Generating gear hard-finishing processes ready for the future

By admin February 4, 2023 1:43 pm IST

Up-to-date CNC technology, process monitoring, and comprehensive interfaces, for example, IO-link, OPC-UA, and Gear Data Exchange, have readied these machines for industry 4.0 requirements.

Reishauer, a Swiss machine tool company, has been at the forefront of hard-finishing processes since 1945 when the company invented the generating gear grinding process. Today, Reishauer manufactures all the necessary tooling, such as grinding wheels, diamond dressing tools, and work holding. The overarching idea of making everything in-house is to assume full responsibility for the manufacturing process to ensure excellent quality, reduced costs, and high output. The grinding machine portfolio includes generating gear grinders for workpieces from 5 to 1000 mm in diameter. For high-volume productions prevalent in the automotive industry, Reishauer offers its twin-spindle concept. While one workpiece spindle is engaged in grinding, the second one is loaded to reduce non- productive time to the absolute minimum.

Generation grinding machine series Rzx60 4.0

Over 1000 RZx60 machines in the market have proven themselves as successful concept. Building on this experience, the machine concept has been revised and adapted to the requirements of Industry 4.0 applications. The 4.0 series still features the proven twin-spindle technology. However, this has been complemented with the latest control technology and modern interfaces for Industry 4.0 applications. This article discusses two features: The RSP CNC Control and the ARGUS process monitoring system. One of the machine types, the RZ160 KWS, allows the grinding of gears with interference contours, as shown in Illustration 1. All the RZx60 machines have been designed explicitly with industry 4.0 requirements in mind. The RZx60 4.0 series still feature the proven twin-spindle technology of their predecessors. Up-to- date CNC technology, process monitoring, and comprehensive interfaces, for example, IO- link, OPC-UA, and GDE (Gear Data Exchange), have readied these machines for industry 4.0 requirements. The software platform RSP has augmented user-friendliness and offers optimised user support such as graphic guidance during setup, active error prevention, and comprehensive diagnostics. Enhanced control mathematics enables ongoing developments of Reishauer grinding technologies.

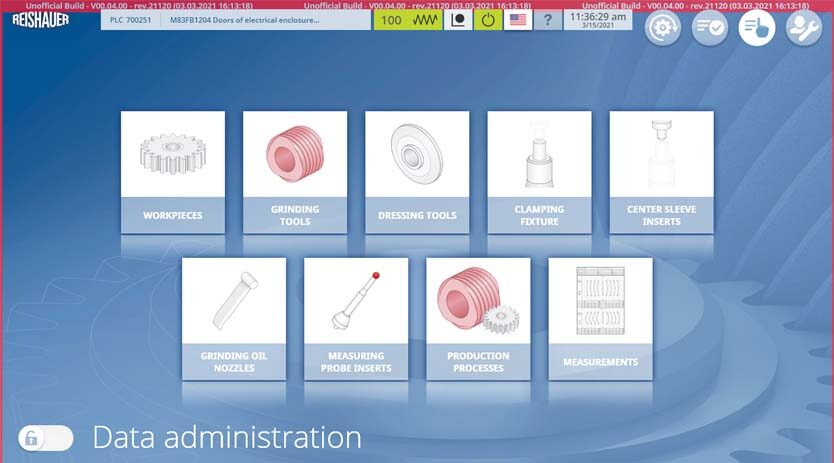

Reishauer Software Platform (RSP) Touch Screen CNC Control Technology

The scarcity of skilled operators demanded a rethinking of the machine’s operating design. Hence, the critical design criteria of the new RZControl were its user-friendliness. Easily understandable icons guide the user through the setup process. The Reishauer Software Platform RSP simplifies operation and process design considerably, reduces potential errors, and increases efficiency with modern database technologies encompassing tooling, workpieces, and processes. The control automatically generates machining proposals based on sophisticated calculation models during data input. The RZDesk option enables grinding programs on the PC, which can be transferred to the machine even during a running operation. While setting up the grinding process, the grinding time and number of parts per grinding wheel width are calculated, including for low-noise and optimised shifting. Operating equipment needs to be recorded only once and is available on a database, both on the machine control and the RZ-Desk option.Making Gear Grinding Transparent with Reishauer’s ARGUS Monitoring System

The ARGUS process monitoring system controls the dressing and grinding intensities by applying real-time data processing and tested algorithms. “Grinding and dressing intensities” are process- based force models to calibrate the grinding and dressing forces to interpret and control the process. The force models encompass the characteristics of the cutting zone, the cutting kinematics over the changing grinding wheel diameter, the variation of the wheel’s RPM, and the variable lever ratios depending on the wheel‘s position to the axial location of the bearing. The force calibration allows setting narrow limits for evaluating the process, which, in turn, offers the user a high- resolution error evaluation. For example, based on this evaluation and the set boundaries, workpieces of faulty prework are automatically removed.

Furthermore, the ARGUS system directly correlates grinding intensities and measurement data from the CMM. The gear grinding machine can produce far more parts per unit of time than a CMM machine can measure. Hence, to date, users must rely on sample measurements. However, once a few samples are approved, the ARGUS monitoring system is suitable for 100 percent in- process measurement, leading to zero-error production.

As the system offers traceability of each ground workpiece and off-machine data storage options, this allows new insights into the machine capability and KPIs of the processes. This system uses adaptive strategies for grinding and dressing, allows better usage of potential process parameters, and improves tool life, all of which carry significant economic benefits.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.