Precision engineering leads to superior performance and cost efficiency

By Staff Report March 1, 2025 5:00 pm IST

This interview explores TruCut Tools’ advanced manufacturing and customer-driven innovations. Learn from Zuzer T Lokat, Managing Director of TruCut Precision Tools Pvt. Ltd., how their solutions, from exchangeable carbide milling heads to optimised tool geometries, enhance machining efficiency, extend tool life, and drive cost savings for manufacturers worldwide.

How does your investment in advanced tool production and inspection equipment ensure the highest standards of accuracy and consistency in your tools?

We invest in advanced tool production equipment, supported by state-of-the-art inspection machines and micro-level inspection procedures, to ensure that every tool meets the highest standards of accuracy.

We use CNC 5-axis and 7-axis grinding machines to ensure consistent tool performance. Our non-contact 5-axis CMM tool inspection machine guarantees precise geometry and dimensions. The combination of advanced CNC grinding and inspection machines ensures that all tools leave our facility with high quality and consistency.

We ensure the machining industry operates smoothly by providing high-quality products, consistent performance, and timely delivery. We efficiently meet all machining needs with an extensive inventory of catalogue items ready to ship the same day and custom tools available with minimal lead times.

The quality of our products is evident through the use of optimised carbide materials, superior grinding techniques, innovative tool geometries, and advanced tool coatings. Each tool undergoes rigorous inspection and quality control to guarantee consistency and optimal performance. Our tools meet the highest standards in industries where precision and reliability are essential.

What considerations should be taken when selecting the right ball nose end mill for a specific application?

Selecting the appropriate diameter and length of a ball nose end mill is essential for accurate profiling. Smaller diameters are ideal for detailed work, while larger diameters are better suited for roughing and material removal. It’s also important to consider the length of the end mill; longer tools may experience more deflection, which can impact accuracy. Aim to balance your needs to find the best combination of diameter and length for your specific application.

To achieve optimal performance and extend the lifespan of your ball nose end mill, it’s crucial to determine the appropriate speeds and feeds. Maintaining the correct cutting speeds helps prevent overheating and reduces tool wear, while the right feed rates ensure efficient material removal. Always consult the manufacturer’s recommendations and conduct trial runs to identify your specific application’s ideal speeds and feeds.

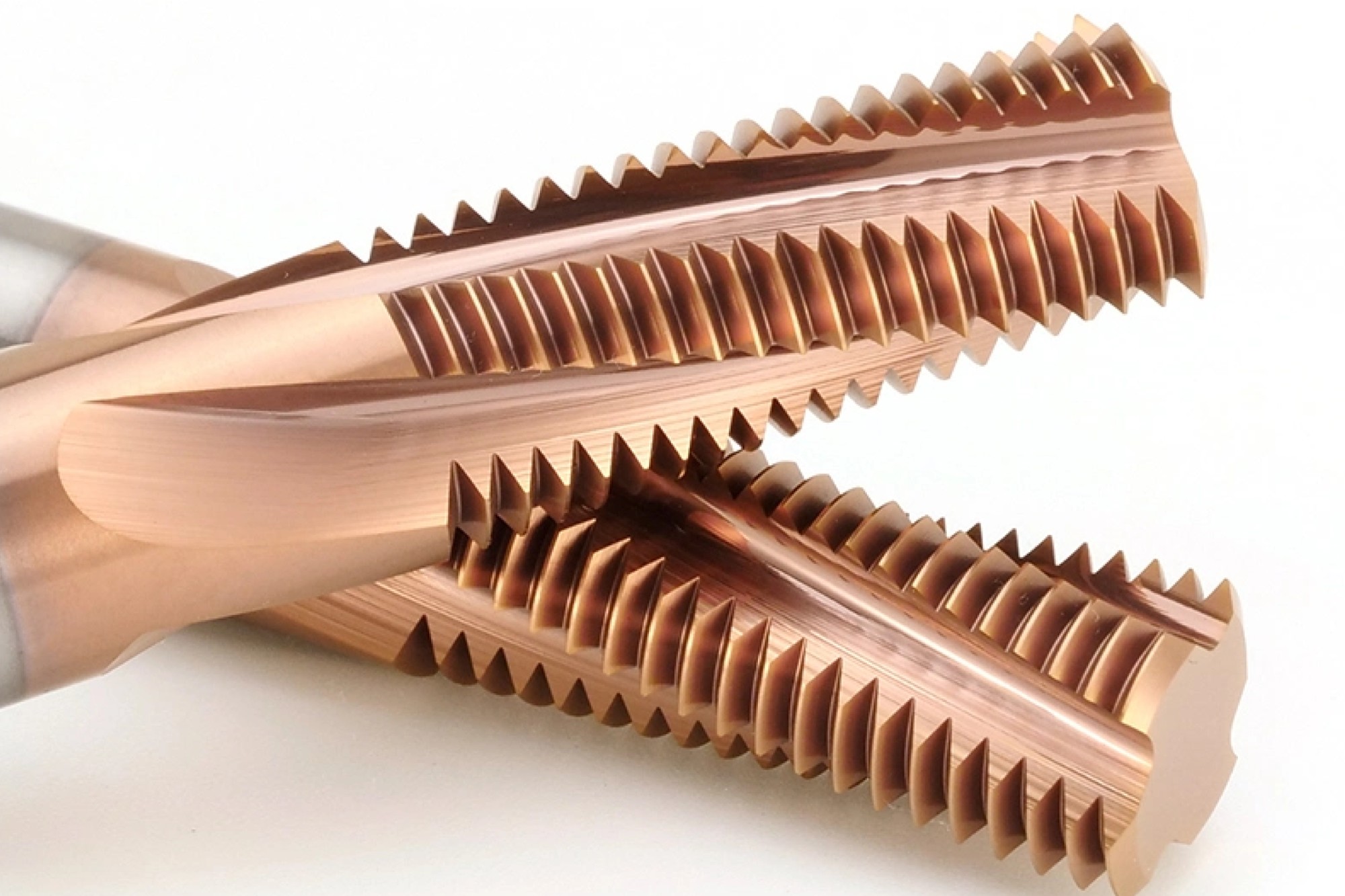

How do exchangeable solid carbide milling heads improve milling efficiency and reduce costs?

The quick and easy exchange of different solid carbide milling head profiles and types optimises milling operations and reduces manufacturing costs. Using exchangeable solid head mills increases productivity. Additionally, having multiple heads enhances flexibility and reduces the need for a costly tooling inventory.

Collaborating closely with customers to understand their rapidly changing machining demands, we address these needs and provide reliable solutions with short lead times on a win-win basis.How do corner radius end mills reduce tool wear and extend tool life?

A solid carbide corner radius end mill with a flared corner radius does not fully complete the radius but allows for greater forgiveness. This tool creates a clean surface finish and eliminates the need for a second finishing operation to remove any markings that may be left behind. In contrast, a corner radius that is not flared provides a full radius on the workpiece, requiring additional setup time to ensure additional no steps.

These end mills offer high wear resistance, enhanced performance, and precision, optimising productivity and flexibility. They are suitable for a variety of applications and for cutting difficult materials.

Consistent and predictable tool life contributes to better performance across materials, with resistance to built-up edge.

How does TruCut utilise customer feedback to drive sales growth and improve customer satisfaction?

Developing a successful strategy requires careful attention to customer feedback. Incorporating this feedback into sales is a complex process that must be executed precisely. Using the right tools and techniques to collect, analyse, and utilise feedback effectively is essential. We are committed to continuously learning to leverage customer feedback, which will help us increase revenue and enhance customer satisfaction.

TruCut Tools is dedicated to making the machining world operate flawlessly by providing quality products, consistent performance, and timely delivery. We maintain a large inventory of all catalogue items, ready to ship on the same day, and offer special custom tools with minimal delivery times.

Our approach guarantees that customers enjoy significant savings and increased productivity over time.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.