Automating the impossible in any factory

By Staff Report August 9, 2024 5:53 pm IST

Explore how Bosch Rexroth combined the Anybus Communicator with their Smart Flex Effector to bring a versatile compensation module for industrial automation.

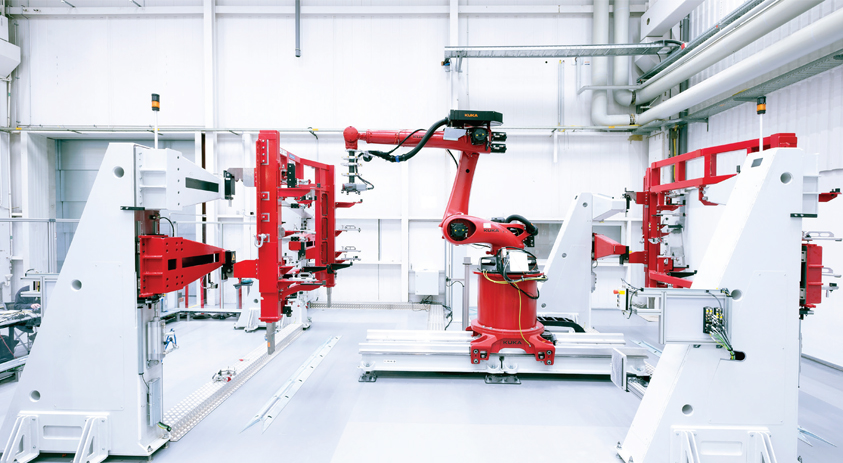

Bosch Rexroth, the automation branch of the Bosch group, specialises in advanced drive and control technologies. At their Customer and Innovation Center in Ulm, Germany, they develop solutions for the future of automation, such as the Smart Flex Effector, a compensation module aiming to revolutionise the industry.

Smart Flex Effector – Automate the Impossible

David Lehmann, System Architect at Bosch Rexroth, explains what a compensation module is and what makes the Smart Flex Effector unique, stating, “When you think about a robot in the factory, you usually think of a six-axis robot assembling parts or building a car, or something like that. The robots have some tools at the tip, like a gripper. The compensation module is the part that goes between the robot arm and the gripper. The Smart Flex Effector stands out due to its ability to provide compliance (flexibility in response to forces) in six degrees of freedom (movement in three-dimensional space). With an integrated sensor system, we can accurately measure the tool’s deflection (change in position). This allows us to perform complex tasks, such as precise assembly operations, that usually only humans can do. Our slogan, ‘Automate the impossible’, sums it up nicely. Our goal with this product is to enable robots to perform new tasks that they are traditionally not good at, thereby increasing efficiency and productivity.”

Connectivity challenges

To enable the robots to perform these new tasks, the Smart Flex Effector needs to exchange position measurement data with the robot controllers, including information about the tool’s deflection and control signals for the module’s locked and unlocked states.

However, connecting the Smart Flex Effector to robot controllers was challenging; as David explains, “Our product was available, but we had difficulties installing it at our customer’s sites. When we talked to our customers, the feedback was often the same: ‘You have this serial interface, but I don’t want to spend two weeks or more trying to connect it with my robot controller. I do not have the time or the resources to do that.’”

Simplifying connectivity with Anybus protocol converters

To solve these connectivity challenges, Bosch Rexroth turned to HMS Networks who provided the Anybus Communicator Common Ethernet, a ready-made protocol converter capable of connecting serial devices to EtherCAT, EtherNet/IP, Modbus TCP or PROFINET controllers. HMS Networks AB provides solutions in industrial information and communication technology. HMS develops and manufactures products under the Anybus®, Ixxat®, Ewon®, and Intesis® brands (Red Lion® Controls is also a part of the HMS Group as of April 2024).A key benefit of the Anybus Communicator Common Ethernet was that the same unit could connect to all the major Ethernet protocols. David describes it as “This Anybus protocol converter was the ideal solution for us because we can reconfigure it with a firmware update, and with just one unit, we can provide the connection to the different protocols.”

The Anybus Communicator’s intuitive user interface also won some new fans. “The interface is nice. We tested it in our lab before selling it to our customers, where application engineers completed feasibility studies. They all said it was easy to complete the required configurations via the web interface, which was important to us as we have customers who are not experts in automation and robotics.”

The Anybus Communicator could be installed via a web browser. Bosch and their customers prefer not to install third-party configuration software. It adds security risks and complexity – just getting the required admin rights often delays installations.

Smart Flex Effector + Anybus Communicator = The complete solution

The Smart Flex Effector and Anybus Communicator have worked so well together that Bosch Rexroth includes the Anybus Communicator as part of a complete solution. They decided to create an order number for the Anybus convertor so that customers could buy it directly from them. Bosch thus sells both devices together as a complete solution.

Expanded market

With the addition of the Anybus Communicator, Bosch Rexroth can easily connect to all the major Industrial Ethernet protocols and, as a result, has expanded its market. “Now we really can address more or less the whole market”, David concludes. “We can cover everything; we haven’t found a robot with a Fieldbus connection that is not supported by this Anybus converter yet.”

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.