Precision and rigidity: The PMI way

By OEM Update Editorial July 8, 2024 7:07 pm IST

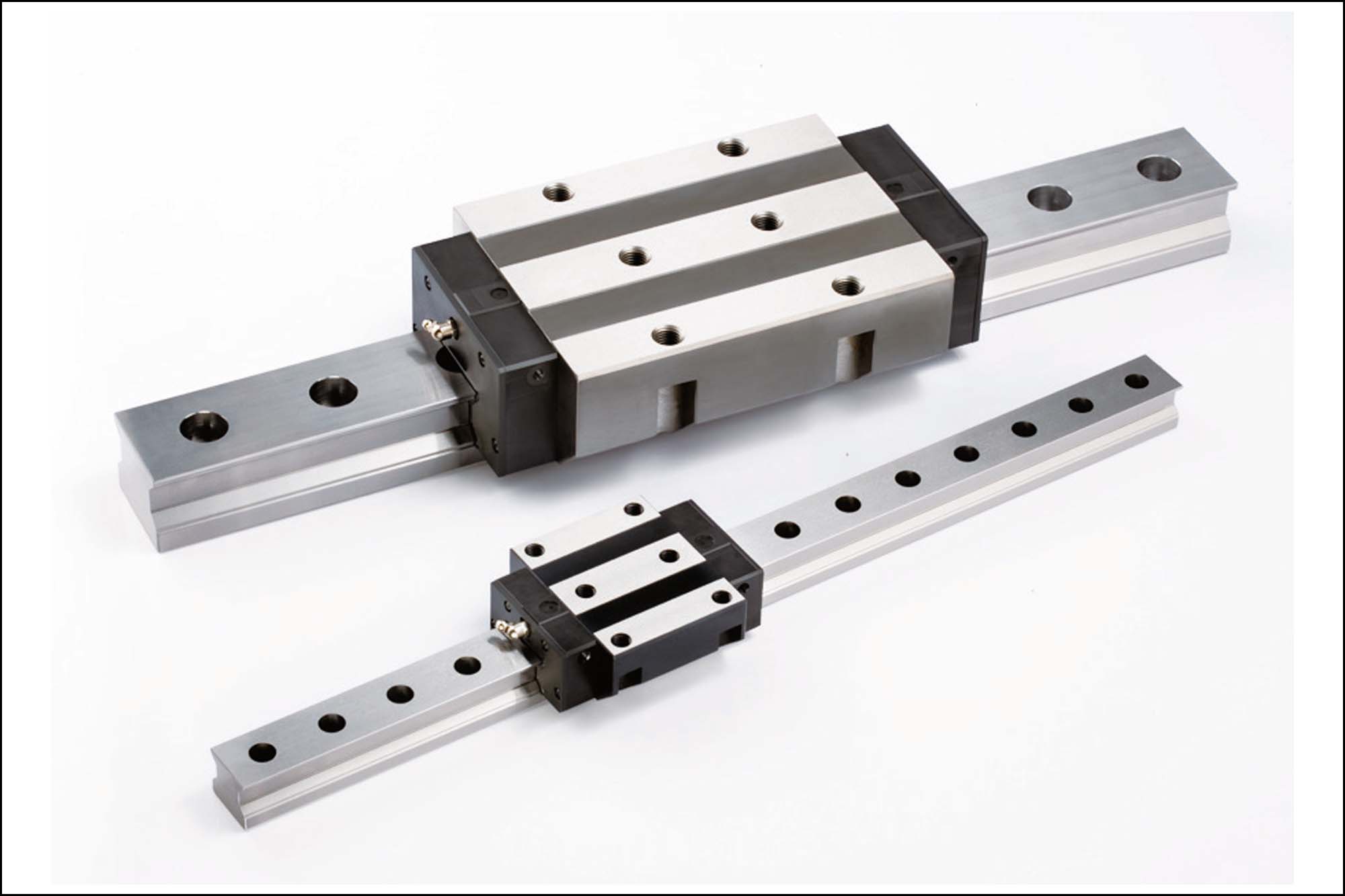

PMI roller guideways are crucial for precise linear motion in machinery, featuring built-in rollers on a rail for minimal friction. Known for high load capacity and stability, they ensure smooth, accurate movement in heavy-duty applications.

Roller guideways

These guideways consist of a rail with built-in rollers and a carriage that moves along the rail with minimal friction. The rollers in PMI roller guideways are designed to distribute the load evenly, ensuring smooth and stable motion even under heavy loads.

One of the key advantages of PMI roller guideways is their high load-carrying capacity. The design of the rollers and the raceways allows for the distribution of loads over a larger contact area, making them suitable for applications that require the movement of heavy loads with high precision.

PMI roller guideways are also known for their rigidity and stability. The design of the rollers and the rail structure provides increased stiffness, reducing vibration and ensuring consistent positioning accuracy, even in high-speed or high-load applications.

PMI roller guideways are a popular choice in various industries, such as machine tools, automation, semiconductor manufacturing, and more, where precise linear motion control is essential. Their robust construction, high load capacity, rigidity, and smooth operation make them a reliable solution for demanding applications that require efficient and accurate linear motion control.

PMI ground ballscrews are precision mechanical devices used in machinery and automation systems.

Ground ballscrew

They convert rotary motion into linear motion with high efficiency and accuracy. These ballscrews are designed with precision-ground threads to ensure smooth operation, low friction, and excellent positioning accuracy.

One of the key features of PMI ground ballscrews is their high precision. The threads on the ballscrew shaft are meticulously ground to tight tolerances, resulting in smooth motion and consistent positioning accuracy. This level of precision is crucial in applications that require fine control and repeatability, such as CNC machines, industrial robots, and semiconductor manufacturing equipment.

PMI ground ballscrews also offer high efficiency due to their low friction design. The use of precision ground ball bearings between the screw shaft and the nut reduces friction, resulting in smoother operation and energy savings. This efficiency is essential for applications that demand high-speed and high-precision linear motion.

Contact us at: www.superslides.in / 022-4935-5555 / sales@superslides.in

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.