Manufacturing 2024: Metal forming and laser technologies

By OEM Update Editorial December 29, 2023 6:31 pm IST

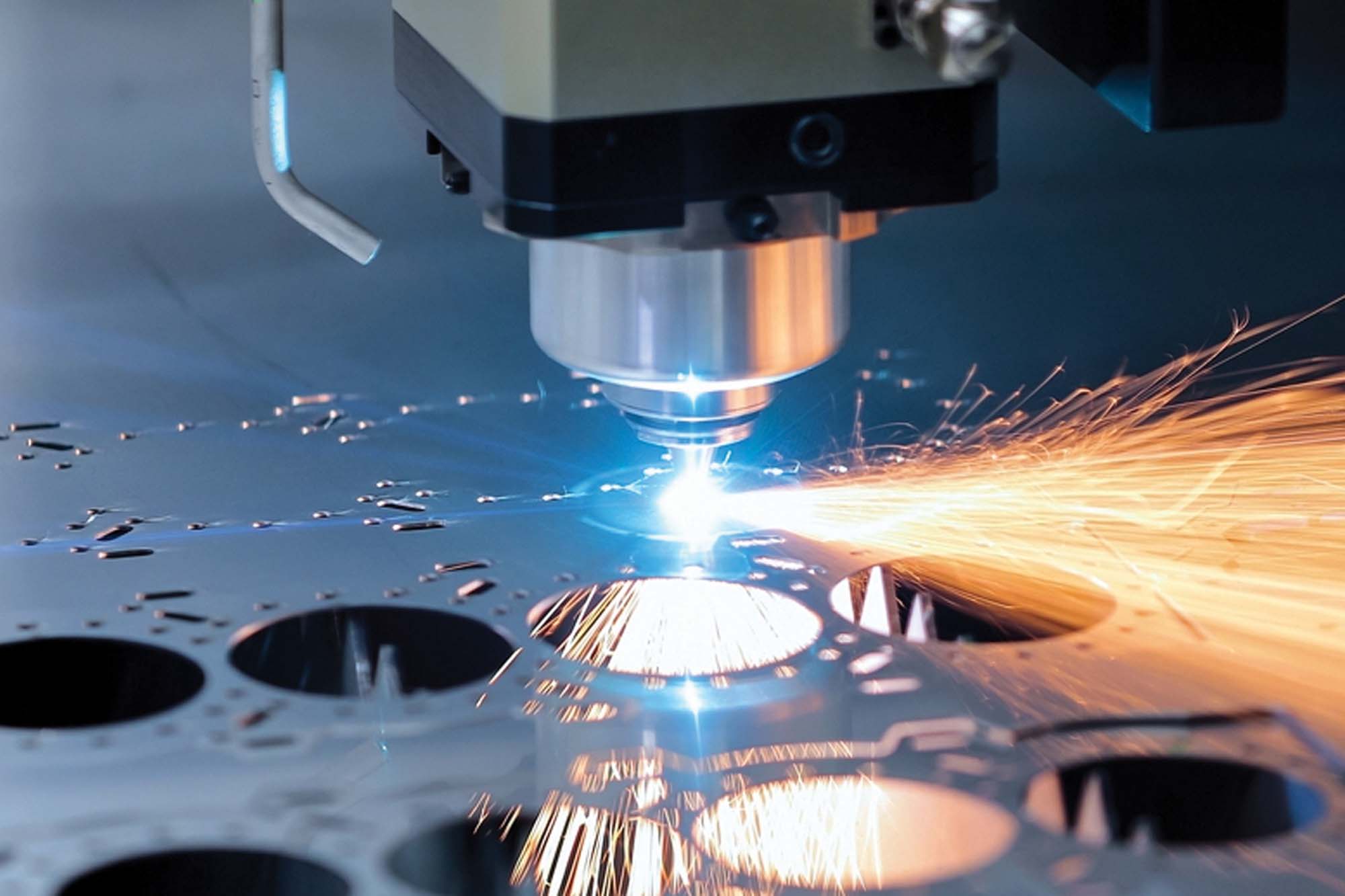

Advancements in metal forming and laser cutting technologies represent an evolution in manufacturing. These progressive techniques impact industrial processes, offering precision and efficiency in shaping metals. Industry experts discuss that through innovative approaches in metal forming and the integration of laser cutting technology, industries now benefit from enhanced productivity, reduced material waste, and intricate design possibilities.

The Indian economy is currently showing a growth rate of 7.6 per cent, as reported by government agencies. Forecasts indicate a promising outlook for the manufacturing sector in the fiscal year 2024. There is a noticeable surge in domestic demand within the sheet metal industry, particularly in the automobile, agriculture, railways, and infrastructure sectors. Companies are keen on expanding their production capabilities, specifically emphasising incorporating automation into their processes.

By 2030, India is anticipated to secure the position of the world’s third-largest economy, fostering demand for various products such as advanced automation, cutting-edge welding technology, and innovative press solutions tailored to meet the needs of emerging industries like Aerospace and EVs.

Manufacturing Outlook 2024

The industry is in line with significant evolution in 2024, particularly regarding new standards and technology. Smart manufacturing is expected to play a crucial role by using digitalisation to transform processes. This shift promises real-time insights into shop floor operations, offering valuable data for individual processes. Mr. CS Sharma, Joint Director of the Quality Council of India, adds, “The integration of AI-driven tools with this data is anticipated to provide inputs for streamlining operations, identifying areas for improvement, and making informed decisions about production plans and facilities. Unlike the current reactive approach to sudden inputs, the future envisions a proactive, data-driven system that ensures robustness and sustainability. The upcoming year is projected to witness a transition towards adopting new technologies, embracing Industry 4.0, and emphasising quality 4.0, including AI and smart manufacturing interventions. Expectations are high for a dynamic and transformative landscape in the industry.”

Upcoming Trends

Ravichandran Duraiswamy, Sr. Manager – Product Management, Messer Cutting Systems India Pvt Ltd, adds, “In the upcoming year, the focus is on enhancing both power and features in technology. The goal is to combine high power with advanced capabilities such as mixed gases and integrated laser features. The emphasis lies in developing software that ensures a seamless cutting process, eliminating any visible markings at the end. The year ahead is expected to prioritise high power and feature-rich technology synergy to elevate productivity and quality.

Laser Cutting Technology

Mr. Avinash Khare, Consultant and corporate Trainer, New Manufacturing Technology and Automation, notes that exciting developments are underway in laser cutting technology. A notable trend involves the exploration of multimodal lasers, allowing for simultaneous use of various sheets without changing equipment or adjusting length manually. This innovation enables automatic adaptation of laser sharpness based on the material and its thickness, offering precision whether cutting apples or bread. Locus laser cutting is also gaining prominence, featuring a smaller spot that can be moved strategically for wider cuts or thicker plates. This method allows precise control over curves and beveling and minimises unwanted debris. Thermography Control makes waves in welding, enabling heat sensing and real-time modulation of power and process parameters for effective control. The future is expected to be dominated by adaptive automation, revolutionising these technologies for enhanced efficiency and precision.

AI

Meanwhile, AI adoption in the Indian industry has yet to reach its full potential. Globally, Al’s trend is toward efficient shop floors with minimal workforce and streamlined material movement. Just-in-time manufacturing is gaining popularity worldwide. The global scenario shows a growing inclination towards automation, where AI is considered a key tool for optimal results in manufacturing processes. In India, the adoption of new technologies tends to start slow but once embraced, growth is rapid and phenomenal, as seen in the history of technologies like mobile phones and colour TVs. It’s only a matter of time before the Indian industry fully embraces and integrates AI for greater efficiency.

Welding Process

Mr. Srinivas Badam, Sr. General Manager- Head Operations, TATA AUTOCOMP Gotion Green Energy Solutions, contributes, “Welding processes lack real-time monitoring in the current scenario. This proves a significant gap in the technology. Looking ahead, there’s a notable focus on innovating laser weld monitoring. This aspect is crucial for the future, with various activities and advancements in progress. In the manufacturing industry, especially in battery technology, OEMs aim to ensure real-time welding correctness, strength, and alignment. Traditionally, the manual and tedious process of measuring welding strength is being reevaluated, with ongoing trials exploring the implementation of online or in-line weld monitoring systems. This shift is anticipated to be the next crucial innovation in welding technology.”

Digital technology and automation

AI is making strides in various phases, particularly post-welding processes such as optical inspection. Mr Khare thinks that with the help of AI, inspections for job distortion or dimensions can be efficiently conducted. AI is already used for digital inspections, employing digital cameras and robots to identify abnormalities, missing components, or any visible defects in assemblies. This marks the primary application of AI in this context.

The second application of AI involves addressing vibrations in machines and robots operating at high speeds. AI algorithms suppress and eliminate these vibrations, enhancing overall quality. Companies like FANUC are actively working on implementing AI to mitigate vibrations in their robots. This approach is not limited to robotics but also to machining and welding. Digitalisation and Industry 4.0 concepts are integral to welding, with modern welding sources featuring automation and Industry 4.0 compatibility. This enables remote monitoring of various welding parameters, such as the number of welds, current, energy, and deposit volume, enhancing data automation’s capabilities in welding and laser welding. This trend is already gaining momentum and is expected to expand further.

Sustainability

As per Mr.Badam, sustainability depends on availability, specifically the availability of laser crystals and local technology development. In the initial period, there was a huge reliance on imports from China and Europe for welding technology in battery packs. However, the landscape is changing, with numerous suppliers introducing in-house welding technologies. Despite challenges in sustainability and timely availability, significant developments are underway. There’s optimism for the emergence of more local developers in the battery segment, marking a positive trend for the coming year.

The sheet metal industry consistently faces challenges due to reliance on skilled labour. Niraj Seth, President, Amada (India) Pvt. Ltd adds, “New products and technologies aim to reduce this dependence by offering automation solutions, including robotics. These solutions have gained substantial popularity in advanced nations like Japan and America, while in India, we actively advocate for robotic bending machines and comprehensive automation systems.

Quality standards

ISO sets the benchmark for global standards and protocols for sheet metal cutting or material processing, complemented by standards from national bodies like BIS, ensuring material reliability and quality. While precision standards for cutting are less apparent, the focus shifts to advanced technologies. Laser-based cutting, specifically high-powered laser technology, emerges as a forefront choice, promising enhanced precision and process optimisation, aligning with global market demands.

Compliance with global norms becomes imperative for the competitiveness of the Indian industry. Adopting cutting-edge technologies on shop floors is emphasised, emphasising the need to adhere to international standards. Mr. Sharma notes that the Quality Council of India has yet to initiate specific standards for material cutting, and the flexibility to incorporate local requirements driven by industry associations or specific sectors remains open. Initiatives in other sectors, such as drones, medical devices, and AYUSH products, highlight the potential for defining standards in the cutting processes domain, aligning with the evolving needs of the industry.

Cost Effectiveness in the manufacturing

Cost-effectiveness in cutting processes involves a strategic focus on boosting productivity, as per Mr. Duraiswamy. This is achieved by increasing cutting speeds, reducing the cutting time and minimising gas consumption. Advanced technologies, such as using nitrogen generators to convert atmospheric air into nitrogen, play a pivotal role in achieving these goals. This approach proves economically beneficial compared to purchasing large quantities of liquid gas. Additionally, emerging technologies involve mixed gases, typically 95% nitrogen and 2-3% oxygen, offering higher cutting speeds and improved quality. These innovations, still in developmental stages, are anticipated to be widely adopted by manufacturers shortly, promising more efficient cutting processes and significantly lowering the cost per part.

===================

Niraj Seth, President, Amada (India) Pvt. Ltd.

“With India’s economy growing at 7.6 percent and a surge in domestic demand, companies are actively incorporating automation to expand production capabilities, transforming the sheet metal industry.”

Mr. CS Sharma, Joint Director, Quality Council of India

“Smart manufacturing and Industry 4.0 redefine quality standards with AI-driven tools and real-time data, ensuring a proactive, data-driven system for robust and sustainable operations.”

Mr. Ravichandran Duraiswamy, Sr. Manager – Product Management, Messer Cutting Systems India Pvt Ltd

“The aim for 2024 is to synergise high power and advanced features in laser technology, emphasising seamless cutting processes and cost-effective solutions through integrating mixed gases for optimal results in manufacturing.”

Mr. Avinash Khare, Consultant & Corporate Trainer, New Manufacturing Technology and Automation

“Developments in laser cutting technology, including multimodal lasers and locus laser cutting, showcase the future of adaptive automation for enhanced efficiency and precision in metal forming.”

Mr. Srinivas Badam, Sr. General Manager-Head Operations, TATA AUTOCOMP Gotion Green Energy Solutions Pvt LTD

“The future of welding hinges on innovating laser weld monitoring, especially in battery technology. The shift to online monitoring systems is the next crucial innovation, promising sustainability and positive advancements in the coming year.”

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.