STUDER CNC universal cylindrical grinding machines take priority at SELSA

By OEM Update Editorial January 25, 2024 6:49 pm IST

For over 30 years, the Turkish company SELSA has supplied international automotive industry clients with high-quality components. It has significantly expanded its business field with five new STUDER cylindrical grinding machines.

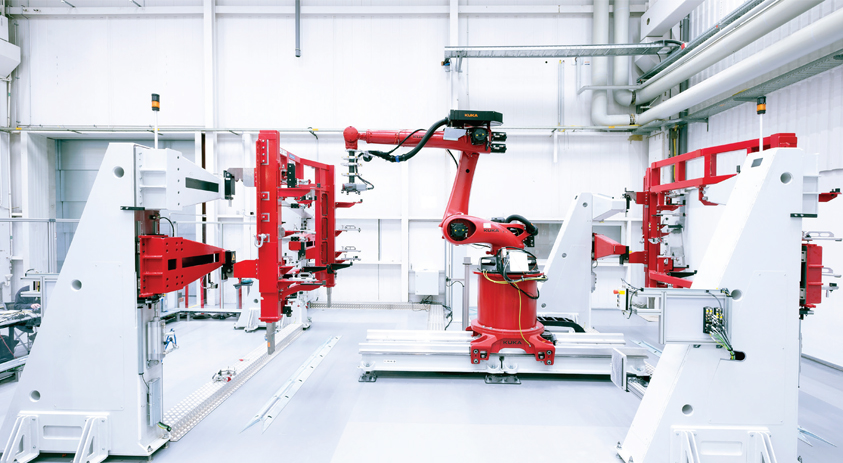

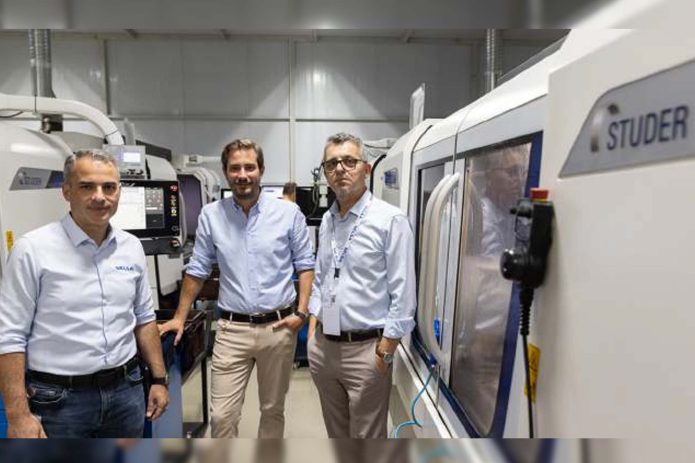

Five CNC universal cylindrical grinding machines from STUDER have been added to the operation. Speaking from his office at SELSA’s headquarters in Bursa in the northwest of Turkey, explaining the purchase of four favourite machines and one favourite CNC, Cem Dizdar, Managing Director of SELSA, says, “There is no more prestigious brand than STUDER when it comes to grinding machines, and we did not want to compromise on quality and precision with this investment.”

Background

Dizdar recounts how his family fled former Yugoslavia for Turkey during the war, a move that no one could have imagined would lead to them founding one of the country’s flagship companies in the machining sector. His father, a mechanical engineer trained in Germany, established the company in 1992 from scratch. Back then, only a handful of employees worked in a small space.

Today, around 280 skilled workers manufacture precision parts for an international clientele, particularly in the automotive sector, in a modern 7,000 sq. mtr. (75,400 sq. ft.) facility operating around the clock. Salsa HQ in Bursa City, located on the Sea of Marmara, with historical significance and a population in the millions, is about an hour and a half’s drive from Istanbul and is one of the country’s most important industrial centres, particularly for the automotive industry.

Dizdar has been familiar with all the company’s operations and processes since his youth and later studied mechanical engineering in Istanbul himself. When his father suddenly died in 2014, he had to take responsibility overnight. He says, “What my father, Selami Dizdar, built and accomplished fills me with pride and gratitude. We have an excellent team and a well-coordinated system.”

A German automotive supplier has operated in Bursa since the 1970s, holding significant historical ties for Dizdar. His family’s connection spans generations—his grandfather worked there, his father underwent additional training, and his German mother taught the children of the company’s employees while in Bursa. Nevertheless, it is quite natural for the younger generation to have a new perspective.

Evolutionary milestones and strategic focus at SELSA

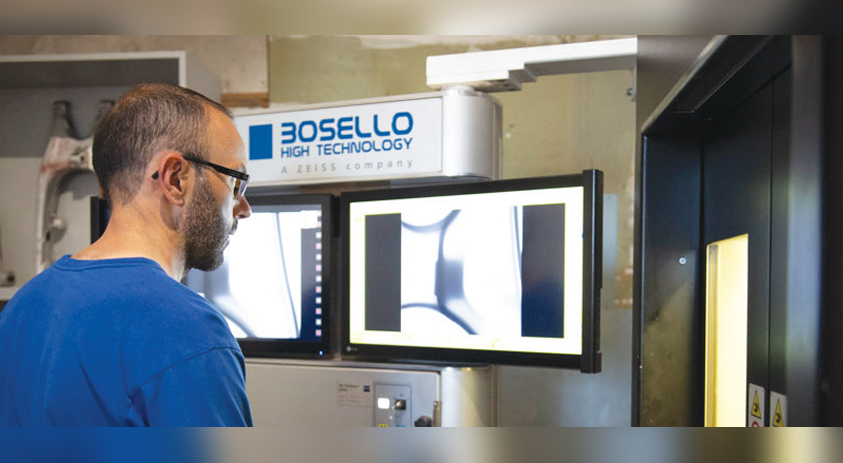

A significant milestone for SELSA was the first major order for the mass production of diesel injection nozzles in 1995. The high demands on quality, precision, and efficiency have become ingrained in the company’s DNA, earning it a reputation beyond the local region.

Innovative strength is essential today in the automotive sector undergoing rapid change. The switch to electric motors or stricter CO2 emission regulations are just two examples. For the managing director, diversifying the customer base and focusing on high technology is particularly important for the current strategic orientation of his company. SELSA currently invests around 4.7 percent of its total budget in research and development and is now recognised as a research-and-development facility for mechanical engineering by the Turkish state.

Strategic investment in Studer machines to meet demands

Acquiring the five CNC universal cylindrical grinding machines from STUDER is a strategic move. Dizdar explains that a significant new order from a top supplier of steering and transmission pumps prompted this investment. Specifically, the STUDER machines now produce around 700,000 drive shafts for control pumps yearly. He said, “We received the customer’s exact specifications and tight tolerances for complex geometries. The STUDER machines enable efficient mass production of technically demanding workpieces, and they have played a large part in our receiving this order and being able to fulfil it to the fullest satisfaction.”

Decision for 5 STUDER machines!

Atilla Aydin, area sales manager from STUDER for Turkey, who has advised SELSA personally and on-site from the beginning, in knew of the solution, said, “We closely examined the geometric requirements of the components and the desired production volume and had them checked by our in-house engineers and specialists.”The sophisticated grinding technology, high-quality components, and the thermally stable machine bed made of mineral cast Granitan® make possible simple operation with the Studer Pictogramming software: the STUDER favourite. It ensures high component precision and optimal operational processes. “It is suitable for universal use in both single and mass production, operates at high speed, and makes no compromises on quality and precision,” explains Aydin. The good cost-effectiveness of the favourite results in a unique value for money on the market.

Result: Competent consulting and collaboration

Dizdar says, “Atilla’s advice was top-notch, and we immediately felt comfortable. The outstanding customer service was a key reason we chose STUDER.” However, STUDER’s delivery, installation, and CE-certified commissioning of the machines are just the beginning.

With a 25-year tenure representing STUDER in Turkey, Aydin understands the local customer base’s expectations, which prioritise swift, personalised communication alongside exceptional expertise. He says, “We have worked closely with SELSA to optimise the production operations, and of course, our customer care and service experts are always available with their expertise to assist with any questions or issues.”

Ongoing discussions on process optimisation after the commissioning of the STUDER machines resulted in the establishment of a dedicated climate-controlled room to manage operating temperatures. Described as a miniature laboratory, this setup enables remarkable precision in grinding drive shafts, meeting their customer’s complete satisfaction. Dizdar expresses pride in this achievement. Additionally, the training imparted by STUDER to the staff significantly boosted both efficiency and quality, elevating them to new levels.

SELSA’s prospects in the automotive sector

Dizdar says, “I positively see our prospects for further business development in the automotive sector.” Turkey is highly attractive to international companies due to top-notch expertise and economical production conditions. Furthermore, launching the first Turkish electric car brand is just around the corner. He adds, “Our order situation is positive. Manufacturing highly technical components in large volumes with the machines gives us a clear competitive edge, and we look forward to continuing our journey with STUDER.”

For the Managing Director, Dizdar, business partnerships are more than just one-time transactions; he values long-term and trust-based relationships. He says, “It is great that we are on the same wavelength with STUDER.”

SELSA is a modern, international company where, besides Turkish, both German and English are spoken. Values such as quality assurance, occupational safety, and environmental protection are as much a part of the corporate culture as is the recognition of humanity, regardless of gender, religion, or ethnic background.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.