Orbital welding systems for high quality and enhanced productivity [Mar 2012]

By admin March 22, 2012 5:54 am IST

The power sector in India meets the energy requirement of the world’s 5th largest energy consumer, accounting for 4.0 per cent of global energy consumption by more than 17 per cent of global population. About 65.34 per cent of the electricity consumed in India is generated by thermal power plants, 21.53 per cent by hydroelectric power plants, 2.70 cent by nuclear power plants and rest being hydro, solar, wind and biomass power plants.

Rapid economic growth has created a growing need for dependable and reliable supply of electricity. Government of India has planned to enhance gross domestic product (GDP) to 10 per cent in 11th Five year Plan. In order to achieve this, energy requirement, which is one of the major contributing factor in upgrading the GDP, will increase. The country’s existing production & consumption of electricity is 181.5 GW and expected demand by 2020 is 950 GW.

Since thermal power plants produces majority of the electricity in India, the need for parts like deaerator, heat exchangers, super critical heaters, economizers, condenser, feed water heater are ever increasing. Welding is one of the major activities for tubes and pipes required for these components as well as for nuclear and other power plants. The future power plants will be super critical and ultra super critical for higher efficiency. The need for quality piping and tubing that can withstand higher pressures and temperatures is ever increasing.

Tubes and pipes are also used in the oil and gas industry as well as in semiconductor, pulp & paper, food processing, pharmaceutical and aerospace and other industries.

The intent of this article is to give glimpse of various welding techniques used in tubing and piping applications. This article highlights the concept and advantages of orbital welding and various weld heads used in different applications.

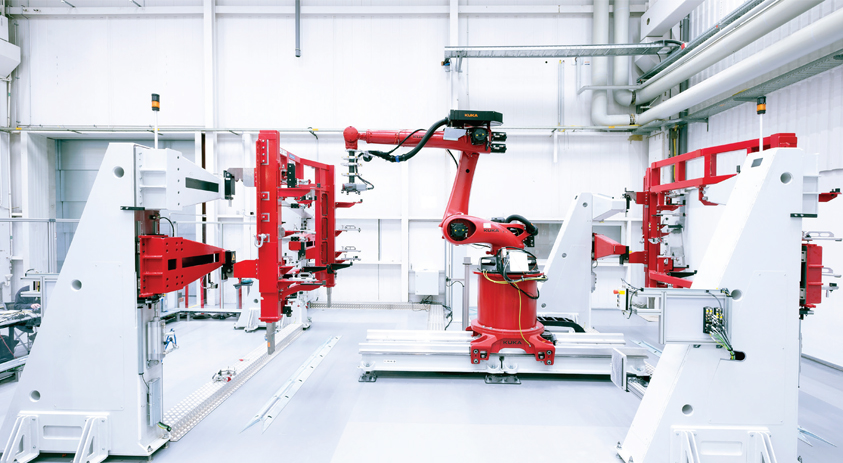

Traditional welding of pipes and tubes One of the oldest methods of doing welding in piping and tubing is manual metal arc welding and manual TIG welding; in the latter the operator welds the job by holding the torch in one hand and filler material in another. Though manual welding is one of the preferred ways of doing welding it has limitations like: • Weld quality throughout all joints is not consistently same• No control on joint to joint penetration and HAZ uniformity• Inconsistent torch travel speed and filler wire feed speed• Difficulties in all position welding – high skill of welder required• No uniformity in weld bead formation in case of grooved pipe welding • No oscillation & side wall fusion control over multiple joints• Low arc on time & frequent stoppages & starts.Orbital TIG welding concept To overcome these limitations the concept of orbital welding system was introduced and is now becoming increasingly popular in India as well. Orbital welding is a specialised area of welding whereby the arc travels circumferentially around the static work piece, in a continuous process without interruption.

In this mechanism the arc generated from the tungsten electrode rotates along the circumference of tube or pipe. The tungsten electrode is fixed on the rotor which is rotated by servo motor mechanism. This servo motor has a feedback encoder which detects the exact location of the electrode and controls the travel motion. These orbital welding power sources are either microprocessor or computer based programmable pulse TIG DC welding machines.

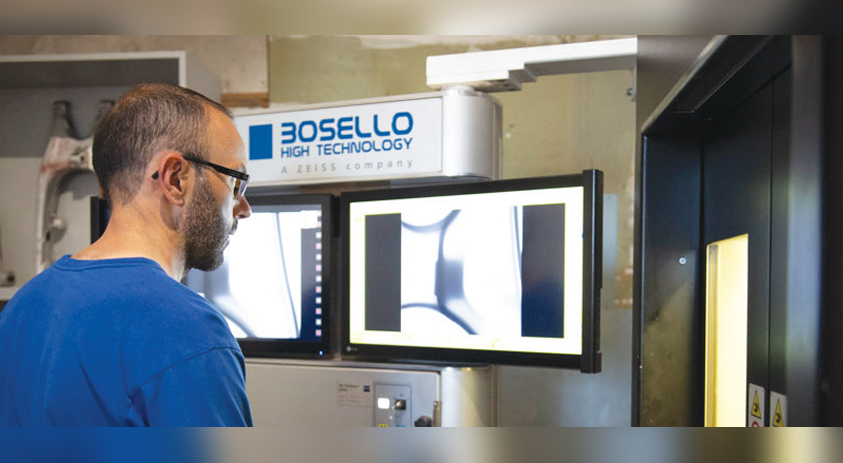

Advantages of using orbital welding Programmable power source: The power sources are programmable. They can store many programs for weld schedules with multiple levels. The print out of weld programs can be taken any number of times for ease of traceability. The display boards of power source are user friendly with simple Graphical User interface (GUI).

Better penetration and less HAZ: Being pulsed, TIG welding machines the heat input that is controlled over a period of defined pulse width with the help of primary and background current settings. This fulfils the basic objectives of better penetration yet lower HAZ.

Better quality & repeatability: The quality of first weld and last weld after several years will be identical with the proper weld schedule.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.