Optimising milling operations is the future of cutting tools

By Staff Report August 31, 2024 5:32 pm IST

Zuzer T Lokat, Director of TruCut Precision Tools, says TruCut is at the forefront of innovation in milling operations, offering advanced Solid Head Mills and customised solutions. Focusing on industry trends, TruCut delivers high-performance tools that improve productivity, flexibility, and reliability in challenging applications.

What factors should be considered when choosing milling tools for high-speed machining applications?

When choosing the appropriate milling cutter, it is essential to consider the cutting power and the processing size of the workpiece. For instance, when selecting the diameter of a face mill cutting tool, ensure that the tool’s power requirements align with the milling machine’s capacity. Key factors in selecting milling tools include the type of material to be machined, the amount of material to remove, the desired surface finish, and the machine’s capabilities. Consider your budget, the machine’s size and power, and the type of material you need to work with to decide – what kind of milling machine is the best application for your needs.

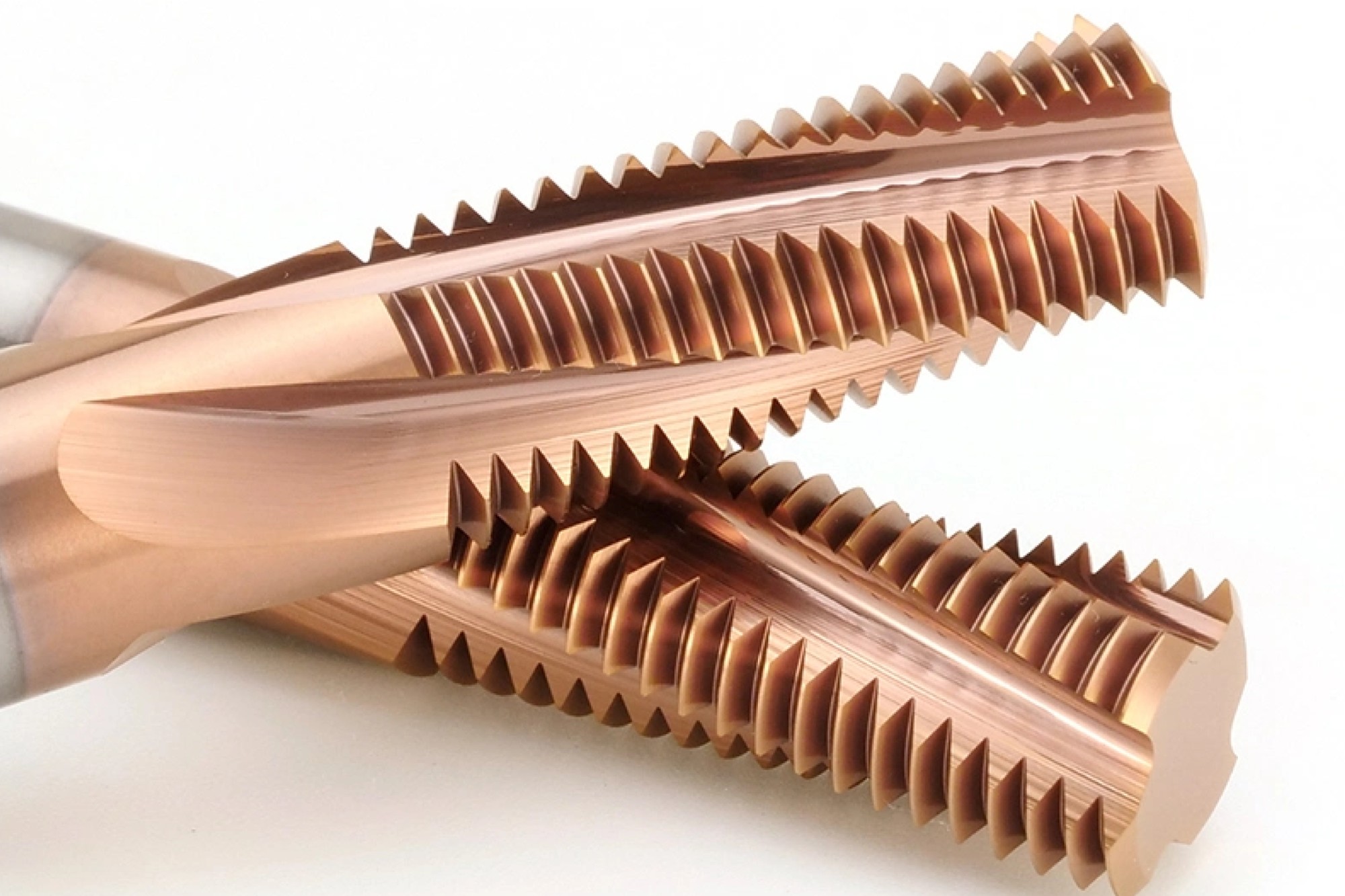

What are the key benefits of using TruCut Solid Head Mills for milling operations?

The TruCut Solid Head Mills offer several advantages for milling operations. They allow quick and easy exchange between solid carbide Milling head profiles and types, optimizing milling operations while reducing manufacturing costs. Further, productivity increases with the use of exchangeable solid head mills. Furthermore, using multiple heads enhances flexibility and minimises the need for expensive tooling inventory.

How can the choice of cutting tool geometry impact the surface finish and tool life in milling operations?

A well-designed cutting tool with appropriate geometry can help extend the tool’s life and improve the cutting performance. The primary machine goal is to achieve the most efficient separation of chips from the workspace. Cutting tools for metal cutting have many shapes, described by their angles or geometries. Each tool shape is usable for a specific purpose in metal cutting.

What advanced coatings materials do milling tools utilise in high-temperature machining environments?

Tools coated with titanium aluminium nitride (TiAlN) can withstand the high temperatures generated during machining, reducing wear and extending tool life. The coating features strong adhesion to the carbide substrate, preventing delamination. The alternating layers check cracks from propagation to fracture, offering resistance to wear and oxidation.

What makes carbide shanks preferred for TruCut Solid Head Mills in terms of accurate machining?

Due to their excellent rigidity, carbide shanks are preferred for maximum accuracy in machining. Since only the head is indexed, the setup is simplified, and machine downtime decreases considerably. Repeatability and accuracy are maintained due to contact between taper and the face.

Using highly secure solid head mills with a shank interface ensures better performance for roughing and semi-finishing. The solid carbide shank offers the highest levels of precision and stability, mainly for deep pocketing and long overhang applications.

Which materials are Solid Head Mills especially effective at machining?

These Solid Head Mills offer high wear resistance, improved performance, and precision that optimise productivity and flexibility. They are better suited for various applications with difficult-to-cut materials. Their consistent and predictable tool life ensures better performance across materials while resisting built-up edge issues.

What emerging technologies are shaping the future of machine tools?

TruCut focuses on technological advancements and industry trends. We are the perfect partner for developing and producing primary and secondary aircraft components. TruCut offers you the most comprehensive range of solid carbide tools for metal and composite materials available anywhere in the world from a single source. Our flexible machining solutions for the aerospace industry set new standards for the highest possible productivity and process reliability through technical support.

For more details visit – www.trucut-tool.com

sales@trucut-tool.com

+91 7397771855 / +91 7397723118

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.