Flow along with automation

By Staff Report March 1, 2025 12:11 pm IST

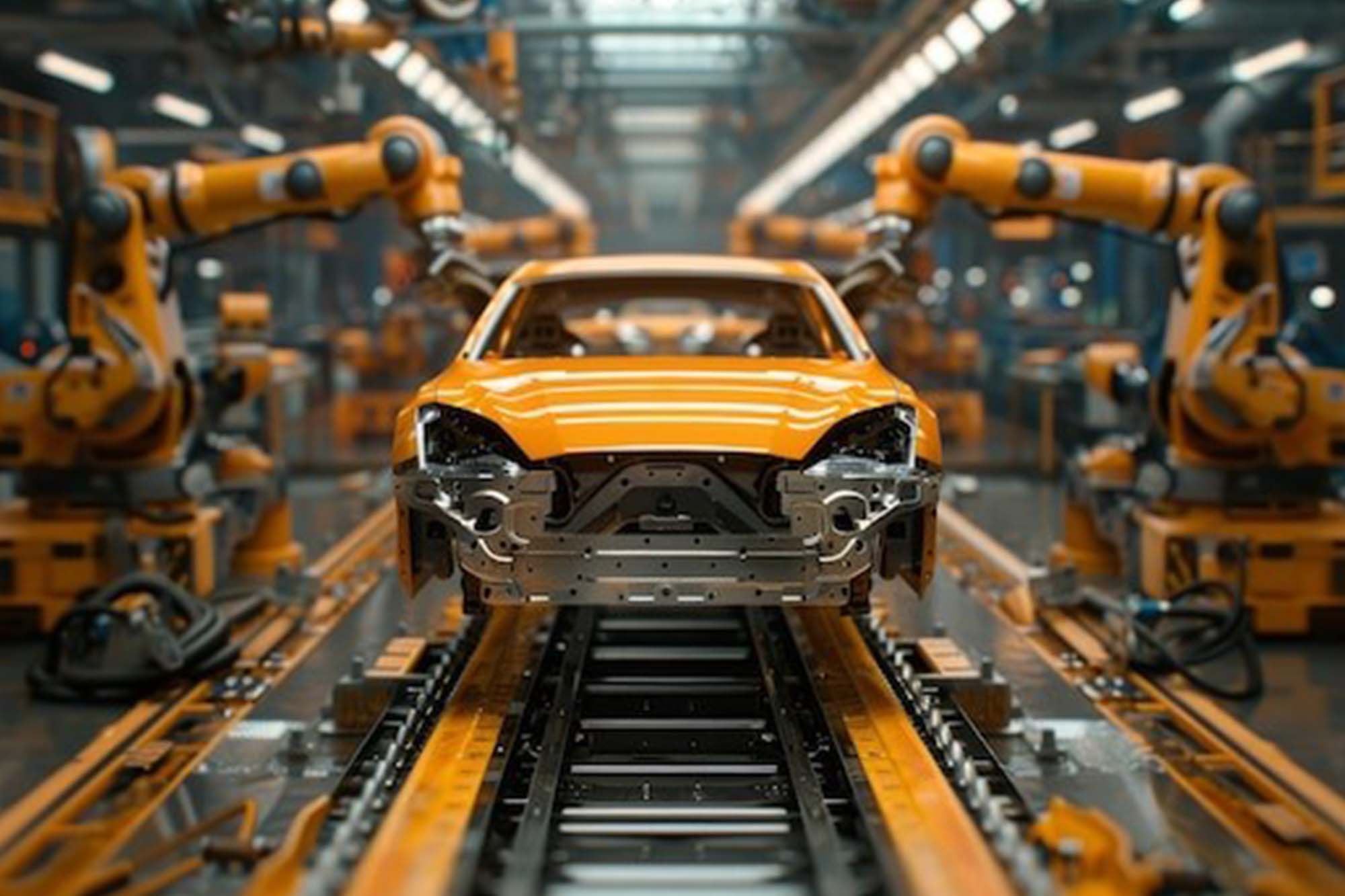

We are embracing futuristic technologies in our work processes. Workflow automation is an admirable process that allows us to automate business tasks using software. This software-based approach automates business tasks, allowing for more efficient project management with minimal human intervention while still keeping human input in decision-making. When implemented effectively, it enhances productivity by routinely executing tasks.

A delegate at an automation exhibition in India shared an intriguing experience from his visit to Japan. While there, he decided to explore a factory over the weekend and reached out to a colleague to arrange a tour. With Japan increasingly embracing a four-day workweek, a Saturday visit seemed off the charts. Instead of turning him down, the colleague swiftly generated a day pass, granting him access to the facility. The delegates followed a guided route via a map that marked essential amenities like restrooms, drinking water, and vending machines for food. The tour was well-secured, and to his surprise, work was still in progress. Some machines were fully operating, and production was happening regularly. The updates and outputs were prominently displayed, showcasing a seamlessly automated operation.

This level of automation aligns with a phrase once highlighted in The New York Times: “Robots Making Robots.” The world follows the innovations Japan creates, and their ahead-of-time thinking keeps them ahead. Also, with the declining young population, countries like Japan are embracing workflow automation wholeheartedly. There are many factories where even humans are deployed, but the machines take over at night, operating unassisted in a dimly lit environment. A lone night watchman patrols the factory floor, flashlight in hand, as the machines methodically mill metal castings weighing several tons and transport them across the plant. What stands out is the non-uniform movement of the machines—unlike traditional automation, where synchronised operations are the norm, each machine here works independently. A computerised system directs each machine tool to switch tasks, adjust speed, or realign priorities perfectly harmoniously with the overarching production plan.

One of the most remarkable examples of such automation is the Yamazaki plant, which commenced operations in October 2023 following an $18.6 million investment. Its high level of integration and synchronised machine network has made it a global benchmark for “manless plants.” Experts regard Yamazaki Machinery Works as one of Japan’s most advanced manufacturing facilities. Similarly, Sumitomo Electric Industries Ltd. has also embraced full-scale automation, launching a cutting-edge, robotised plant in Hokkaido dedicated to producing ultra-hard metal alloys.

Japan’s manufacturing landscape is transforming. Factory buildings are no longer just workplaces; they are hubs of autonomous innovation, redefining the future of industrial production.

Indian manufacturing industry

P.G. Jadeja, CMD, Jyoti CNC Automation Limited, shares, “Today, India is progressing towards increasing its manufacturing sector’s contribution to approximately 25% of GDP over the next five to seven years, up from 15-16%. The government is implementing various policies, including Production-Linked Incentive (PLI) schemes, to support this growth.”

The world is closely watching India’s expanding manufacturing sector. With approximately 7 lakh manufacturing companies, the industry was valued at USD 329.43 billion in 2024. As the government continues to push for growth and investment in manufacturing, the numbers are rising daily. The rapid expansion requires automation to streamline routine tasks, allowing skilled professionals to focus on innovation and cutting-edge technologies.

Challenges and solutions

AI-driven workflow automation presents numerous challenges, but they can be mitigated strategically. Sobin S, Regional Institutional Business Manager at Volvo Eicher Commercial Vehicles, shares the challenges faced by the organisation and how they were resolved. He thinks that one of the major challenges is data quality and availability, as AI models rely on high-quality, comprehensive data. Poor data quality or fragmented sources can hinder AI performance. To address this, businesses should conduct data audits, implement robust data-cleaning practices, deploy centralised data management platforms, and establish strong data-governance policies.

Integration with legacy systems can also be complex, as older infrastructure often lacks the flexibility required for seamless AI adoption. Businesses can overcome this by implementing middleware solutions, using API integrations, adopting phased migration strategies, and collaborating closely with IT teams to ensure smooth transitions.

The high initial investment costs of AI implementation can deter some organisations. To ease financial burdens and balance costs, businesses should start with small-scale pilot projects, opt for cloud-based AI services, conduct thorough cost-benefit analyses, and explore partnerships or government funding opportunities.

Data security and compliance are critical. AI automation involves handling sensitive data. Advanced encryption techniques, strict access controls, regular security audits, and compliance monitoring tools should be employed to protect data and adhere to industry regulations.

Additionally, AI models may produce inaccurate results or reinforce biases present in training data. To enhance model accuracy and fairness, organisations can use diverse datasets, conduct regular model validation, implement bias detection frameworks, and establish ongoing performance monitoring.

Another obstacle to successful automation is the lack of AI expertise within organisations. Businesses should invest in hiring AI specialists, provide structured training programs, encourage knowledge-sharing sessions, and collaborate with AI consulting firms for expert guidance.

Finally, defining clear objectives and key performance indicators (KPIs) will measure your AI automation success. Organisations should set SMART goals, track relevant KPIs such as efficiency and cost savings, use data-driven insights, and conduct periodic reviews to refine their strategies.

Addressing Job ScareAutomation is perceived as threatening the workforce in an already scattered job market. However, workflow automation helps by shifting workforce dynamics from repetitive manual tasks to the management and optimisation of automated systems. Automation primarily enhances human capabilities. While some routine tasks may be automated, human expertise remains essential for programming, maintenance, oversight, and continuous improvement. This shift creates new roles and opportunities, such as Automation Engineers, Data Analysts, and IT Developers. It will also encourage upskilling and reskilling among existing employees, empowering them to take on more complex and strategic responsibilities. Automation attracts younger talent keen to use digital tools via smartphones and tablets, enriching the workforce with tech-savvy professionals ready to adapt to evolving manufacturing needs. The overall impact is a transformation of existing roles and higher-value jobs rather than widespread job displacement.

Case Study

Many manufacturing processes benefited from workflow automation, starting from application engineering, supply chain, production, engineering, quality, customer management, etc. Mohan Surendran, Plant Head at Lauritz Knudsen Electrical & Automation, shares the case where workflow automation assisted his organisation. He shares, “Out of all the manufacturing processes, quality function gained the most from the workflow automation. The quality function had a lot of mundane activity, which needs to be recorded for future referencing. Upon automating the process, we reduced the verification time, consolidation, traceability, and human errors. The in-process inspection was completely automated from inward part consolidation, sampling, drawing verification, capturing data and record creation.”

It helped improve efficiency by ending paper-based handoffs and enabling the parallel processing of tasks rather than sequential workflows. This function traditionally involved tedious documentation and verification tasks prone to human error.

By digitising workflows via an O365 platform integrated with SharePoint, the organisation automated the components list uploads, sampling calculations, data entry, and report generation.

Key improvements included a 40–60% increase in verification speed through real-time data capture and automated reporting and a 15–30% reduction in errors by using pre-populated reference values and visual part drawings. The transition to paperless processes reduced costs and environmental impact while improving compliance. Additionally, material clearance time was significantly reduced from 1.5 to 0.5 days, enhancing overall customer satisfaction.

These changes streamlined traceability, enabled real-time corrective actions, and freed resources for higher-value tasks, making quality control a standout beneficiary of automation.

Implementation challenges included cybersecurity risks, legacy system integration, cross-platform complexity, resistance to change, customisation demands, and resource constraints. Cybersecurity risks were mitigated through pre-deployment certification from cybersecurity experts, while Excel macros bridged the gaps between SAP and new digital tools to address legacy system integration. Cross-platform complexity was overcome by training teams in HTML, text scripts, and Power Automate for seamless data transformation. A phased rollout, co-designed with function heads and users, fostered buy-in and eased adoption through mobile-friendly solutions. Flexible workflows with decision points replaced rigid automation to accommodate engineered-to-order products, meeting customisation demands. Resource constraints were managed through online training and knowledge-sharing sessions, accelerating skill development in new programming languages.

Despite these challenges, the successful deployment of digital solutions was driven by strong leadership, with the BU Head and Plant Director strongly advocating digital transformation. A dedicated and focused team worked to achieve continuous improvement, while collaboration with other factories created synergistic opportunities to elevate the benefits of digital implementation.

Dr. Bijal Sanghvi, Managing Director of Axis Solutions, says that the future of workflow automation in manufacturing lies in AI-driven decision-making, IoT-enabled smart factories, and hyper-automation integrating ERP, CRM, and predictive analytics software. To stay ahead, manufacturers invest in scalable digital infrastructure, upskill or reskill their workforce for new technology adoption, and embrace data-driven strategies for real-time optimisation. Proactive adoption innovations will ensure agility, efficiency, and sustained competitive advantage in the evolving industrial landscape.

—————————————————————–

Quotes-

Dr. Bijal Sanghvi, Managing Director, Axis Solutions

Workflow automation reshapes workforce dynamics by shifting employees from repetitive and monotonous tasks to higher-value roles, fostering innovation, efficiency, and effectiveness. While it may reduce manual labour in certain areas, it creates new opportunities in automation management, data analytics, and system optimisation.

Shubhankar Chatterji, Chief Supply Chain Officer, Cummins India

Workflow automation offers significant advantages across a wide spectrum of manufacturing processes by streamlining operations, reducing manual intervention, and improving overall efficiency. Key beneficial processes include production monitoring and analytics, predictive maintenance and asset management, quality control and defect reduction, ergonomics risk assessment, automated production scheduling and sequencing, inventory management, and supply chain and logistics optimisation.

Mohan Surendran, Plant Head at Lauritz Knudsen Electrical & Automation

The successful deployment of digital solutions in the manufacturing industry is attributed to strong leadership, focused effort, and collaboration with other factories.

Sobin S. Regional Institutional Business Manager Volvo Eicher Commercial Vehicles

Traditional quality inspection processes are labour-intensive and prone to human error. Using computer vision, AI-powered visual inspection systems can quickly and accurately identify product defects .

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.