Manufacturing excellence with a well-designed panel

By Staff Report August 9, 2024 6:04 pm IST

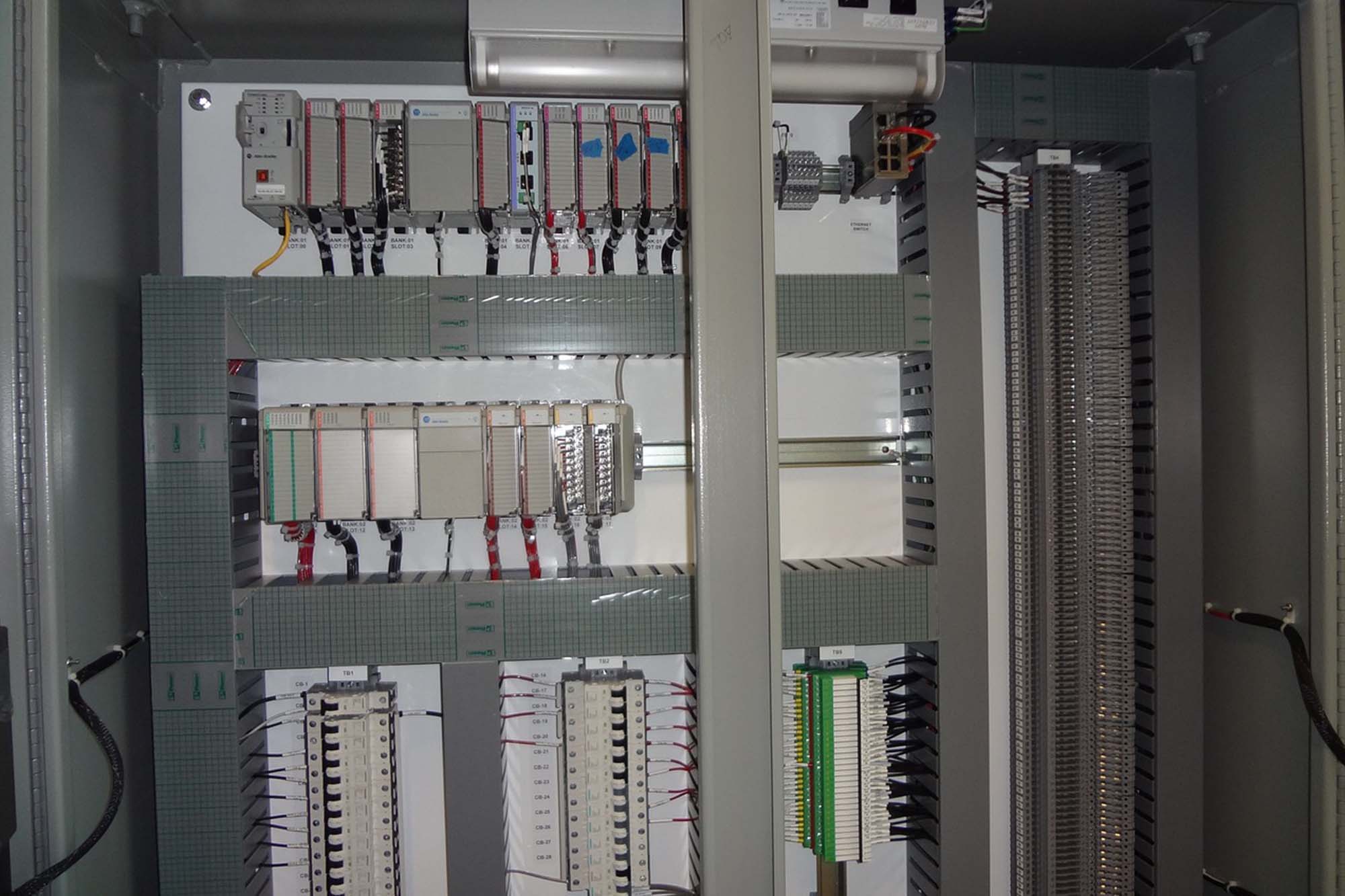

A well-designed industrial control panel is the backbone of modern manufacturing and industrial processes, ensuring machinery and systems’ safe, reliable, and efficient operation. Mark Inboden, President of Utility Control and Equipment Corporation, emphasises the importance of industrial control panels in manufacturing processes.

Industrial control panels are keys for the efficient and safe operation of manufacturing processes. These panels serve as the nerve centres for various machinery and systems, ensuring proper functioning while safeguarding personnel and equipment. A well-designed industrial control panel is essential for smooth operations and minimising downtime.

The features of a well-designed industrial control panel

Compliance with Regulatory StandardsUnderwriters Laboratories (UL) and the National Electrical Code (NEC) supervise the development and installation of control panels in the United States; the International Electrotechnical Commission (IEC) regulates the same in Europe. Compliance provides safety, dependability, and legality. It includes adhering to guidelines for wire sizing, insulation, component selection, and protection against electrical faults.

The robust enclosure design component protects against environmental variables such as dust, moisture, and physical damage. It is adapted to the application’s requirements, whether indoors, outdoors, or hazardous. Enclosures must be sealed, adequately ventilated, and equipped with cooling systems. Ingress protection ratings (IP, NEMA, and UL Type) determine the level of protection against solid objects and liquids.

Selecting the right components improves the control panel’s performance and longevity. These components include circuit breakers, relays, terminal blocks, contactors, and more. It is vital to choose reliable, quality components from reputable manufacturers. The panel should be organised intuitively, with logical wiring schemes and clear labelling for easy maintenance, troubleshooting, and future expansions.

Effective cable management is a hallmark of a well-designed control panel. All wiring must be neatly organised, and colour-coded wires and proper cable labelling help to identify and trace connections. Wiring should adhere to best practices, minimise cross-overs, and be cautious of potential electromagnetic interference (EMI) and radio-frequency interference (RFI). Conduit and cable trays are for protection and organisation.Safety is paramount when dealing with industrial control panels. Panels with proper design features like emergency stop buttons, interlock mechanisms, and safety relays are crucial for ensuring the safety of personnel working with or around equipment. Overcurrent and short-circuit protection devices like fuses and circuit breakers prevent electrical fires and equipment damage. Thorough grounding and bonding also prevent electrical hazards.

The control system is an essential component of an industrial control panel, providing precise control over machinery or processes. It is a human-machine interface (HMI), and modern control panels often incorporate programmable logic controllers (PLCs) or microcontrollers for advanced automation, monitoring, and data logging.

A well-documented control panel is easier to understand, troubleshoot, and maintain. It requires comprehensive documentation such as wiring diagrams, component lists, panel layouts, and operational manuals, along with planned maintenance schedules, spare parts lists, and safe panel access and service.

Conclusion

Properly designed industrial control panels are the backbone of modern manufacturing and industrial processes. They ensure safe, reliable, and efficient machinery and system operation. Compliance with regulatory standards, robust enclosure design, component selection, wiring and conduit management, safety features, a well-designed control and monitoring system, and comprehensive documentation are the most critical features of a well-executed control panel. By paying careful attention to these aspects, industries can minimise downtime, reduce the risk of accidents, and improve productivity.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.