Wear-resistant sliding: New industrial profiles made of plastic from igus

By OEM Update Editorial November 11, 2017 2:48 pm IST

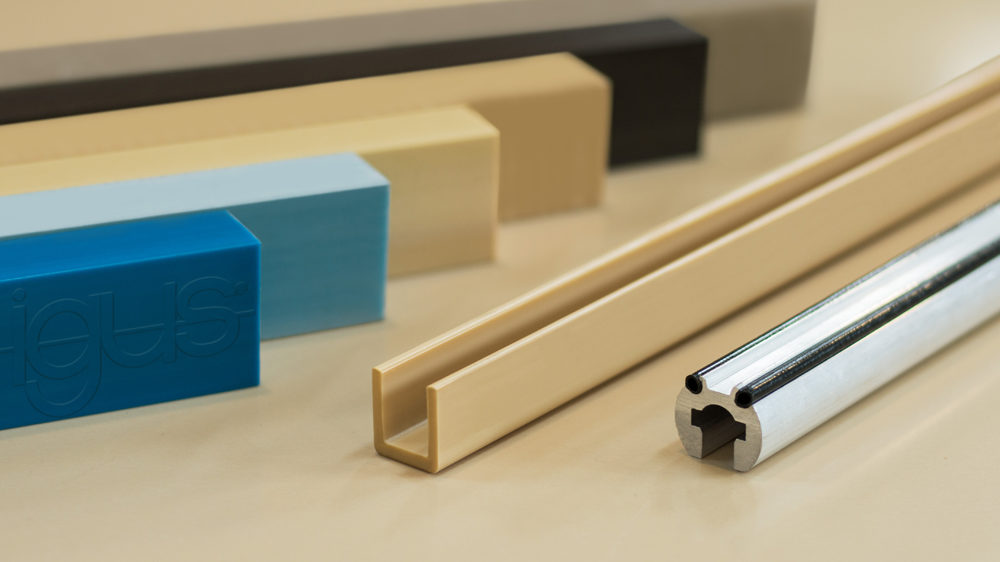

Customer-specific components made of various iglidur materials can be used quickly and in many different ways

In order to enable even more efficient production, the motion plastics specialist igus has expanded its range of bar stocks. This enables the ordering of industrial profiles designed to individual specifications made from the proven iglidur materials. When extruding the final form, the user saves costs for machining and material.

In plastic processing the production of components by injection moulding, especially for plain bearings, is not calculated by the quantity. For this reason, igus has been offering its iglidur materials as bar stock for mechanical finishing for several years. For even more freedom in design with the lowest possible costs, customers can now also obtain extruded profiles made of iglidur materials. “Based on our iglidur materials, we can implement a wide variety of profile geometries according to the requirements of our customers,” explains Ansgar Clemens, head of iglidurbar stock business unit at igus. “In this way, our customers receive their plastic solutions directly in the desired form, need less processing, and thus save time and money.” Examples of geometries are, for example, U-shaped or square profiles or half-shells or tubes made of iglidur. They are used as sliding rails, guide rails or wear profiles in a wide variety of industries, from machine and plant engineering, and the beverage and food industry including the textile industry.

limits for your creativityAll iglidur bar stocks – whether round bars, plate materials or profiles – are made of the iglidur plastics for movement, which are optimised for friction and wear, and are extensively tested in the igus laboratory. They do not have to be lubricated and are therefore maintenance-free.

If desired, special parts made of bar stocks can be procured within a few days via the ‘speedicut’ service. The submission of a 3D model or a 2D drawing will suffice, whereupon the components are manufactured and supplied directly by igus.

For more details, visit www.igus.in

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.