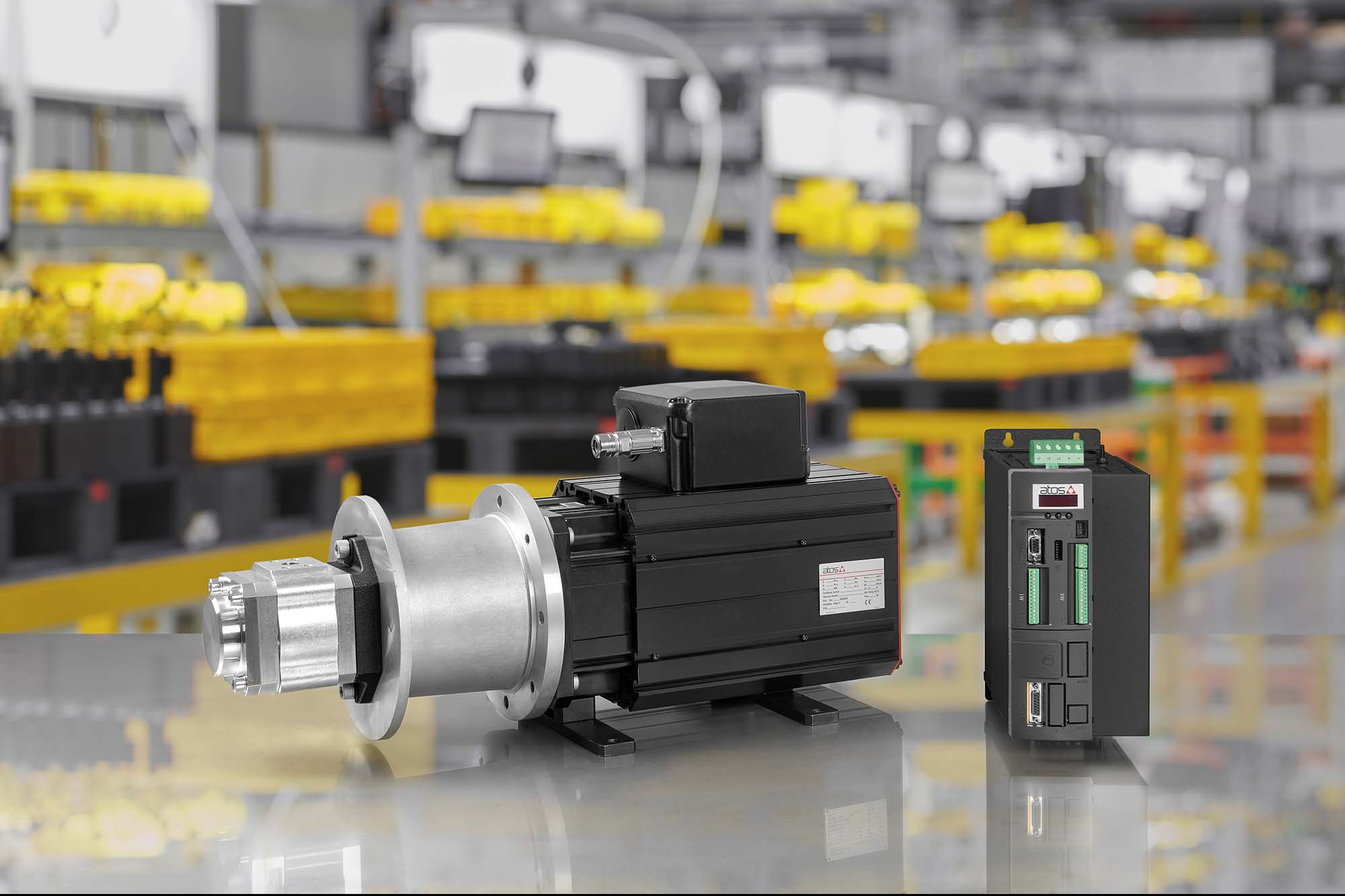

SSP energy-saving Smart ServoPump with pq control

By OEM Update Editorial December 21, 2023 2:39 pm IST

The growing concern over environmental pollution and the rising energy costs are compelling markets to seek more efficient technologies and solutions. Atos provides the optimal response through its array of energy-saving servopumps equipped with pq control.

ATOS pumps are efficient, capable of saving up to 80 percent of energy, making them the most efficient to generate hydraulic power.

Energy saving servopump vs traditional systems

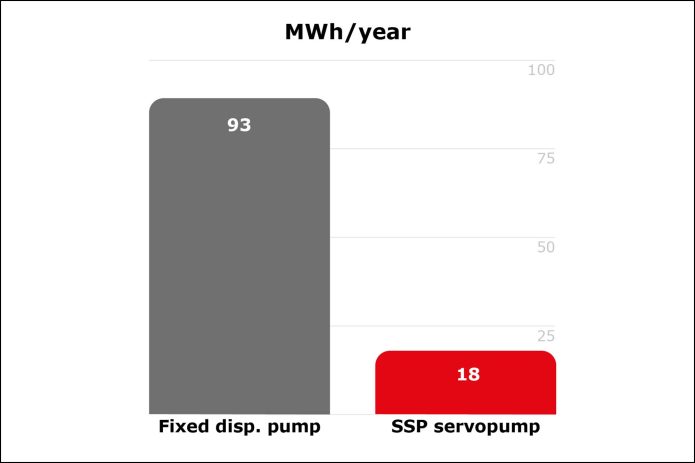

Unlike traditional systems that feature asynchronous motors operating at a constant speed, producing pressurized oil even when the machine cycle doesn’t demand it, a servopump delivers hydraulic power precisely in the quantity needed for the ongoing work phase.

Comparative analyses, performed on a 300 tons plastic injection molding machine, revealed that the energy consumption of the SSP servopump has been lower than 80 % with respect to fixed displacement pump, leading to annual savings of 75 MWh and 11,7 tons of CO2.

The ATOS difference

Atos’ R&D department has introduced innovative functionalities to streamline and simplify the experience with the servopump.

The Smart Start-up feature streamlines SSP servopump commissioning by offering an intuitive wizard procedure that configures, tests, and auto-tunes the servopump for optimal dynamic response in three simple steps.

Atos leveraged its electrohydraulic expertise to craft a specialized P/Q algorithm- Hydraulicpq control algorithm- for SSP servopump control, tailored specifically for hydraulic axes. This eliminates the need for hydraulic machinery manufacturers to create their own control algorithms, easing their workload.

Through extensive R&D tests and Modeling and Simulation, Atos developed patented algorithms that simplify SSP servopump commissioning and management. Autotuning eliminates the manual setup by automatically configuring the servopump parameters for precise and stable pressure control. Smart cooling prevents overheating during extended static pressure control phases by estimating internal pump temperature without the use of any transducer. If the temperature exceeds limits, drain valve for oil recirculation is activated which allows a reduction of pump temperature.SSP control facilitates real-time selection of the optimal axis configuration, ensuring maximum performance for each hydraulic axis of the machine.

The high efficiency of the servopump enables downsizing of the hydraulic power unit. Atos provides the S-SW-SIZING software, guiding users in selecting the most suitable servopump by inputting the desired machine cycle. Additionally, the software estimates the system’s energy consumption, highlighting the CO2 and operational cost savings compared to conventional systems.

Servopump with pq control: much more than energy saving

The motor-pump’s integrated angular position transducer enables precise estimation of the instant flow rate, ensuring superior accuracy and repeatability in flow control compared to proportional valves.

The exceptional efficiency of the SSP system leads to reduced tank size and eliminates the need for a heat exchanger. Additionally, its capability to achieve higher rotational speeds allows for a decrease in pump displacement.

Compared to a variable displacement pump, the SSP system emits significantly lower noise levels, registering as low as 7 dB during flow control and 20 dB during pressure control. This is attributed to the internal gear pump’s low noise output and the motor-pump unit’s ability to modulate its speed.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.