A transition curve in ev making

By OEM Update Editorial January 31, 2024 6:43 pm IST

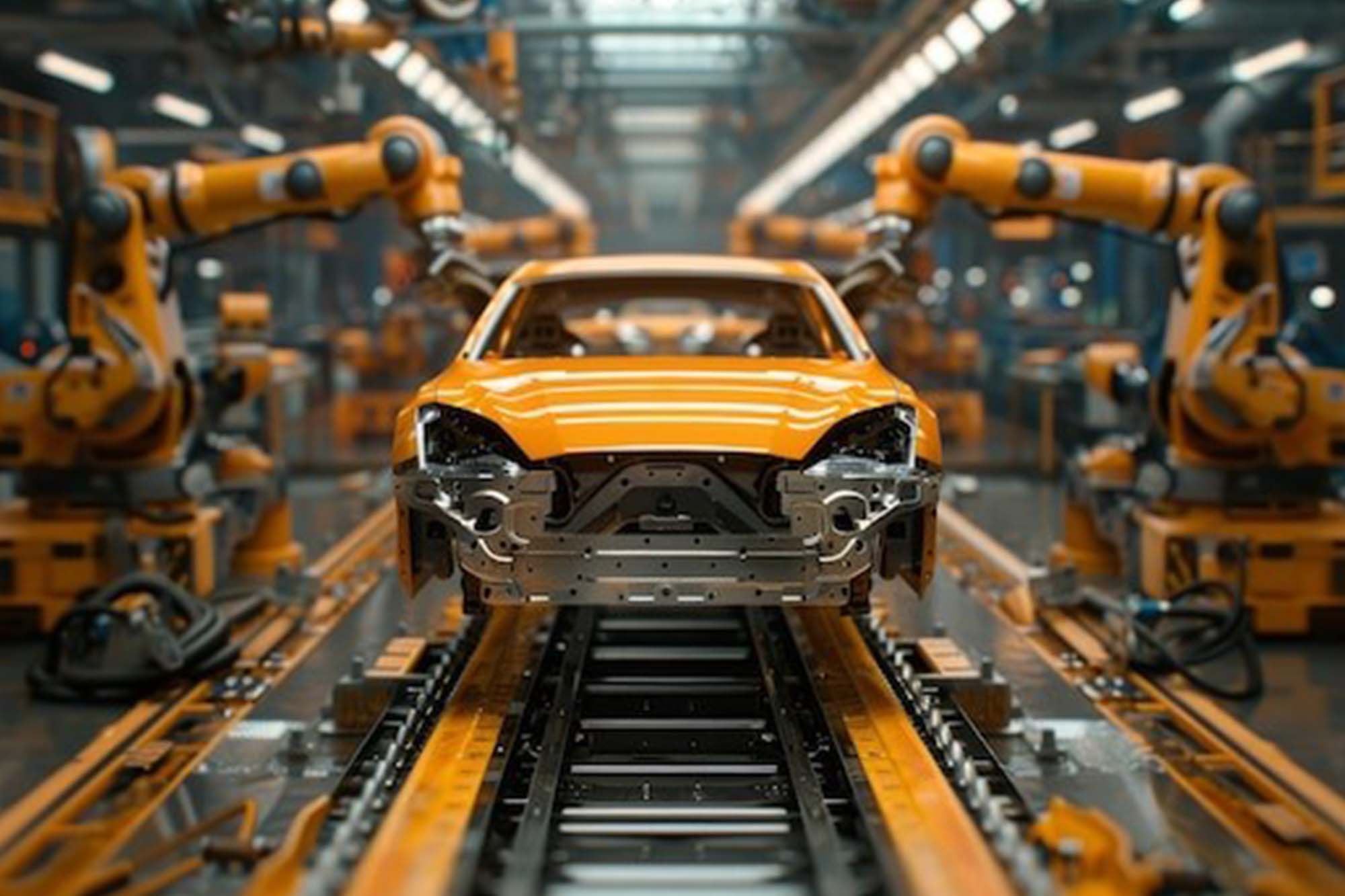

With the rising manufacturing industry and the automotive sector playing a significant role, India stands poised to assert its global dominance. As the EV industry experiences rapid growth and transition, India emerges as a major manufacturer and consumer of electric vehicles. With a focus on ‘Made in India’ for domestic and international markets, industry experts delve into the discussion surrounding the transition of manufacturing for EVs.

The automotive sector will play a major role in the shift towards sustainable energy. The Indian electric vehicles (EV) market is projected to grow significantly, with an expected annual sales of one crore units by 2030, as per the Economic Survey of India 2023. This growth is estimated to generate approximately five crore direct and indirect employment opportunities. The government has implemented various initiatives to support this development.

India became the third-largest automobile market globally, surpassing Japan and Germany in terms of sales in December 2022. In 2023, the total sales of EVs reached 1.53 million units, showing a significant increase from 1.02 million units in 2022. The automotive sector is a significant contributor to the GDP, accounting for 7.1% of the overall GDP and 49% of the manufacturing GDP.

Mobility scene for 2024

Initially, conversations revolved around understanding EVs, but today, the focus has shifted to why businesses still need to be in the EV space. Maxson Lewis, Managing Director & CEO of Magenta Power Pvt. Ltd, says, “I am very optimistic about the trajectory of EV adoption. However, we must carefully analyse the various use cases, whether for two-wheelers, three-wheelers, four-wheelers, or buses. Remarkably, certain segments, like electric three-wheelers, are experiencing unprecedented growth, surpassing sales of traditional ICE engine three-wheelers over the past four years.

This bullish trend is expected to continue, particularly over the next three years (2024-2026), marking a significant surge in EV adoption. Many lingering questions regarding EV adoption have been answered, and the focus now shifts to optimising models and scaling up operations rapidly.

Adaptations

Dinesh Arjun, CEO and Cofounder, Raptee, adds, “There is a growing realisation that transitioning to EVs is not solely about sustainability or achieving better total cost of ownership. It is viewed as a natural progression, akin to moving from steam to gas engines. EVs offer easier driving experiences and, in some cases, are safer than their internal combustion engine counterparts. This understanding is crucial for facilitating widespread adoption, as relying solely on subsidies and external factors can only do so much to drive the transition. True change occurs when individuals organically embrace the idea of EVs, a trend that has become increasingly apparent in recent months or years.”

Designing approach

Two notable developments are occurring. Previously, materials used in ICE vehicles were repurposed for EVs without ground-up engineering, as noted by Maxon Lewis. The transition now is happening towards designing new vehicles specifically for EVs. This eliminates concerns like vibration management inherent in ICE vehicles. This ground-up design approach, evident in two-wheelers, three-wheelers, and four-wheelers, incorporates composite and lightweight materials to reduce weight and redistribute it away from the engine bay to accommodate battery banks.

Thermal runaway challenges do not stem from the batteries but from the battery management system (BMS). Many BMS systems used to be re-engineered from elsewhere and were not cell-specific, as cells were sourced separately and packed before being adapted to the BMS. However, all new vehicles we observe from the OEMs now feature BMS systems tailored to Indian conditions, considering the country’s higher ambient temperatures. This shift reflects remarkable advancements in BMS design specific to India.

Cost efficiency

In the machining sector, changes are driven by evolving demands within the automotive industry. While lightweight materials have been a major focus, this aspect is less critical in the current electric mobility landscape due to the batteries’ substantial weight. Peter Auerbeck, Key Account Manager E-Mobility, Grob Werke GmbH & Co KG adds, “Prioritising cost efficiency is crucial, as reducing costs for electric vehicles remains a key challenge for the automotive industry to attract customers in lower price segments. Rather than focusing solely on lightweight materials, our optimisation efforts are centred around reducing the number of parts influenced by innovations like Tesla’s Giga casting. This entails a shift away from traditional body and manufacturing lines towards increased use of casted and extruded parts, reflecting a broader rethinking of car production methods.”

Supply chain

For mass production, particularly products manufactured in large quantities such as hundreds of thousands or even millions of units, unit economics is paramount for OEMs and all players in the supply chain. Even a small cost reduction, such as shaving off half a dollar, can significantly impact. The challenge, however, lies in the uncertainty surrounding the cost of raw materials, as seen with fluctuations in aluminium prices in recent years. While stability has since been achieved to some extent, this unpredictability makes it difficult for OEMs to experiment with new-age metals in production.

Tesla’s use of cells as structural components showcases the risks that innovative OEMs like them can take, though the long-term outcomes of such decisions remain to be seen. Instances like the Giga press, while effective, pose challenges in terms of cost and repairability if issues arise. More established OEMs may have the flexibility to take calculated risks in innovation. In contrast, the budding ones face limitations due to the nature of mass manufacturing and the constraints of working with new materials.

Entrepreneurship

Over the past four to five years, there has been a noticeable shift towards entrepreneurship and increased manufacturing activity. The primary motivation behind this surge in interest is the availability of raw materials in India at competitive prices compared to China, which has historically been the benchmark for pricing discussions. Efforts from the Indian central government and relevant ministries are focused on ensuring competitive costs for raw materials within the country, fostering a conducive environment for manufacturing to thrive.

Tyag Dharmik, Director, Chhabi Electricals adds, “Our efforts in manufacturing EV chargers in India involve sourcing 75% of components locally, with only the power module still being imported from China, a common practice among major EV charger manufacturers. Addressing this dependency on imported components, particularly for power modules and CCS two guns, presents a significant opportunity for India to establish itself as a manufacturing hub. By leveraging local manufacturing capabilities and reducing reliance on imports, we can enhance product quality, create more employment opportunities, and contribute to the overall growth of the manufacturing sector in India.”

Industry consolidation

Government statistics from two years ago indicated the presence of approximately 352 so-called two-wheeler manufacturers in India, with most being assemblers rather than actual manufacturers. Many of these units sourced vehicles and components from abroad, even though they sported a “Made in India” sticker.

However, there has been significant consolidation in the industry since then. According to the latest figures from the registered E-Amrit portal, there are now around 380 OEMs across India. Approximately 40 are dedicated to two-wheelers, 80 to three-wheelers, and 20 to four-wheelers. This trend towards consolidation is notable as it enables manufacturers to benefit from economies of scale and invest more in research and development.Maxon Lewis shared that previously, the focus was on component-level inputs, but now the emphasis has shifted to sub-component-level inputs. While it is acknowledged that not everything can be manufactured in India, there’s significant R&D activity happening in the country, leading to value addition at the sub-component level. There is a notable increase in investments in manufacturing within the EV industry, with Mahindra being a prominent example.

There is a tendency to focus solely on the OEM level in manufacturing discussions, overlooking the ancillary industry’s significant impact. Traditional auto ancillary suppliers, initially catering to internal combustion engine (ICE) vehicles, are adapting their production systems to accommodate electric vehicles (EVs), highlighting the importance of recognising this transition.

Local production

The trend for local production is fueled by concerns about potential trade conflicts between America and China, leading to increased localisation efforts to mitigate risks associated with international production. Over recent years, OEMs have prioritised localising their production processes and goods, particularly in the Asia-Pacific region, where projects in China are now predominantly focused on meeting local rather than global demands. This shift towards localised production signifies an expected increase in manufacturing activity in countries like India.

Another significant challenge for smaller companies is the complexity of designing and manufacturing battery modules and packs. Unlike traditional combustion engines, battery production involves numerous intricate process steps, often requiring substantial investments in automation. Companies must achieve high production volumes to reduce costs per unit and compete with Chinese manufacturers to remain competitive. This has led to a growing trend of smaller companies collaborating to increase production volumes and reduce costs.

Government policies

There is significant support from both the central and state governments for manufacturing initiatives. Citing an instance, Dinesh adds, “Our company, Raptee, has received manufacturing incentives and tax benefits since its establishment, indicating strong government backing. This support is prevalent across India, particularly in light of the growing emphasis on manufacturing, especially in the EV sector, following the “China plus one” sentiment. We recently established our manufacturing plant in the EV sector, marking nine years in the automotive manufacturing industry. Setting up a large factory, including regulatory compliance, has been remarkably smooth.”

The emphasis is not solely on manufacturing; merely importing subcomponents for assembly without adding substantial domestic value does not align with sensible practices. Policies like FAME have ensured that manufacturing efforts involve genuine value addition rather than just assembly. While there have been instances of exploitation and ongoing adjustments to address loopholes, these policies represent significant steps towards promoting indigenous R&D and manufacturing capabilities in India.

This focus on domestic value addition includes the adoption of foreign technologies along with colouring the importance of integrating substantial domestic value into manufacturing processes. This principle has been clearly emphasised.

======================

Quotes

Dinesh Arjun, CEO and Cofounder, Raptee

“For mass production, particularly products manufactured in large quantities such as hundreds of thousands or even millions of units, unit economics are paramount for OEMs and all players in the supply chain. Even a small cost reduction, such as shaving off half a dollar, can significantly impact.”

Peter Auerbeck, Key Account Manager E-Mobility, Grob Werke GmbH & Co KG

“To remain competitive, companies must achieve high production volumes to reduce costs per unit and compete with foreign manufacturers.”

Tyag Dharmik, Director, Chhabi Electricals

“Addressing this dependency on imported components, particularly for power modules and CCS two guns, presents a significant opportunity for India to establish itself as a manufacturing hub.”

Mr. Maxson Lewis, Managing Director & CEO, Magenta Power Pvt. Ltd.

“Traditional auto ancillary suppliers, originally catering to internal combustion engine (ICE) vehicles, are adapting their production systems to accommodate electric vehicles (EVs), highlighting the importance of recognising this transition.”

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.