Hi-Performance Helical Solutions for longer tool life

By Staff Report March 28, 2025 12:01 pm IST

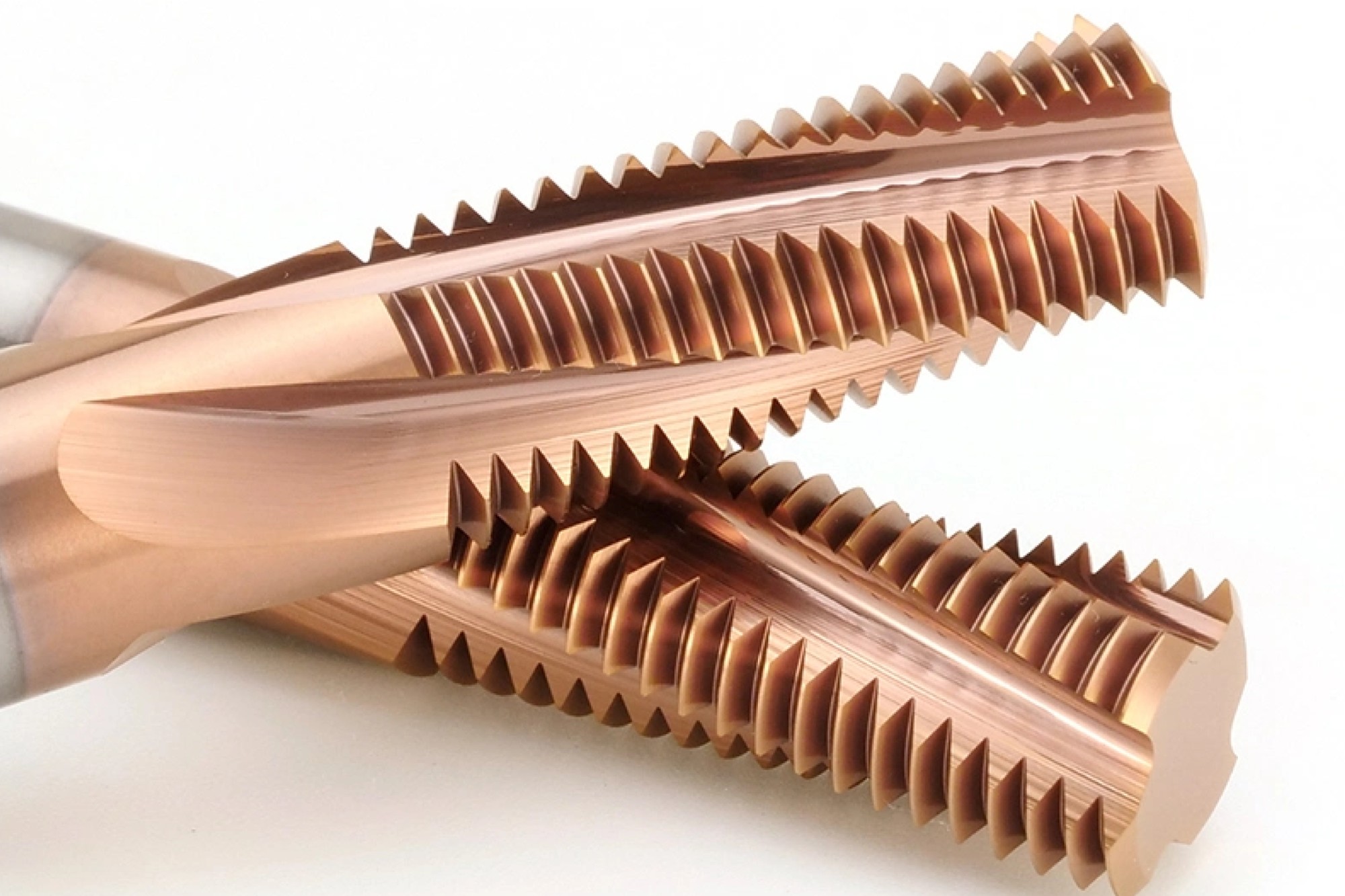

TruCut Variable Helix End Mills reduce vibration, enhance cutting efficiency, and improve tool life. Their advanced geometry ensures stability, optimal chip control, and high-speed productivity, making them ideal for machining tough materials with precision.

High-performance end mills with variable helix or variable pitch geometry have a special design that reduces vibration and improves cutting efficiency. Unlike standard end mills, where all cutting edges hit the material at the same time, these advanced tools change the timing of each cut. This prevents excessive vibration, leading to smoother cutting, longer tool life, and a better surface finish.

Increasing the helix angle improves stock removal and is useful in machining at increased speeds and feeds. A higher helix angle also reduces tool deflection and transfers stress vertically through the spindle rather than horizontally.

Features:

TruCut Variable Helix Endmills are dedicated to original equipment manufacturers and first-tier suppliers where large batches of a single component have to be machined and where processes need to be fully optimised to reduce cycle times, reducing costs per part.

Its enhanced flute design improves chip control and reduces cutting forces, allowing for aggressive speeds and feeds. The appropriate rack angle determines the size and shape of the chip, as well as the pressure and temperature on the tool, for advanced high-speed productivity.

Endmills of TruCut have optimal tool stability, and their engineered core provides robust axial strength. Damping vibration reduces chatter, minimises heat buildup, produces good surface finish, and extends tool life.

Precision tolerance and wide gashing enhance shearing ability, leading to a smoother surface finish and longer tool life. The use of premium ultrafine carbide ensures excellent wear resistance and toughness. Additionally, the CrN coating now offers increased hardness, improved durability, and smooth chip flow, reducing friction for more efficient cutting.

Benefits:

TruCut Variable Helix Endmills can work under low radial force. With lower radial forces, high helix tools can cut through material much more easily with a better Shearing action, leaving an improved surface finish.

As the helix angle increases, the length of the cutting edge engagement will decrease, and the axial force will increase. The slow helix allows the tool to create a large chip, great for hogging out material.Variable helix end mills are suitable for difficult-to-machine steels, stainless steels, and tool steels. These end mills are optimised for titanium alloys, Inconel, nickel alloys, and other high-temperature materials. The variable helix geometry reduces chatter and

vibration, providing greater stability during cutting. This allows for higher cutting speeds.

Powerful End mills:

TruCut Variable Helix End mills are the exact solution for low-power machines. They improve the material removal rate and eliminate vibration. These End mills maximise stock removal and reduce cycle time in most milling operations.

Their unique ground geometry provides excellent surface finish and long tool life while machining at high material removal rates. End mills are used for roughing and finishing operations and, due to their variable pitch, feature excellent chatter-dampening ability

Application:

When selecting tools for a specific application, users must consider several factors, including the material being cut, the required surface finish, and acceptable run times. Additionally, the helix angle of each tool plays a crucial role in performance, affecting chip evacuation, cutting forces, and overall efficiency.

A slow helix end mill creates larger chips, provides greater tool strength, and reduces lifting forces, making it ideal for tougher materials. In contrast, a high helix end mill improves chip evacuation and delivers a superior surface finish but can be more prone to deflection, which may lead to breakage if not controlled properly.

This type of tool runs quieter and smoother due to its efficient shearing action, offering greater stability and less deflection, particularly in thin-wall applications.

For more details:

Website: www.trucut-tool.com

Email: sales@trucut-tool.com

Contact: +91 7397771855 | +91 7397723118

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.