for the internal machining miniature parts, mostly used in the aerospace and miniature components industries. It consists of various cutting geometries of carbide inserts and tool holders for internal machining applications. These tools are also applied in the manufacturing and processing precision small parts, such as professional medical equipment, electronics, chemicals, and other industries.

This tool penetrates the workpiece and produces a hole compliant with the minimum diameter it allows. Depending on the workpiece material and machine power, the tool can penetrate the material in one or several passes. Multiple radial passes can enlarge the hole. The tool is equipped with an additional cutting edge across the main front edge, producing an additional 45-degree chamfer on the workpiece without stopping the spindle or the processing operation.

For more details:

www.trucut-tool.com

sales@trucut-tool.com

+91 7397771855 | +91 7397723118

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.