Increasing laser cutting performance with Reckon & Romax

By OEM Update Editorial December 1, 2023 12:22 pm IST

Reckon gearboxes can seamlessly replace similar-sized gearboxes with compatible interfaces without any risk. However, when customers are designing new systems, the responsibility lies in recommending a reliable solution that matches all specifications.

Planetary gearboxes are prescribed in 2 different situations: as a one-to-one replacement of a competitor product or in a new customer development. Recommending an alternative product in an existing application is easy, as our engineers know that their design is safe. From a customer perspective, there is a rising perception that using standard catalogue information to determine gearbox size could be more precise and carry risks. More engineers are starting to question the accuracy of values presented in datasheets. The recent increase in published performance figures by certain suppliers is intriguing and seems inexplicable solely through advancements in design, materials, treatments, or lubricants.

Customers now expect manufacturers to argue recommendations based on solid, reliable data. Explaining to our customers the reasons for the difference between our torque ratings and competition’s is not easy. Ten different gear designers may give ten different torque ratings to the same gearbox based on which norm (or which version of the norm) they are following, the safety margin they choose to apply, the calculation scenario they decide to follow (speed, heat, value and localization of the shaft loads). Understanding the methodology behind the data calculation is crucial to answering the question, although this information is typically not detailed in the catalogues. The gearbox labelled with the highest torque rating might not be the optimal choice; in fact, it could indicate the removal of safety margins to present more favourable data, which we consider to be misleading.

Our industry’s authentic datasheet ratings might rely on standards that solely account for an ideal scenario, assuming precise part placement and flawless manufacturing. Real-world conditions diverge significantly from these idealized situations, where radial loads on the shaft can impact the gearbox’s output bearings. It also impacts the shaft, illustrating a stark contrast between theoretical expectations and practical outcomes.

Romax Enduro stands out by factoring in all these variables, providing a more precise estimation of real-world conditions than any previous software we’ve utilised. Our capability to demonstrate our product’s performance across various applications is a testament to its accuracy in depicting real-life behaviours.

Romax, an English company, goes beyond mere integration by incorporating the latest revisions of calculation standards, such as ISO 6336-2:2006 for gear calculation and TS 16281:2008 for bearing calculation. Moreover, they collaborate with esteemed global experts to craft their proprietary algorithms, enhancing their software’s capabilities beyond established norms. Functions now available in Romax Enduro enable increasing design reliability and estimating very precisely the life of a complete gearbox, considering all aspects of real-life conditions. Using Romax, we can now estimate the life of each gearbox in our customers application, component by component, taking into account the impact of one component on the other and, more importantly, considering your output element as a part of the system.

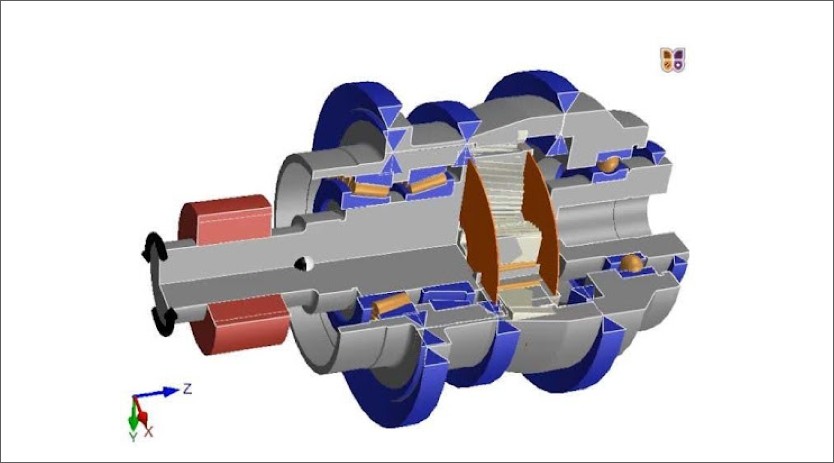

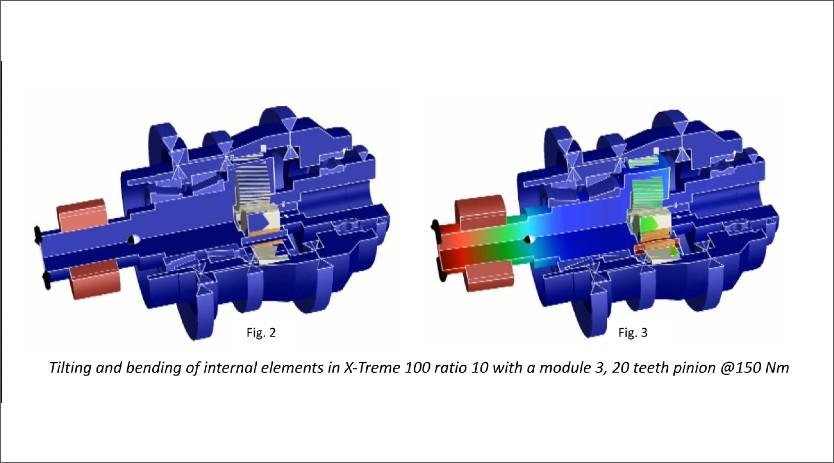

The following phenomenon is typicalIn a rack and pinion transmission, a common occurrence involves aggregating loads from the helical pinion, which impacts the output shaft. This process involves bending and tilting the output shaft around the output bearings, causing a twisting effect on the planet carrier. Consequently, this action compresses the ring gear onto the gears, creating pressure on multiple components, such as the needles against the planets and the planets against the sun gear, ultimately resulting in a radial load applied to the customer’s motor shaft. As a result, the sun gear suffers more than what the basic norms can estimate (basic algorithms will only give L10h results) and becomes the weak element in the system. Romax Enduro can tell us the damage to each of these elements!

The result of such a calculation is conservative when compared with standard datasheet ratings. In such applications or working conditions, the same gearbox can be rated a certain torque value or only half of this value. But it is a fact that shafts, bearings, planet carriers, gears, needles, axles, etc., all have their stiffness. Who would prefer trusting catalogue values that do not consider such a phenomenon?

Romax Enduro makes recommendations precise and professional

We can now tell you the difference in any internal element lifetime if you use a 25-teeth pinion rather than a 20-teeth pinion. The resulting additional shaft torsion, flexion and tilt will reduce the size of the zone where the planets are transferred power from the sun gear or transfer this power to the ring gear (this factor called the Khβ is clearly displayed in the results). Our engineers can show you that a 160 Nm gearbox is only a 120 Nm gearbox if you install a spiral bevel gear on its output shaft because the radial and axial load generated by the bevel gear set will compress and deform the output bearings and tilt all the components inside above this torque. We can tell you that adding two teeth to your pinion and increasing the ratio slightly can sometimes increase, sometimes decrease the overall life, depending on the initial ratio.

We are prepared to provide our customers with impeccable recommendations because even the most exceptional products can only deliver optimal performance if properly sized. We aim to ensure their applications achieve the longest lifespan and optimal performance by offering the ideal guidance.

For more information: Amcats Pvt. Ltd., Turbhe, Navi Mumbai 400705.

Tel: +91 22 6146 4444 / 25550900; Whatsapp: +91 7208880057

Email: sales@amcats.com

Expertise shared by – Martin MIJNO, CEO and founder, Reckon Drives International SAS, France.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.