Let’s adopt eco-friendly manufacturing practices for sustainable growth

By OEM Update Editorial December 29, 2023 7:32 pm IST

Kabir Bhogilal, Executive Director at Batliboi, shares perspectives on India’s manufacturing outlook, digital integration, sustainability, CAD/CAM advancements, and eco-friendly practices driving the industry growth.

Please share your views about the country’s manufacturing outlook for 2024.

The manufacturing sector in 2024 is expected to experience robust growth, driven by increased investments in technology and infrastructure. There is an expected increase in cutting-edge manufacturing technologies like robotics and automation, aiming to improve productivity, quality, and cost-efficiency. The optimistic outlook relies on favourable governmental policies and a focus on developing local manufacturing capabilities.

Also, expos like ENGIMACH are poised to accelerate economic expansion substantially. By spotlighting cutting-edge technologies and innovations within the machine tool sector, the events act as a central point for networking, sharing expertise, and nurturing partnerships. Its influence is pivotal in generating new business opportunities and driving the progression of the manufacturing industry in the times ahead.

How do you see incorporating digital technologies and robotics contributing to enhancing efficiency within CNC machines?

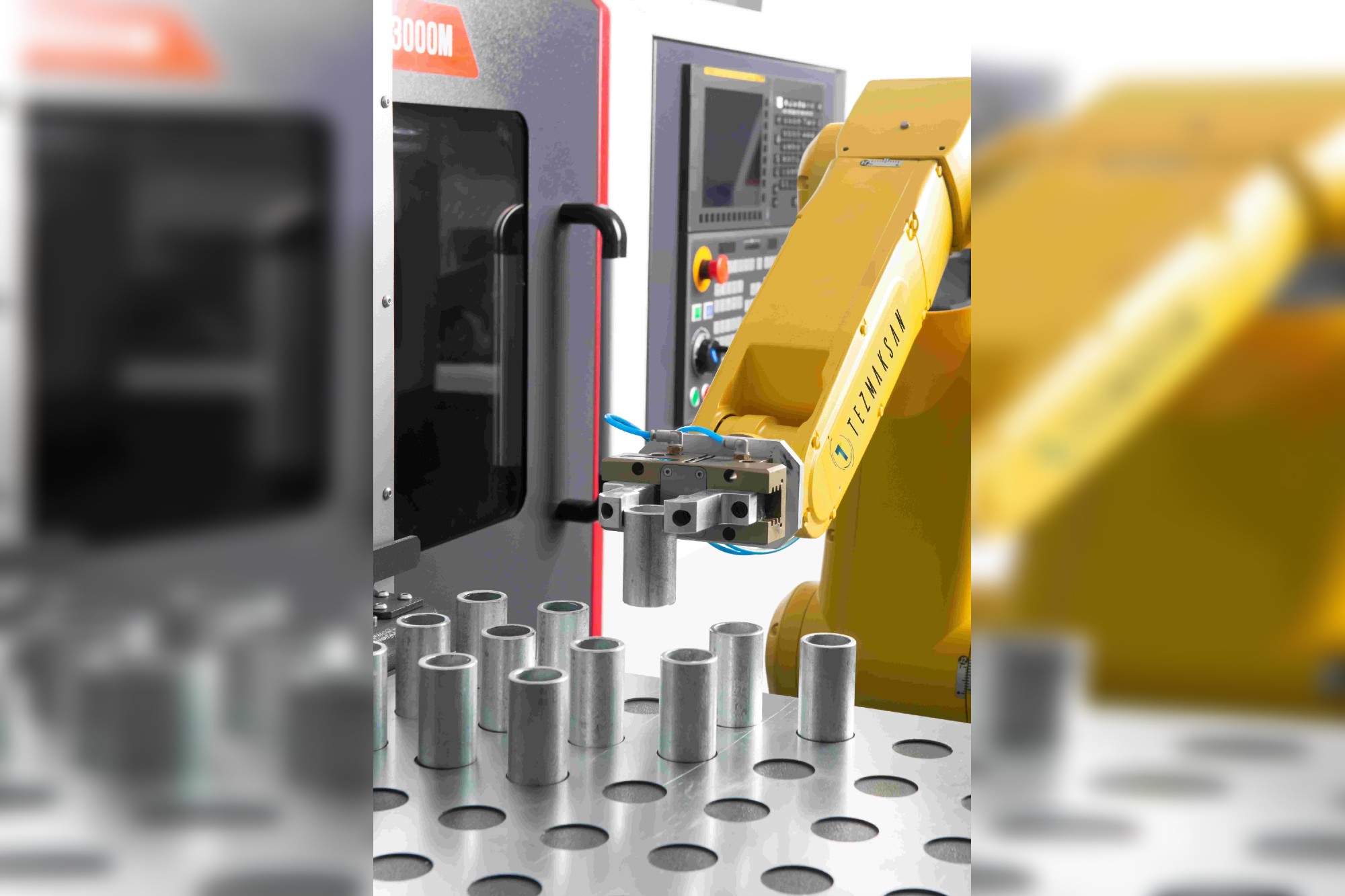

Integrating digital technologies, Industry 4.0, and robotics within CNC machines is revolutionising manufacturing. This transformation enhances efficiency, accuracy, and adaptability, enabling the execution of intricate and precise tasks with minimal human involvement. This integration is essential to competitiveness in a rapidly evolving global industry landscape.

In what ways do you anticipate Make-in-India and Atmanirbharta propelling growth within India’s manufacturing sector?

The Make-in-India initiative and the push for Atmanirbharta drive growth in India’s manufacturing sector. By focusing on domestic manufacturing and reducing dependence on imports, these initiatives foster an ecosystem that encourages innovation, quality improvement, and cost competitiveness.

Government and industry bodies advocate for digital manufacturing as a pivotal element for sustainable development. Through incentivising the adoption of digital tools and methodologies, they support manufacturers in curbing waste, enhancing resource efficiency, and minimising environmental impact. Embracing sustainable materials and technologies to diminish our carbon footprint is imperative for sustained advancement in the industry.

Please talk about the recent progressions in CAD/CAM software tools tailored to fulfil diverse needs in CNC programming.

The latest developments in CAD/CAM software have transformed CNC programming significantly. These innovations encompass better multi-axis and multi-channel programming functions, upgraded simulation abilities, and the generation of more effective toolpaths. These improvements enable more precise and efficient machining, ultimately cutting down on cycle time, programming and setup duration.

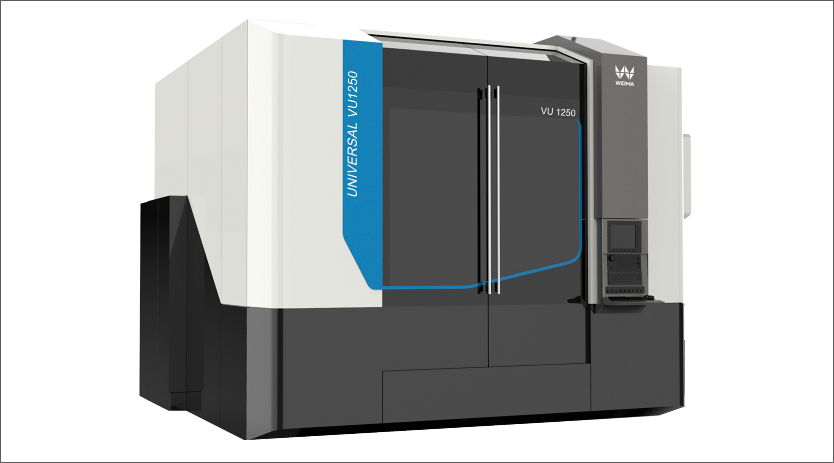

What are the most recent advancements in the manufacturing of CNC milling and drilling machines and lathes?

The latest developments in CNC milling and drilling machines targeted at the electronics industry, such as High-speed Drill-tap centres, as well as automated lathes employing Gantry loaders, machine-tending robots, and multi-spindle, multi-turret machines, have substantially increased the production speed for precision parts. Newer models are more energy-efficient, offer better control, and are equipped with advanced sensors for real-time monitoring. The feedback of critical process parameters is enabling the industry to take on the competition in the global market.

How do you perceive the incorporation of environmentally friendly practices in the manufacturing sector?

Integrating eco-friendly practices in the manufacturing sector is not just a trend but a necessity. It is crucial for sustainable growth. Sustainable manufacturing processes, waste reduction, recycling, and renewable energy sources are becoming increasingly important. These practices help protect the environment and improve manufacturing operations’ overall efficiency and cost-effectiveness.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.