New motor technology brings lower energy, maintenance and noise to extruder

By admin May 12, 2016 3:01 pm IST

Constant torque application benefits from synchronous reluctance motor technology

Up to 15 per cent lower energy use, a significant reduction in motor maintenance costs and a drop in audible noise are achieved with the installation of an ABB synchronous reluctance motor and drive (SynRM) packages on a twin extruder application.

Radius Systems’ plant in Derbyshire, UK, houses 14 extrusion lines, each of which produces polyethylene pipes from 16 mm to 1,200 mm, together with an injection moulding facility making associated fittings for use by utilities companies for gas and water transfer.

Eight lines are powered by DC motors, many of which are over 20 years old. However, Line 12 had a high utilisation rate and yet the 182 kW DC motor was regularly failing, leading to an increase in downtime and rising maintenance costs. The company estimates that the annual static and dynamic checks, brush changes and outsourced labour costs alone are about £2,000 per motor.

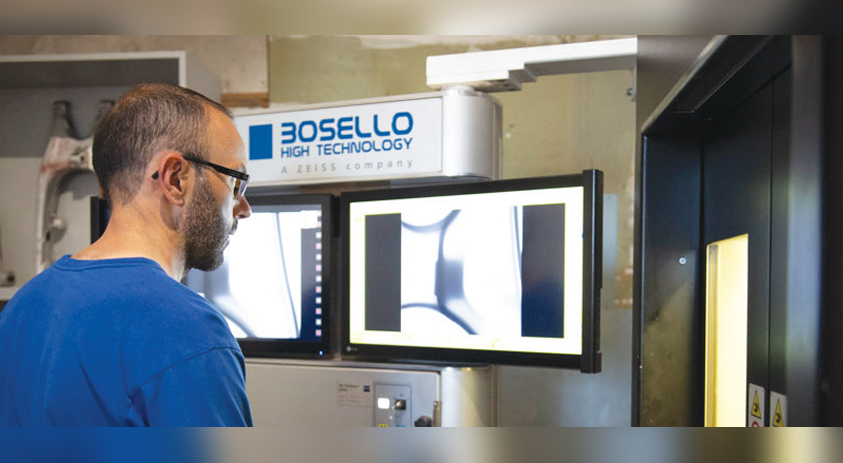

‘Before’ and ‘after’ monitoring ABB’s authorised value provider for the Derbyshire area, Inverter Drive Systems (IDS), was asked to carry out ‘before’ and ‘after’ monitoring of the DC motor on Line 12. This determines the energy savings while confirming that an investment in an AC motor and drive would meet Radius Systems’ three year capital payback policy. “Monitoring of the application is critical to the success of any installation,” explains Phil Nightingale, Sales Engineer, IDS. “It allows us to accurately determine the real energy saving potential which means we can size the AC motor and drive correctly. We are often able to reduce the size of the motor and drive package required while exceeding the production targets.”

It was through monitoring that IDS was able to determine the speed range of the line’s DC motor which revealed that it was over-sized for the application and hence consuming more energy than necessary. Also, despite the motor having been regularly maintained, it was 20 years old and nowhere near the efficiency for which it was originally designed.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.