Belt drive solutions

By Staff Report October 9, 2024 6:28 pm IST

Belt drives are low maintenance, energy-saving, and versatile. N K Industrial Traders offers premium Optibelt solutions for addressing the challenges of poor-quality belts and providing reliable performance across various sectors.

For transmission of Mechanical power, speed & torque, the OEM industry relies on drive systems like – Gear, Chain, VFD, Couple & Belt. Amongst all, Belt Drive proved to be energy efficient, low cost, low maintenance and easy to access. Belt drives tend to be the first choice for most of the applications ahead.

Advantages of Belt Drives –

Belt drives are simple, low cost and do not require in-line shafts.

• They help to protect machinery from overload and jam, dampness, and isolate noise, friction, and vibration.

• They do not need lubrication and maintenance during service life.

• Belt drives are a simple way to bridge greater distances between two shafts.

• Frictionally operating belts such as Ribbed belts / V-belts also offer natural protection from overload. In contrast to gear drives, overload causes the belt to slip temporarily through sliding slip. This protects the transmission from major damage.

• Positive belt drives (Timing Belt) help to overcome all limitations of gear & chain drive. It has a dominant role in the motion control of Automation Equipment. It helps them to achieve precise positioning accuracy.

• Belt drives produce less noise as they utilise soft rubber belts to engage with pulleys rather than relying on metallic teeth. This enables the transmission of high rotational speeds, with minimum friction, noise, and vibrations in mating parts, which remains the root cause of most wear and tear.

• Causes minimum losses in user / PLC malfunction and machine accidents. It protects the headstock investment parts with the lowest recovery time & cost for belt replacements.

• Apart from rotary drive systems, belt drives have a unique role in linear drive systems. It serves as a complete solution against the limitations of rack/pinion, lead screw, and ball screw.Challenges

Belt drives are used in all industrial sectors. Due to the low cost of belt drive, they do not receive much attention, but the users are not aware that due to the failure of the drive system, there are many unfathomable losses. The energy loss is huge, leading to a loss of productive time and many hidden costs.

German technology machines are widely used in India. The machine is considered old and outdated when the user observes multiple belt failures and cannot diagnose the root cause. After the Covid pandemic, getting spare parts from abroad has become difficult. This has added to the loss of machine time.

Importance of good quality belt

Even if other parts of the belt drive like Pulleys, shaft locks etc are good, the poor quality of the belt will lead to major issues for users. The Inferior belts are affected even by ambient conditions leading to ageing belts and the efficiency of the drive goes down, including timing.

The solution from the expert – N K Industrial Traders

N K Industrial Traders are authorised distributors for Optibelt Germany. For Belt Drives, provide design consultancy, precise in-house processing, and energy-efficient solutions tailored to meet customer needs. This is backed by skilled staff, advanced service tools, and a robust inventory. They operate across many sectors, such as SPMs, robotics, automation, the printing industry, process equipment, etc.

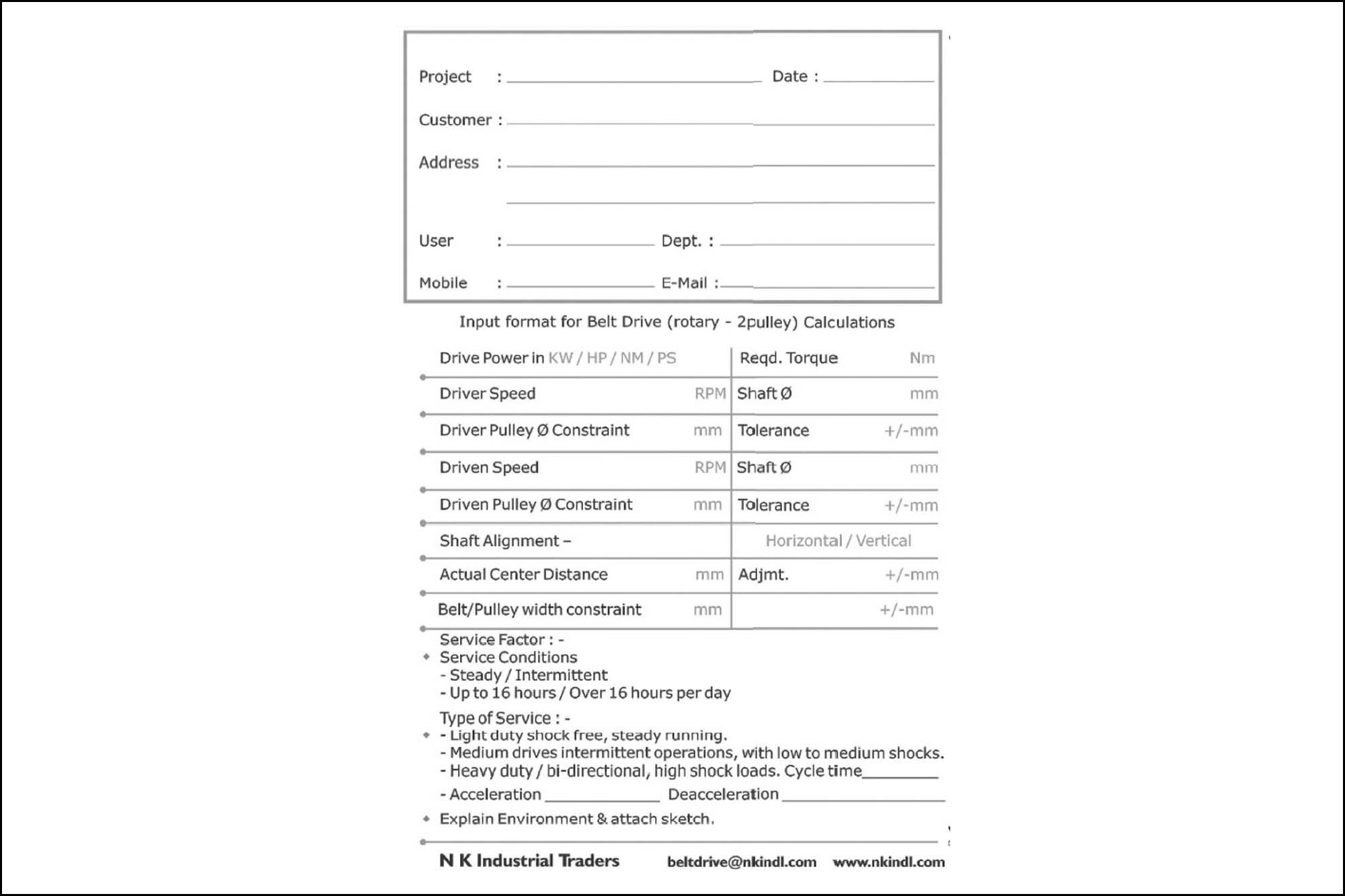

Product selection process for new application

While designing any new equipment, the selection process begins with theoretical mechanical calculations. An entire application is required for calculation in software inputs.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.