Flying high at Airbus

By OEM Update Editorial September 21, 2022 2:40 pm IST

Airbus is selling so well that the demand to increase the build rate has never been higher. BAE Systems needed a simple way to improve throughput — it found the answer in VERICUT.

Modern high-speed machine tools are equipped with digital control systems incorporating elaborate algorithms to ensure the machine does not shake itself to pieces when contouring at feeds over 20m/min. These features, more commonly known as the acceleration/ deceleration curves, work exceptionally well in most applications.

Project BAE Systems Filton, UK, found the features to be an inhibiting factor when trying to optimise the production of key components for the wing structures of Airbus planes. It was not straightforward initially; you cannot simply switch such control parameters off and hope for the best. That would have led to some very unpredictable situations. So instead, BAE Systems set about contacting tooling and software companies for a solution. The result was a very successful project involving CGTech and Kennametal.

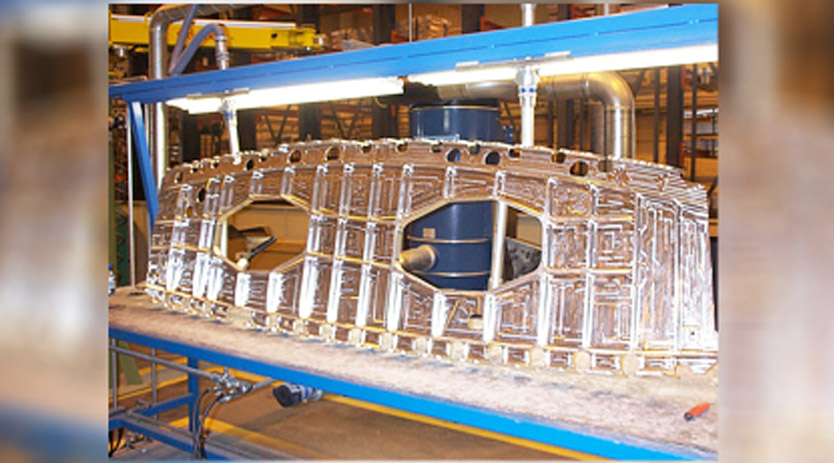

Both companies set about optimising the setup on Cell F, comprised of Mori Seiki SH-50 machining centres and mainly used to cut aluminium A-Frames for the A330/340 Airbus. These come in 60 variations and are situated along the leading edge of the wings. There was no need to change the fundamental setup; material already arrived on a JIT basis pre-blocked, skimmed, and drilled, ready for fixtures. So it was back to optimising feeds and speeds.

Optipath to control parameters

OptiPath® was used to override various control parameters, while Kennametal’s tooling allowed efficient cutting at higher feeds and speeds. VERICUT’s OptiPath reads the NC tool path file and divides motion into several smaller segments. Because VERICUT mathematically subtracts the material cut away from the model, the software always knows the depth/ width/angle of cut and the amount of material removed. Where necessary, OptiPath assigns the best feed rate for each cutting condition encountered based on the amount of material removed in each segment. It then outputs a new tool path, identical to the original but with improved feed rates.

The principle is simple – the shallower the cut, the faster the feed rate. To keep material cutting rather than just tearing at these accelerated feed rates, the spindle speed is ramped up accordingly. For deeper cuts, the reverse is applied.

Methodology AdoptionMatt Godfrey, EIT team leader, said, “CGTech got involved in helping us to get the best out of our NC programs and changing the mindset at Filton. We swapped tools for ones with longer flute lengths, took greater cut depths, and got better finishes. We didn’t have to change the part programs whatsoever. OptiPath took care of feed rates for us – we just capped the programs at 7m/min. The feed rate to stop thin cuts ramps up to 16m/min. This would have given us unacceptable surface finishes for aerospace work. The original program was set up to cut at around 1m/min. We now have improved accuracy and better tool utilisation.”

Filton experimented with two optimisation methods: ‘Constant Volume’ and ‘Constant Chip’ thickness. Operators found the constant volume method was more suited to the A-Frames. Using this method, the run time was cut by 25 percent, and throughput increased by 15 percent – with the largest savings on roughing.

To ensure the master programs are never altered, subdirectories were set up to handle the optimised versions of each program. These are downloaded over the shop floor DNC system just as any NC program. They are standard programs – the only difference is they contain optimised feeds and speeds. An attempt to do this manually would likely result in hours of programming time for minimal benefit.

They also use OptiPath to optimise part programs for Airbus ribs which run on Cell G, equipped with the older type Marwin Automax II machining centres. These machines do not run using standard G-code. Instead, they use the direct CL output from the CAM system. The CL data is processed by the machine tool using tool diameter, and a tool probing system measures length data. “To get around this, we had a ‘reverse post’ written,” says Godfrey. The CL file is run through Expertec software to turn it into a G-code file, and then it’s optimised using OptiPath and turned back into a CL file. Godfrey is currently concentrating on roughing where the savings are the greatest. So far, the results have been excellent. The roughing procedure has improved so much that the swarf removal capability of the machines had to be upgraded.

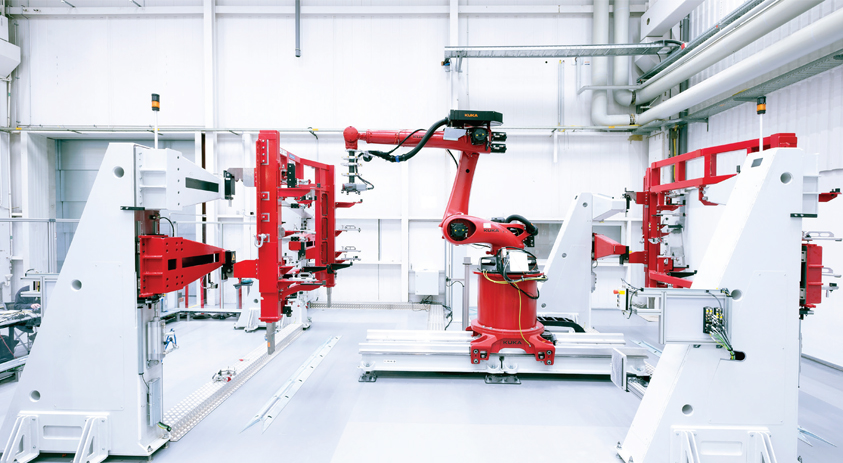

A special project team is currently being assembled to roll the benefits seen on cells F and G across all five cells at the Filton plant. One cell that will particularly benefit is Cell W – a new £8 million Forest-Line installation. Cell W consists of three sizeable high-speed machining centres fed by an automatic pallet system designed to machine 330/340 Airbus ribs. “Once the programmers for this cell have finished training on OptiPath we’ll start using it,” says Godfrey. Another Cell destined for OptiPath is cell E – Mori Seiki machining centres – exclusively used in machining titanium components.

For more information visit: www. cgtech.co.in

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.