Enabling a Fault-free O&G sector

By OEM Update Editorial October 15, 2019 6:14 pm IST

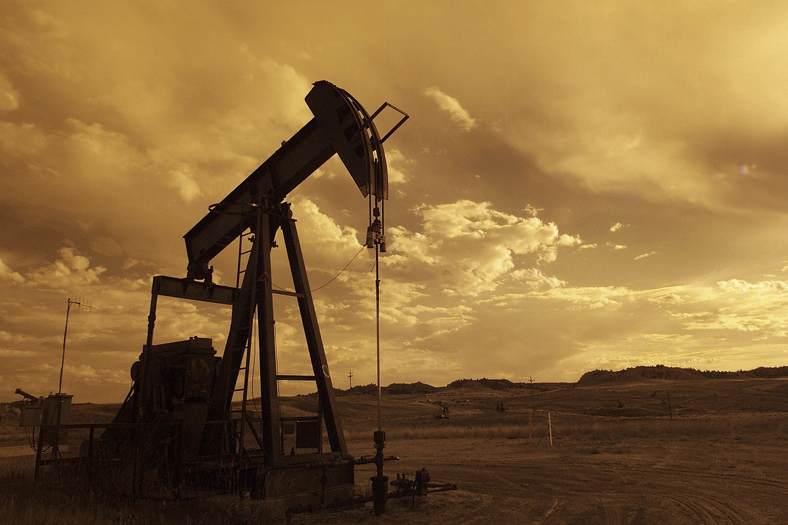

India’s O&G sector has been in the news for quite some time, for reasons right and wrong. Here, we have industry experts talking about automation, safe monitoring, key challenges and the most important ‘safety’ of the people and products associated with the O&G sector.

T he oil and gas sector is among the eight core industries in India and our economic growth is closely related to energy demand. Therefore, the need for oil and gas is projected to grow more, thereby making the sector quite conducive for investments.

The O&G of India

India retained its spot as the third largest consumer of oil in the world in 2017. Hence, it is all the more critical for O&G industry in India to look at technological intervention in their processes to optimise operations and maximise production, ensure safety of man and machinery, all the while making the most efficient use of resources. Anil Bhatia Vice President and Managing Director, Emerson Automation Solutions – India says, “Few of the largest O&G facilities are automated by Emerson in India, enabling access to a global network of automation experts and process management capabilities — from the reservoir to production, through transmission and gas processing.”

Key operational challenges in the oil and gas industry

The government has also launched various exploration programmes like Hydrocarbon Exploration, Licensing Policy and Discovered Small Field Policy to boost India’s hydrocarbon resources and cut down import dependence. Despite the rapid development taking place in this sector, there are still some areas of concern that require immediate attention. Niraj Thanvi, Director, O&G Segment, Schneider Electric-India lists down the following challenges that the sector is facing as we speak:

- Environmental impacts: Oil industry holds a major potential of hazards for the environment, and may impact it at different levels: air, water, soil, and consequently all living beings on our planet. Within this context, the most widespread and dangerous consequence of oil and gas industry activities is pollution. Pollution is associated with virtually all activities throughout all the stages of oil and gas production, from exploratory activities to refining. Also, water contamination is also due to effluent, wash water and cooling water discharges, and seepage from storage and waste tanks. Particulate emissions into the atmosphere are generated during operations at production and refining plants. Accidents that impact the environment, such as large oil spills, leaks, fires and explosions on plants.

- Technology constraints: In India, spurt of exploration activities have started in the shallow basins and onshore assets. It is believed that ultra-deep-water and deep-water oil & gas resources would play a vital role in increasing the domestic production. However, the sector has limited technical and monetary experience to perform exploration and development activities. This provides an opportunity for companies to provide technology that helps to streamline operations to meet such challenges.

- Safety – People, asset and society: Many organisations still use antiquated check-in procedures to ensure the ongoing safety of employees. This approach has proven it is not capable of responding fast enough, in real time to make a difference make your operation safe. Adopting asset monitoring program that incorporates active monitoring far outclasses manual check-in processes or spot-checks and greatly improves your organisation’s ability to collaboratively respond to safety incidents at any moment.

Navigating through the changing regulatory environment

Regulatory compliances are mainly focused into operational safety, environmental protection, waste reduction, power quality improvements and product quality which are ultimately going to benefit Industry in their healthy operations. Interestingly, industry leaders are aspiring to set their high standards and make a difference in market with their safety and quality records.

Thanvi says, “With the help of smart sensing technology, real time monitoring of process performance, applications and analytics tool, we have offerings to support industry in their compliance and manage their operation risk while help them in comply or in some cases exceed regulatory requirements. At Schneider Electric, we provide complete solutions for businesses and help optimise machines (secure power, power quality, edge controls, instrumentation, RTUs, packaged ED) and also co-engineer their machines; we help them monitor their machines across various locations with asset performance solutions.”

Security of oil and gas infrastructureSafety in the oil and gas sector includes protecting the barrels and making the processes cyber safe. The scale of cyber-attacks continues to grow across industries around the world. Companies and their assets will be at increased risk of attack as the oil and gas cyber environment expands to include connected computing devices, personnel, equipment, infrastructure, applications, services, telecommunications systems, and the totality of transmitted and/or stored information. However, according to Bhatia, adopting a reliable IIoT solution can help reduce or negate the chances of cyber-attacks. He says, “Emerson’s cyber security services are designed to help identify vulnerabilities, close protection gaps, and secure the process control systems from cyber security risks before an attack threatens to impact the business. Emerson has recently inaugurated a global cyber security lab in Pune to help customers around the world address these concerns.”

Safety and precautionary measures in the oil and gas sector

Safety and health management is one of the vital constituents of oil and gas industry because most of the operational conditions, chemicals and end products (hydrocarbons and other compounds) associated with oil and gas production pose serious safety and health threats to the workers and the environment they live in. This can be done by adopting safety monitoring programs that include active monitoring far outclasses, manual check-in processes and spot-checks that can significantly improve an organisation’s ability to respond to safety incidents at any time and moment.

Thanvi suggests, “By using Schneider Electric’s EcoStruxure Power & Process, one can keep the employees and assets safe by reducing environmental risks and improving incident prevention. This IIoT enabled architecture transforms your plant to be safer for your people, production and profits.”

Job opportunities in O&G sector

Considered the biggest sector in the world in terms of dollar value, the oil and gas sector is a global powerhouse that employs hundreds of thousands of workers worldwide and generates billions of dollars globally each year.In India, the oil and gas sector plays a major role in influencing decision making for all the other key segments of the economy. So. According to Thanvi, “This is driving a renewed focus on operational excellence within oil and gas operators.” In India there is an acute shortage of skilled workforce in the oil and gas industries. This shortage is due to the lack of awareness about opportunities in these fields and due to extreme working conditions especially in the upstream segment, people remain aloof from this sector.

However, Bhatia says, “Job opportunities in the oil and gas sector will only trend upwards. However, he says, “The nature and qualification or skill requirement would shift towards Big Data and analytics, IT application platforms, operations, infrastructure and cyber security as compared to offshore and on shore site jobs.” Companies in the O&G sector need to initiate re-skilling programs for their employees now, in order to ensure they are truly ready for the onset of the technological take over in the near future.

Safety in the oil and gas sector includes protecting the barrels and making the processes cyber safe.

Anil Bhatia, Vice President and Managing Director, Emerson Automation Solutions – India

Safety monitoring programscan significantly improve an organisation’s ability to respond to safety incidents at any time and moment

Niraj Thanvi, Director, O&G Segment, Schneider Electric-India.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.