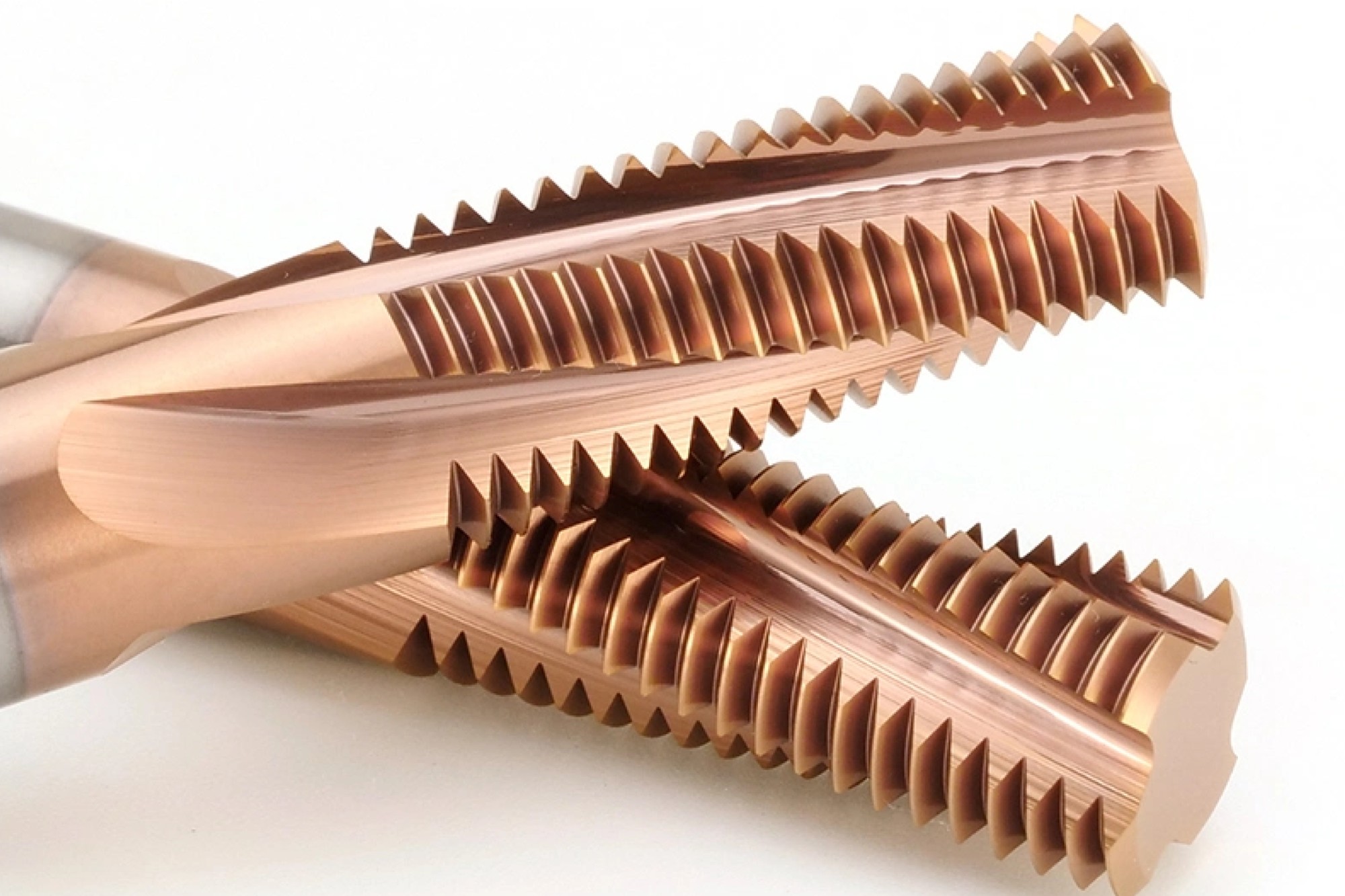

Precision thread milling for superior performance

By Staff Report January 29, 2025 7:07 pm IST

TruCut Thread Mills deliver high-quality, accurate threads with reduced cutting pressure and superior surface finish. Their versatility, reliability, and advanced coatings ensure long tool life and enhanced machining efficiency.

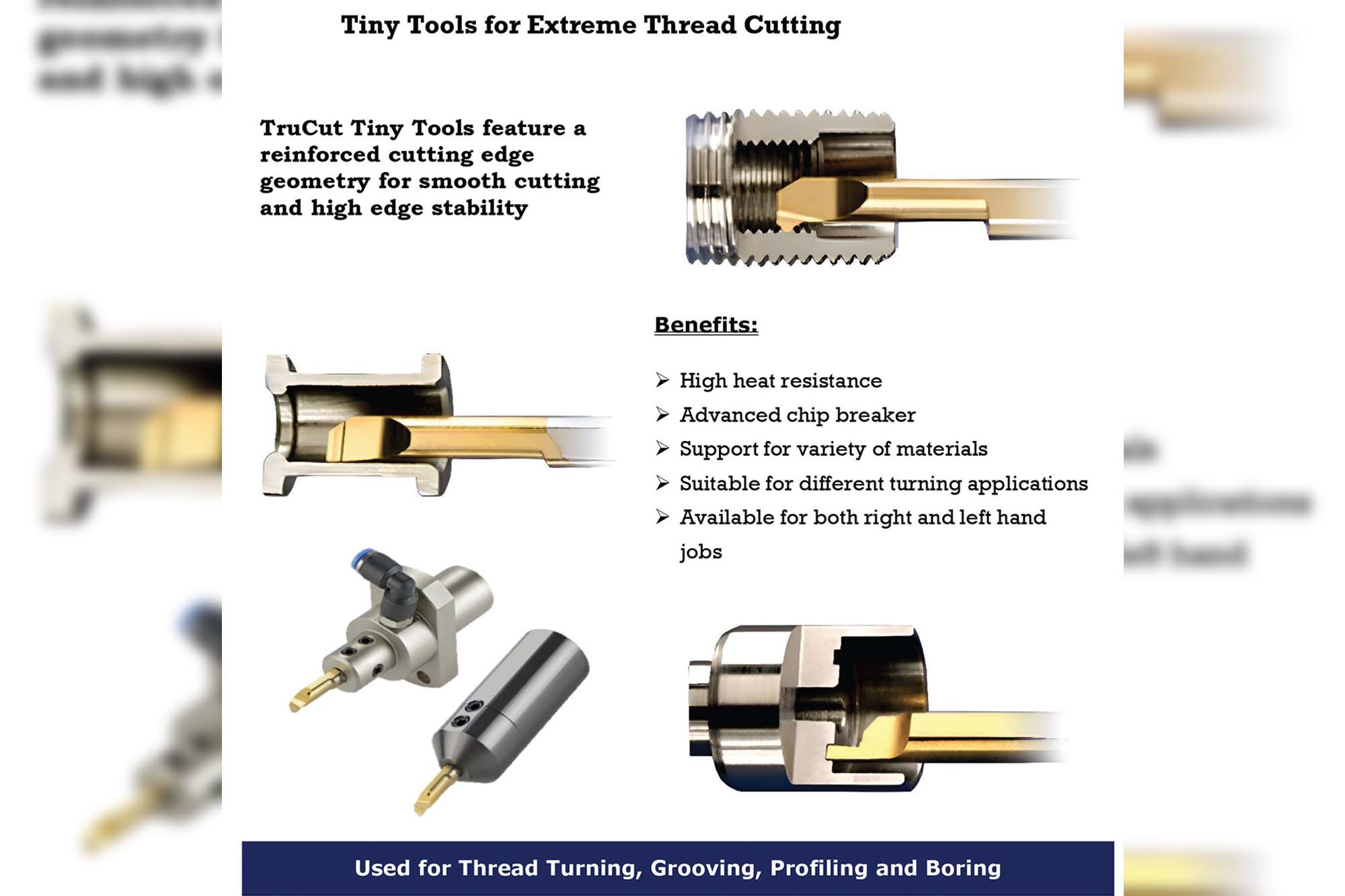

Thread mills are tools designed for an extensive array of applications. They are versatile and cost-effective process tools for anyone with the requirement of cutting a variety of products. They are used on numerically controlled machining centers that have simultaneous, triaxle control and helical interpolation functions.

TruCut Thread Mill cutter ensures secure machining operation with reduced cutting pressure. Thread mills provide high thread quality at a low cost per hole. Compared to general tapping, thread milling is more stable with fewer cutting condition limitations for chip management. Unlike tapping, threads produced through milling can be machined to full depth at high accuracy, even in hardened materials.

Features:

The same tools can be used for left and right-hand threads. A high range of materials and hole diameters can also be thread-milled with the same tool.

Thread milling is a reliable and flexible method of thread production. Synchronisation between spindle speed and feed rate is not required for thread milling. Thread milling can therefore be carried out with any CNC milling machine. It is easy to adopt this process and produce high-quality threads with excellent form and finish.

It is ideal for costlier work pieces where mistakes cannot be tolerated and holes have limited clearance before threading.

Benefits:

TruCut Thread Mills produces threads with high surface finish, sizes and accuracy. It also has high process reliability under variable conditions. Thread mills generate superior burr-free surface finishes and reduce tool inventory costs.

Thread mills have high helix angles that reduce cutting forces and eliminate chatter. Thread is generated in one pass and spiral flutes allow smooth cutting action. It has a longer tool life due to special multi-layer coating.

Advance Threading Solutions:

Using advanced technologies, these cutters guarantee flawless results, minimising machining time and improving the quality of the end product.

Among the most popular variants in the industry are carbide thread milling cutters. These tools are known for their exceptional hardness and wear resistance, ideal for machining particularly tough materials such as hardened steels and special alloys. Tungsten carbide thread milling cutters ensure long tool life and consistent precision, reducing the need for frequent replacement and improving the operational efficiency of machine shops.

Application:

Thread milling cutters are essential tools in machine shops, designed to perform precise threading on a variety of materials, from the hardest metal alloys to technical plastics.

For machine shops requiring maximum flexibility, universal thread milling cutters are the perfect solution. These tools are designed to work efficiently on a wide range of materials and threads, offering excellent performance regardless of the type of machining required. Their versatility makes them an indispensable tool for workshops facing different production challenges.

Thread milling cutters for CNC represent the pinnacle of threading technology. Designed for CNC machines, these milling cutters offer unrivalled precision and repeatability, allowing complex and customised threads to be easily executed. Their integration with CNC systems also ensures optimal management of machining cycles, reducing scrap and optimising the entire production process.

Thread milling cutters are therefore indispensable tools for any machine shop that wishes to improve its productivity and machining quality. With variants available, from tungsten carbide to universal milling cutters, every professional can find the tool best suited to their needs.

For more details:

Web: www.trucut-tool.com

Email: sales@trucut-tool.com

Contact: +91 – 7397771855 | +91 – 7397723118

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.