From condition monitoring to Industry 4.0 and what the hydraulics industry has to offer

By OEM Update Editorial July 9, 2019 3:29 pm IST

Predictive maintenance is a process that has been implemented by numerous stakeholders in the manufacturing industry, such as component manufacturer, plant engineers and system operators. The digitisation of production and IoT (Internet of things), are at the forefront of innovation in every industry and it has become increasingly beneficial to research further applications of this technology. If every stakeholder contributes its expert knowledge to projects, the overall solution offers opportunities for everyone.

IoT may seem like a vague concept but it encompasses well-known processes such as condition monitoring and predictive maintenance. Preventative maintenance which is prescribed at fixed intervals by the manufacturers of the equipment, is a widespread practice in manufacturing plants used to decrease unexpected breakdowns. Often, intact components are replaced prematurely, thus wasting existing residual running times. Increasing cost pressure, a higher demand for machine availability and a growing interest in sustainable management are causing plant manufacturers and operators to look for alternatives.

Condition monitoring

Condition monitoring is the first step to restructure the operation of manufacturing plants by measuring and monitoring current system statuses. Sensors are mounted on the machinery and constantly sends status updates to a mainframe system in the factory, or alternatively the information is stored locally on the sensor.

The sensors react if the predefined values of a para- meter are exceeded or are not fulfilled, this may result in the machine shutting down operations to avoid any further irreparable damage. Subsequent to the cease in production, the customer service department is informed and if necessary spare parts are ordered. If the repairs cannot be executed internally an external engineer is commissioned to repair the machinery. The company incurs the cost because the machinery’s downtime causes an unexpected delay in production.

This causes costs for the plant operator. If an early warning threshold is set for the threshold values, the reaction can be initiated at an early stage: A first step towards predictive maintenance.

With this and all previous concepts, however, the environmental conditions of the plant are not yet taken into account or cannot be reliably estimated. Unforeseen external influences such as dusty surroundings, high humidity levels and extreme temperature fluctuations affect the overall system as well as the individual components installed within it. Friction and the wear of the internal components or a change in the state of the hydraulic fluid may occur the complete system due to ageing.

Condition monitoring in hydraulic systems:

The monitoring of the following system states is State of the art:

• Oil level in the tank

• Oil temperature in the system

• Filter contamination

• Current operating pressure

Predictive maintenance

Predictive maintenance is rapidly replacing reactive (operation until failure) or preventative maintenance, which have been common practices in the manufacturing industry. Component and system manufacturers are continuously working on new innovations that can eliminate the aforementioned weaknesses of condition monitoring. The goal of predictive maintenance is to find the optimal time for the respective preventive maintenance measure. Predictive maintenance should not be carried out too early, nor too late.

Predictive maintenance uses sensors that are placed on different machinery and tools. The development of sensor technology has enabled sensors to capture a significantly larger number of system parameters. The measured values are recorded and subsequently stored in a historical database that provides detailed information about the system status. The systematic recording of the change in the measured values coupled with the access to a structured database facilitates swift access to the current state of the system. Trends are analysed using algorithms which enables precise predictions ofmaintenance and change intervals with a low margin of error. Moreover, predictive maintenance allows the inclusion of environmental conditions in the analysis.

The challenges of implementing a predictive maintenance system are:

• The selection of measured variables

• The integration of sensors

• The formulation of the correct algorithms

Simulation models which are also known as digital twins, help predict system processes with precision based on the actual state of the system and its history. However, in complex scenarios, designing a model is complex and demanding due to the number of parameters and external factors that must be considered.

Data storage and analysis systems that have recently become available on the market make the measurement and capturing of large quantities of data possible which improves the evaluation system. The measured values and diagnostic data at the plant operator is sent from the machinery via networks to service providers or cloud service providers.

In addition, the targeted statistical evaluation of the data can also provide valuable information on product improvements at the component manufacturer or plant constructor, as well as potential for process optimisation at the plant operator.

For the plant manufacturer, however, this means higher acquisition costs in the beginning.

The suitable sensors must be selected and integrated into the system, evaluation algorithms developed and a connection to the database established. However, the manufacturer can offer the plant operator a plant with costs and probability of failure in operation significantly reduced. This is mainly achieved by optimisation of the system parameters and significantly better planning of maintenance and repair work in the company. The integration of these techniques is also known as Total Cost of Ownership (TCO).

The sensors must be selected and integrated into the manufacturing system, algorithms used for evaluation purposes must be developed and a link must be integrated into the database.

Predictive maintenance in a hydraulic system:

Monitoring of the following system parameters is possible in hydraulic systems but in certain cases the sensors to monitor the parameters have not yet been developed:

• Oil level in the tank

• Oil temperature in the system

• Filter contamination

• Current operating pressure

• Condition of the hydraulic fluid

• Oil contamination

• Presence/absence of water in the oil

• Viscosity of the oil

• Gas filling pressure in the hydraulic accumulator

•Valve switching position

Since each additional sensor reduces the manufacturing costs for the solution, it is particularly important that the system design a well-founded cost-benefit estimate to precede. Here, the component manufacturer can offer the system manufacturer comprehensive consulting services by providing demand-related concepts and developed an overview of the sensors available on the market.

Considering the high acquisition costs, the plant operator expects significant value added from the implementation of a predictive maintenance system. Depending on the industry it is necessary to consider the costs of machine or production downtime (e.g. automotive industry) and service costs (e.g. offshore wind power plant). Even safety is an element that is heavily considered in certain industries because a breakdown would have a severe impact on operations and may cause even more costly damages (e.g. malfunction of a brake in a wind turbine).

Today, intelligent sensor technology also offers possibilities to reduce the effort and computing power of the control centre by self-diagnosis and independent execution of decentralised logic functions. The sensor can either communicate bi-directionally with the higher-level controller or process the measurement data independently.

The condition of the hydraulic fluid is a vital indicator for the overall state of the system; therefore, it is imperative to regularly monitor the system. Constantly monitoring a hydraulic system is complex because a multitude of factors need to be considered such as; solid contamination, undissolved air, water contamination, unauthorised mixing and the operating temperature.

Different factors can be monitored and sensor technology is an integral part of that.

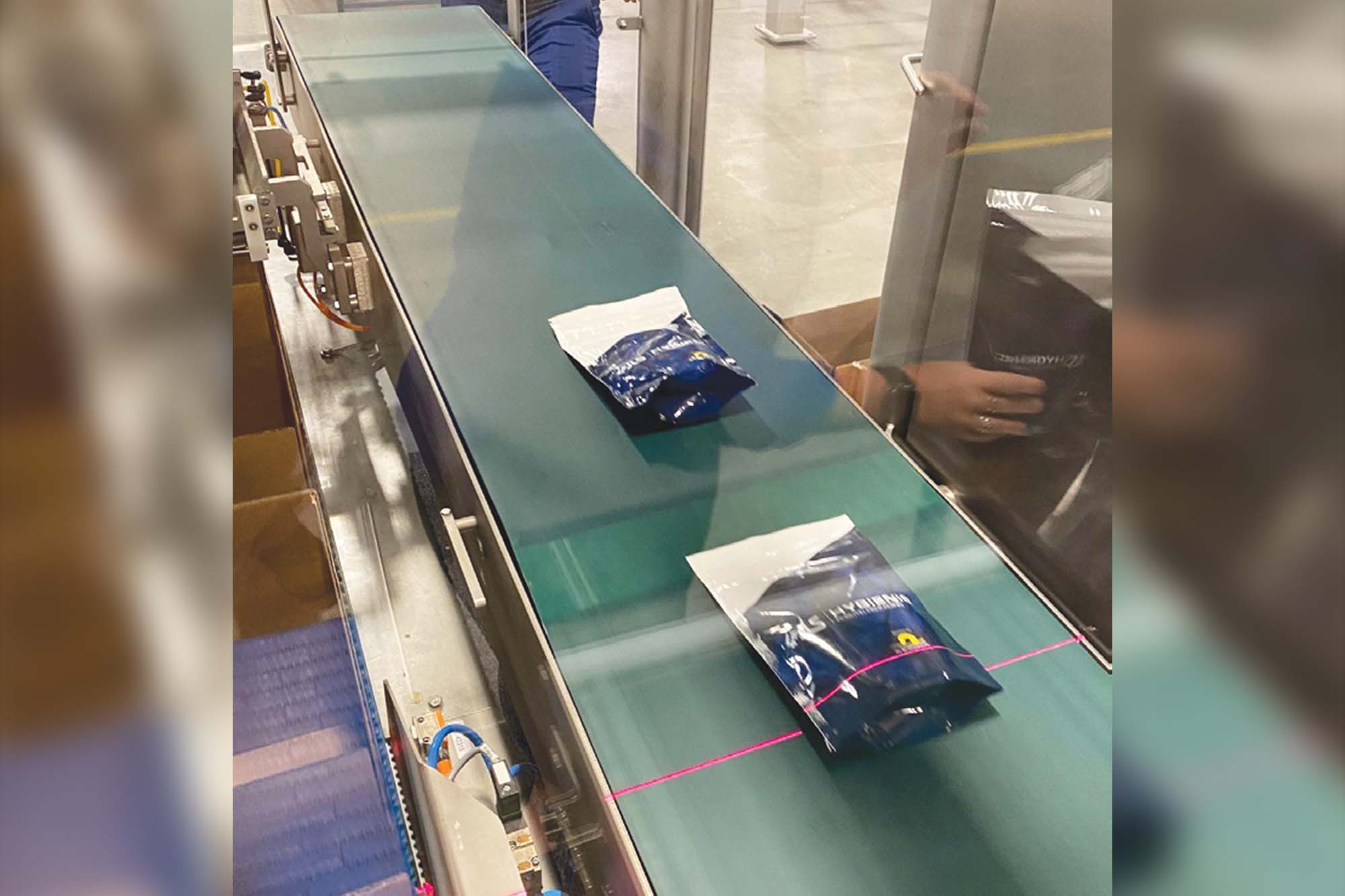

Application example:Smart hydraulic power units for machine tools

Hydraulic power units are reliable subsystems within machine tools and production plants. Already today the essential technical data are monitored by switches with pre-warning. For example, a necessary filter replacement can be placed in a planned maintenance period. IO-Link-compatible sensors can be installed in HAWE Hydraulik compact hydraulic power packs. They constantly record the status of the system and transfer the data to an analysis unit. This data is then transferred to a higher-level control system via a field bus. The result is an efficient and intelligent solution for industrial applications. However, the actual know-how consists in the development of suitable algorithms for the evaluation of the recorded sensor data. Short examples give a first impression.

• Filter contamination: Altering the differential pressure on the filter enables the technician to predict an accurate window of time when the filter needs to be replaced.

• Hydraulic accumulator pressure: A test cycle to monitor the pre-load pressure in the hydraulic accumulator can assess the information and provi- de an accurate estimation as to when the refill is necessary.

• Oil level in a tank: Continuous monitoring of the fill level enables the detection of external leakages and therefore the sensors can initiate the relevant measures necessary to avert a breakdown.

• Oil temperature: Continuous monitoring of the temperature allows the sensors to suggest downtimes for the component to avoid overheating.

• State of hydraulic fluid: Additional analyses are possible such as monitoring the wear of the pump and assessing the state of the oil.

Concretely implemented: Automated monitoring of the accumulator preload

Hydraulic units in machine tools are used for clamping functions. Depending on the design of the system, a hydraulic accumulator continuously supplies the hydraulic system with oil. The storage tank that is filled with gas must be inspected regularly to ensure functionality, currently this is done in fixed intervals prescribed by the manufacturer.

Predictive maintenance can be applied to this function by automating a test cycle for the pressure, which is integrated into the operating process. The preventative checks would eventually be eliminated and the refilling would be done in specific cases only when necessary.

In the context of clamping functions, a test cycle can be integrated into a hydraulic unit with attached memory. When oil is used as the memory parameter it can be emptied and refilled in a precise manner. As the pressure gradient increases and the oil parameter is taken into account, the current gas preload pressure can then be determined. As more data is stored over a longer period of time the algorithm is able to determine the gas refill intervals with increasing accuracy. If the accumulators are placed in the machine the effort made to measure the oil can be significantly reduced.

Industry 4.0

In the factory of the future, machines communicate with each other, products with each other and products with machines. And people just listen and observe? Networking offers a variety of possibilities not just for one production step, but for optimising the entire value chain. Information about the actual status and the history enable comprehensive evaluations and predictions.

There are already first examples in the industry of companies that have implemented the concept of Industry 4.0 into their manufacturing processes and are further developing the concept there. With Industry 4.0, the data is transferred in real time independent of the location of the machines or products. Some visions are briefly

summarised here.

Data of the machines and processes become available in real time and independent of your own location. To prevent the automation of process steps from becoming too complex, the establishment of networked, decentralized subsystems is being discussed.

Independent function modules, consisting of hardware and software, facilitate the structuring of increasingly

complex systems.

Industry 4.0 eliminates the conventional limits that exist in data structures and process organisation. The data exchanges between the system, software and the databases must be controlled. Offsite human-machine interfaces are commonly

used for this purpose.

Security and authorization concepts currently play an important role for all three target groups, plant operators, plant manufacturers and component manufacturers. Where are which data, services and functions executed and stored? It is precisely the point of data sovereignty that is discussed in every project on many levels between those involved. New utilization concepts are created both for components and the entire plant.

Conclusion

All parties (component manufacturers, plant engineers and system operators) have to combine their efforts to participate in the search for cost-efficient as well as safe automation concepts. Increased networking and joint targeted usage of data would benefit all parties. The speed and scope of implementation varies across industries. Areas of interest for system operator are:

• Decentralised automation at the field level

• Secure information processing and data management

• Stable networking process control systems

On the basis of a realistic consideration of effort and benefit, the measures should be defined jointly between component suppliers and plant manufacturers as well as between plant manufacturer and plant operator. The multifaceted requirements call for the pooling of different competencies in the project team and the involvement of external experts. From both an economic and a social point of view, this common approach will pay off for all participants.

This concept offers each party specific benefits for cost reduction and for improvements in performance such as:

The system operator avoids unexpected failures of the machinery. The availability of the plant increases as well as the product and quality processes. The plant engineer can better plan a maintenance or service assignment and stock necessary spare parts in good time. He can detect malfunctions and optimise system operation. The component manufacturer can manufacture the spare part on time. He receives important information on the failure probabilities and the service life of his products.

In this study, respondents already confirm the aspect of increasing performance, “According to 79 per cent of the study participants, the benefit of predictive maintenance for the customer lies primarily in increasing the performance of production technology, e.g. through higher plant availability, service life and more stable processes – in contrast, only just under one fifth of the companies see predictive maintenance as a lever for reducing maintenance costs.“

Conclusion

As a supplier of components and manufacturer of products, HAWE Hydraulik is facing up to the topic of digitisation in two dimensions. On the one hand, the company integrates as a development partner according to the customer requirements intelligent sensor technology in hydraulic power units and valve technology. Algorithms for evaluation are developed and, together with the system manufacturer, a demand-oriented complete concept has been worked out. For this purpose, the configuration data is stored before delivery of the products, operating data during operation or an error status in the event of service are stored in a customer-related way and evaluated. Using a data matrix code, this data is to be made accessible easier even for the plant engineer and the system operator in the future.

On the other hand, HAWE Hydraulik records field data in its own production facilities and analyses them from a wide variety of points of view. In the process, very practical empirical values can be gained, e.g. on the influences of the environment and individual operation.

These findings then flow into the selection of suitable sensor technology, the creation of algorithms and the data management of the company‘s own components. Know-how and experience grow with each customer project. This also benefits the company‘s own product development and the development of an attractive range of services for customers.

For more details, contact:

HAWE Hydraulik SE

Einsteinring 17

DE-85609 Aschheim / Munich

Phone:+4989379100-1000

info@hawe.dewww.hawe.com

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.