Modernising Indian Industries with Industry 5.0

By OEM Update Editorial June 9, 2021 5:23 pm IST

Leaders from the manufacturing, sheet metal, and measurement industries share their perspectives on the effects of newer technologies on their businesses. They are also concerned about maintaining the safety of manpower and technology.

Industries embracing Industry 5.0

Industry 5.0, like any other growth model, currently has two visions of its future. The first vision depicts a workplace in which humans and cobots collaborate in a seamless manner, with humans focused on creativity while cobots do the mundane tasks of the shop floor.

However, the second vision sees it evolving as a bio-economy-based industry in which all-natural resources are used wisely and efficiently, and are continually recycled to achieve a balance between ecology, industry, and economy.

Our acceptance for Industry 4.0

Explaining the advantages of industry 5.0 to the electronics and instrumentation industry, Sriram Ramakrishnan, Managing Director, Fuji Electric India Pvt. Ltd says “With the Government’s push for AtmaNirbharBharat and ‘Make in India”, there is a big focus on manufacturing sector’s growth becoming important for prosperity of India. While focus of the government is on increasing employment, across industries it has become very clear that to compete in the global market Indian industries have to manufacture more efficiently with good quality and at a competitive cost. This is forcing many Indian industries to embrace the increasing use of Automation in their factories.”

Niraj Seth, President, Amada India, prefers to share his views on the impacts on Sheet Metal Forming Industry. According to him, the industry was recovering post COVID till Jan 2021; then the sudden upsurge in the number of cases and subsequent lockdown has again put the entire industry on back foot. “The sheet metal industry has suffered in a big way. Blanket ban on supply of oxygen to industry has impacted Sheet Metal manufacturing to a great extent. Fibre-laser cutting machines are one of the key machines in fabricating the sheet metal components which require O2 as assist gas. This has really hampered the fabrication work.”

Whereas, giving an overview from the plate cutting and laser cutting sector provider, Utkarsh Landekar, Head – Laser Business (India & Exports), Messer Cutting Systems Pvt. Ltd., feels that presently, the sheet metal and plate cutting industry is undergoing a radical change in the process due to the introduction of Laser and Plasma systems to cut the same. “There is a rapid rise in Laser sales due to falling prices and higher production of machine quantities. Moreover, technologies like Laser edge machining; Ultra Jump, Zip cut and Scan cut has been introduced. As a result, lasers are replacing many traditional processes such as edge machining, milling, drilling, punching, and shearing. There is a shift in the thought process.”

According to Niranjan Manjrekar, GM – Operations, LVD India, “In every difficult scenario, you have to be best equipped with options and possibilities. This Pandemic has tested it again. The present market seems to be more thoughtful and systematic in its activities, investment and also optimising operating costs.

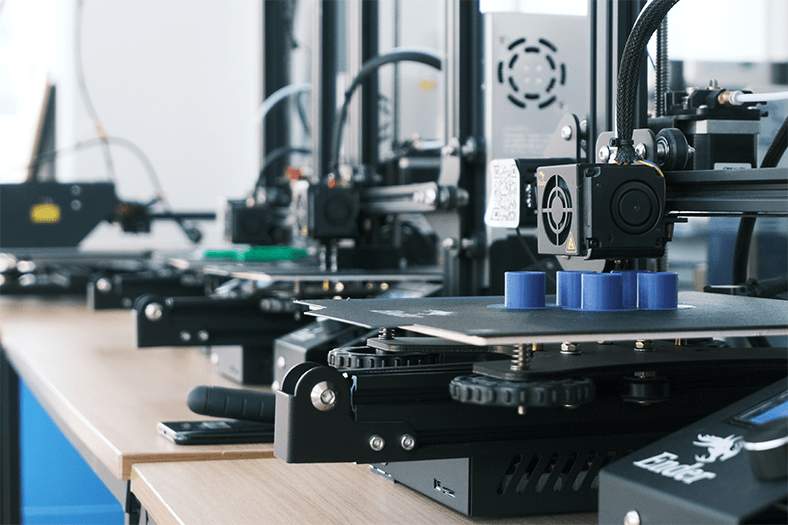

Nitin Chaudhari, Partner, Sree Rapid Technologies Pvt. Ltd. says, “India is showing significant growth in Manufacturing. With ‘Make in India’ which also is leading to design/innovate in India, I am absolutely certain that the coming years are going to be watershed years for the manufacturing industry. 3D printing / additive manufacturing being the most sought after I am expecting hyper growth as well as adoption across the board.”

Enhancing industries processes with automation

Fuji Electric is also globally renowned for its products, which are used to measure energy, power, pressure, temperature and flows which are the key physical parameters to be measured based on which devices can be controlled to optimise the overall performance of a machine, process or factory. “In smart factories, PLCs are positioned as edge controllers to collect time-series data from machines and sensors (field devices) in the field,” says Sriram.

Here, Utkarsh highlights key points. He explains that the main technologies are precision control systems, well-engineered dynamics of the machine, the latest design software and state of art futuristic software to cater to IoT, Industry 4.0 and 5.0.

Anudeep Garg, Plant Manager –Automotive Brake Systems, Autonomous Mobility and Safety (AMS), Continental Automotive India, With Industry 5.0, we are looking at a future where robots will do mundane, repetitive tasks while humans handle the creative aspects. With a higher degree of personalisation required in some sectors and products, Industry 5.0 will become necessary. It is not about a matter of adoption, but of growth – where we find the right balance.

P L Muthusekkar, Managing Director, NORD DriveSystems Pvt. Ltd., Along with Industry 4.0 the Industrial Internet of Things (IIoT) focuses on internet usage in industrial processes and procedures. IIoT aims at increasing the operational efficiency, reducing costs, and speeding up processes. Sensors and sensor data playing a central role provide the basis for condition monitoring and predictive maintenance. When it comes to predictive maintenance – the objective is to maintain machines and plants proactively, to reduce downtimes and to increase the efficiency of the entire plant.

Niraj. He further adds, with our tailored automation, customers can significantly enhance their bottom line by combining high-speed, energy-saving technology (Fibre Laser and Servo controlled machinery).Highlighting the significance of Laser cutting tools and technologies, Niranjan says that the laser cutting has now been in the market for quite a while and has evolved dynamically. Year on year, new lasers added to the market are expected to grow by 17 – 20 percent. “Having said so, CAD/CAM is the only medium by which the user can be more equipped to get the best output of the Laser machines at an optimised ownership cost. This tool has been extremely helpful in defining the overall efficiency of the machine as well as predicting the load factor, which can aid in making realistic projections for future business.”

Challenges in adopting path-breaking technologies for SME and MSME

According to Muthusekkar, Cash Flow – Payment delays, selling on cost etc, Outdated Technology – Lack of capital / Lack of Infrastructure – Skilled Manpower are some of the major barriers in adopting automation, continuing with their old business practices and technologies. Usually one-man decisions, no broad consensus, where and how to start etc. are the main challenges for SME+MSME.

According to Anudeep, while the benefits are plenty, this change is effort-intensive and capital intense. There is no one-size-fits-all strategy. The scale, pace, and levels of automation are different across organisations. “However, smart factories with modern technologies are going to be cost and time-effective. They will transform the industrial processes and improve efficiency, productivity, costs, value to customers, among other benefits.”

According to Niranjan, “The major need is to know the right capacity of the infrastructure (Man, Machines) and to optimise efficiency. The key to this is to have a tool that can effectively manage this parameter, and factory management software will do just that.”

Whereas, Utkarsh highlights that there has been an inflow of cheap imported and few locally manufactured machines which buyers find irresistible to buy. “They are built with a lot of compromises to the operator’s safety. This is primarily due to lack of awareness of Laser safety guidelines. We educate our clients and also produce machines which comply with global laser standards. With Messer Laser there is no compromise on safety.”

“Despite financial limitations, many SMEs are eager to upgrade to new technologies. Though there are many low-cost automation products available, integrating them into a cost-effective solution which delivers the intended results remains a challenge without the right System Integrator partner,” says Sriram.

Latest Technologies

Amada has also developed a high-brightness fibre laser oscillator to maintain the high-energy density laser beams optimal quality. LBC Technology combined with a high-brightness oscillator set a new world standard for fibre laser cutting speed and quality.

Messer’s latest offering are covering the most of laser machines required in the industries. They are in 2 categories Pre-cut sheet metal systems and large plate cutting systems. In the first categories machine like 3X1.5,2X4,2X6.3,2X8 which are the Indian standard cut plates are catered using standard format laser machines (SFLM).

The Way Forward

Talking about the automotive industry, Anudeep says “Industry 5.0 is a natural transition in manufacturing progression. We have to also bear in mind that wide-scale adoption of Industry 4.0 practices has still not trickled down to grass root level the way it is expected to be, which means a lot of efforts needed here in terms of investment, operational implementation, skilling, and upskilling, etc”. Only once we have a platform laid out for connected ecosystem, automation, and digitisation, the transition to Industry 5.0 will be much easier. No doubt Industry 5.0 is the future and we are getting there, we have the right kind of awareness and India will reap immense benefits from Industry 5.0.

Whereas, Muthusekkar says, we at NORD DRIVESYSTEMS, we are focused more on communication, trainings, use of online tools, Digital Marketing, conducting Surveys. Of one all care of our employees, customers, supply chain and kept the industry moving particularly essential support to Pharma, Diary, Food and Beverage, Vaccine Producers etc.

There has been a significant shift in the manufacturing industry from traditional to smart manufacturing, compared to 2014 more start-ups have become keen on making use of the advanced technologies for newer product developments & end-use product manufacturing. “Keeping in mind the shift of manufacturing industry, from resin/polymer systems to wax to metal including large frame metal printing using robotic integration to technical ceramics, we are offering industry leading solutions all under one-fold with a dedicated application focused consultation as well as implementation,” Nitin conclude.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.