Wave Spring Technology: Merits & Values

By OEM Update Editorial October 7, 2020 4:37 pm IST

Smart tool for design engineers to create compact, light weight, cost effective products and solutions.

One of the key aspects of advanced design thinking is to design and manufacture products considering reduction in size, weight, raw material usage, while providing similar or improved performance, quality and reliability.

Wave Spring Technology is one such proven concept to meet the above mentioned targets.

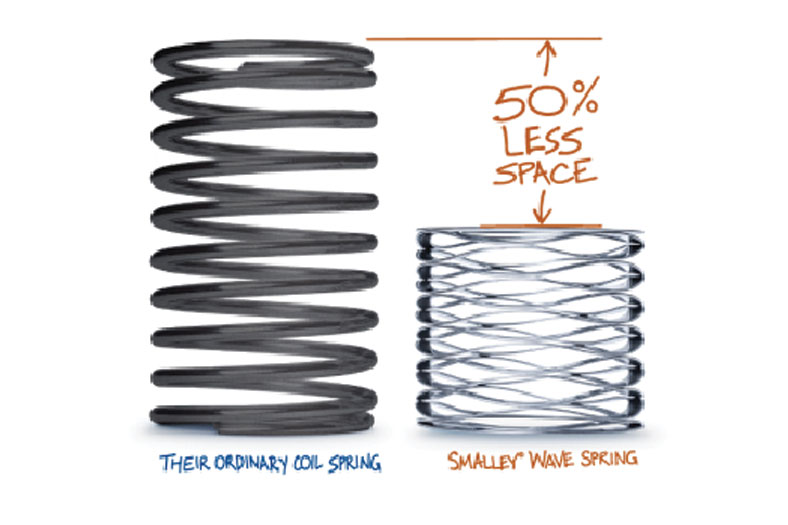

Merit 1: Design: Smalley’s Crest –to- Crest Wave Springs provides the same spring force and deflection with 50 percent of the height compared to conventional coil springs. This enables the industry to design and manufacture more compact, light-weight assemblies with lesser raw materials.

Merit 2: Manufacturing Process: Single-Turn Wave Springs, often used for taking of tolerances or applying a preload are manufactured utilising Smalley’s unique edge winding process. Coiled, not stamped like traditional wave springs provides a spring that has circular grain structure. Coiled Wave springs provide more accurate, repeatable load when compared to wave washers made of conventional stamping process, made out of sheets. The stamped wave spring, experiences fatigue, prior to the end of the life of the assembly thus leading to poor performance.

Engines, gearboxes, transmissions, brake systems, clutch systems, connectors, switches, motors, steering systems, actuators, valves, pumps and mechanical seals are some of the potential applications of Wave Springs to provide a consistent linear spring force and ensure greater sealability, safety and minimising maintenance down time.

Bearing Preload

What is bearing preload?

Ball bearings, composed of multiple parts working together as an assembly, are designed with clearances that permit freedom of motion. Clearance is not necessarily a result of manufacturing. Precision – bearings may be designed with greater clearance to accommodate higher axial loads or minor axial misalignment. As clearance and manufacturing tolerances stack up, a bearing assembly will begin to experience axial and radial play.

Bearing preload is the process of adding a sustained axial load, independent of external loads, to the bearing. An axial preload ensures constant contact between the ball complement and bearing races reducing or eliminating both modes of play.

Merits & Benefits of bearing preload• Enhance smooth running of bearing.

• Reduce friction and wear.

• Reduce noise, vibration and harshness

• Helps energy conservation

• Reduce maintenance down time.

• Reduce maintenance costs.

• Improve plant equipment productivity and reliability.

• Improve manufacturing accuracy.

Contact:

Mr S M Kanakaraj,

Smalley India Representative

india@smalley.com, raj@mark-consultancy.com

Mobile: +91-8939880655, 9444376957

www.smalley.com, www.smalley.co.in, www.mark-seals.com

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.