Smart factories harness smart technology

By OEM Update Editorial December 21, 2023 1:48 pm IST

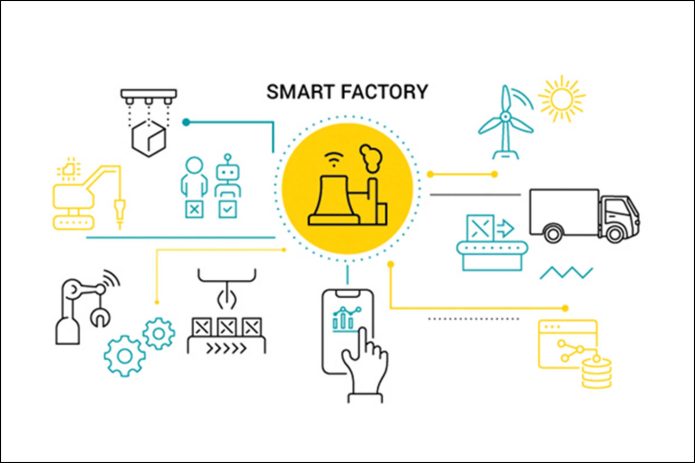

A Smart factory epitomises exceptional energy efficiency by fully utilising smart technology. It denotes a contemporary production site where interconnected devices, machinery, and production systems gather and exchange information.

Smart factory stands out as a pinnacle of energy efficiency, harnessing smart technology to its fullest potential. It represents a modernised manufacturing facility where interconnected devices, machinery, and production systems seamlessly gather and exchange data. This data is the foundation for enhancing operational processes and addressing challenges.

The primary aim of a smart factory is to attain complete autonomy. This means utilising precise data analysis to quickly identify and rectify malfunctions or enhance processes seamlessly without interrupting production. This interconnected ecosystem enables ongoing process enhancements through automation and self-optimisation.

Chicago Pneumatic is focused on achieving the goal of reducing carbon emissions and minimising the carbon footprint while enhancing production efficiency. This commitment is showcased by introducing intelligent technologies like ‘Permanent Magnet Technology, VFD Compressors, E-Control, Icons, and Airchitect’. These cutting-edge solutions enable customers to create smart factories, maximising their capabilities and aligning precisely with their individual needs.

Permanent Magnet Technology

IPM technology as the preferred choice: The attractiveness of IPM technology stems from its emphasis on reducing energy costs, accommodating variable air demands, and achieving improved efficiency through innovative motor design and dependable construction.

Energy costs constitute a significant share, approximately 70 to 80 percent, of a compressor’s overall ownership expenses, making it a crucial consideration. Customers often face varying demands for compressed air, driving the need for adaptability. With an IE4 Super Premium Efficiency iPM motor, this technology achieves up to 5 percent greater energy efficiency than IE2/IE3 induction motors in CPMV. The direct drive configuration optimises savings, while its latest IP Protection class ensures enhanced durability. The proven oil-cooled design guarantees reliable performance, and its horizontal configuration facilitates maintenance. It is an entirely ‘In-House’ design and promises reliable and seamless integration.

Variable frequency drive technology

Chicago Pneumatic’s variable frequency drive (VFD) compressors, also known as Inverter compressors, efficiently reduce power consumption by up to 30 percent. Over 5 years, energy expenses constitute about 77 percent of the total operational cost of your compressor, highlighting the significant focus on diminishing the operational expenses of compressed air solutions. This technology ensures an optimal synchronisation between air supply and demand, eliminating unnecessary unload cycles beyond the 20 percent load threshold. Moreover, it incorporates a soft start-up mechanism, reducing peak currents for a more seamless operational performance.

E-control

The ECOntrol 6 system defines and aligns compressed air requirements with precise air supply. This optimised energy consumption results in optimised energy usage and substantial cost savings. Effectively managing your compressor or compressed air network yields numerous benefits. Our ECOntrol 6 central control system efficiently monitors and controls one or multiple compressors, enhancing overall performance.

ECOntrol 6 ensures a transparent and efficient compressed air process, delivering significant value to your network.

Icons : Intelligent connectivity System

Effortlessly monitor your compressed air setup from any location using your computer, tablet, or mobile device. ICONS eliminates the need for service log books or regular visits to the compressor room. Access your compressor’s real-time service status online with just a simple click. You can directly connect with your compressor supplier through a convenient link to request a service quote. This user-friendly and readily accessible solution offers quick and consistent support whenever needed.

Airchitect Audit

Chicago Pneumatic compressors is introducing “Airchitect,” the Future of Air Audits solution that helps you compute savings and guides them toward your bank account.

Airchitect offers distinct advantages. It addresses issues such as up to 35 percent energy losses during unloading, highlighting the need for efficient load management. Additionally, the system recognises that each 1-bar decrease in pressure output yields approximately 7 percent energy savings, underlining the significance of maintaining optimal pressure levels. Moreover, Airchitect targets older installations that may experience up to 20 percent leakages, emphasising the importance of addressing inefficiencies for improved overall performance.

Reach us at: customer.care@cp.com

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.