e-F@ctory in action

By OEM Update Editorial November 13, 2018 5:08 pm IST

The application of e-F@ctory at Mitsubishi Electric’s Kani manufacturing facility, part of its Nagoya Works, Japan, has led to a number of hugely beneficial outcomes. For instance, by redesigning the process and reintegrating a human element where there was once 100 per cent automation, a single line that previously occupied 280 sqm has been reduced to a cell of just 44.1 sqm. This 84 per cent reduction in space means that the productivity of each square metre of production hall had been increased through greater utilisation.

Mitsubishi Electric’s Kani factory, which produces motor starters and contactors, was facing a number of significant challenges, not least the sheer number of product variations and possible configurations in its product range – some 14,000 in fact. Demand from customers for greater choice had served to dilute the volumes of each particular product, despite overall product quantities increasing substantially.

Automation not always the answer

In the past, manual production at the Kani factory had given way to totally automated assembly lines, which were ideal for mass production with few product variations where high yields could be realised at high speed. However, one problem lay with the fact that many individual components were required to be in stock and ready for the manufacturing process – without which the lines would not be able to run for any appreciable length of time.

For various reasons, substantial numbers of assembly lines had been optimised to produce a limited range of products, and these would stand still when the components run out. In such a scenario, it becomes difficult and uneconomical to produce small batches.

Overcoming the issue

The solution was to employ engineering know-how built up over many years and combine this with a vision of integrated manufacturing – known as the Mitsubishi Electric e-F@ctory concept. In tandem, existing technology and third-party relationships were utilised through the e-F@ctory Alliance, CLPA and other collaborative engineering groups. Put simply, the objective was to perfect the ‘art of manufacturing’ or, as it is known in Japan, ‘monozukuri’.

So, where to start? The major challenge was to find the root cause of any inconsistencies. This task involved several approaches, from analysing existing data or collecting new data sets for fresh eyes to review, to look for links between data which can appear unlinked on the surface. This factor is related to the first principles of IIoT or Industry 4.0.

Studying existing processes, as well as the methodology, revealed that natural, normal, organic growth in the production process had inadvertently led to inefficiencies.

Challenging the assumptions

Resolving this issue at the Kani factory of Mitsubishi Electric, led to a re-evaluation of the need of 100 per cent automated lines, which were not necessarily the most efficient. Restoring some human elements could potentially reduce manufacturing anomalies.Further observations revealed that the automated parts feeding of some larger components not only created a bottleneck, but led to the parts feeders consuming large volumes of space which could, under specific conditions, result in minor damage to the components. Not enough to cause an issue, but enough that the engineers were dissatisfied with the quality level being achieved.

Conversely, the automation of some tasks which had, in the past, seemed impossible, now looked possible through a combination of technologies. An example of this thinking concerned the misalignment of certain screws during the assembly process. The automation system, un-aware of the misalignment, would try to insert the screw and cause damage to the entrance of the hole.

Two technologies helped to overcome this problem: the automatic alignment of robots and combining rotational drives for inserting the screws using torque sensors. As a result, the hole can now be located easily and aligned correctly every time. Moreover, the torque sensor confirms the absence of misalignment and that the screw is tightened to the correct level. The increased use of vision systems, checking for correct assembly and alignment, has also helped to increase the number of right-first-time products.

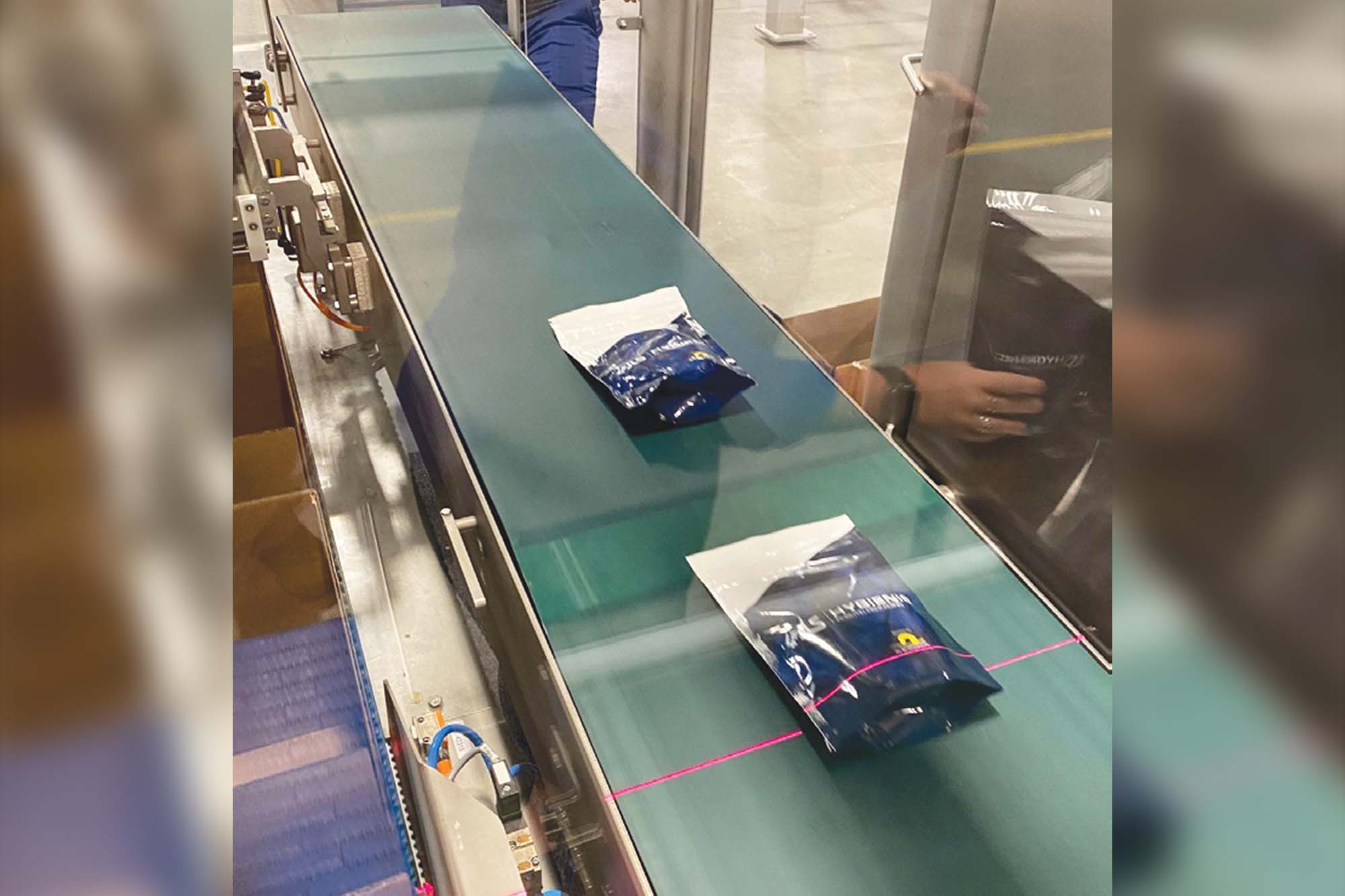

A further, simpler idea was to etch a matrix code on the body of each product and track it through the various stages. Now, as the product arrives at a workstation, its code is read and the appropriate processes and parts applied. At the end of the manufacturing cycle, each product then has a traceable manufacturing history, making it entirely possible to track the history of individual issues.

Smaller area, greater efficiency

By redesigning the process and reintegrating the human element, a single line, which comprised two 35m-long segments occupying some 280 sqm, has been reduced to a cell of just 44.1 sqm. This 84 per cent reduction in space means that the productivity of each square metre of production hall has been increased through greater utilisation. Even though a single new cell cannot produce the same volume and speed of units as the original fully automated line, it is now possible to deploy up to 6.3 cells in the same space. In turn, total productivity density is much higher thanks to three key factors: a wider variety of products can be manufactured in smaller batches, one stoppage does not halt the whole of production, and the total number of production lines has increased.

The end result is effective optimisation of both machine and human re-sources, as well as the production process and space – a true productivity gains.

Growing the e-F@ctory story

While many in engineering are familiar with Japanese manufacturing mantras as Kaizen, Toyota’s 7 principles and Just in Time, few people outside Asia have experienced the e-F@ctory concept. However, as can be seen at the Kani factory, by learning more about Mitsubishi Electric e-F@ctory, manufacturers can achieve their own smart factory concepts – whether they are called Industry 4.0, IIoT or ‘Made in China 2025’.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.