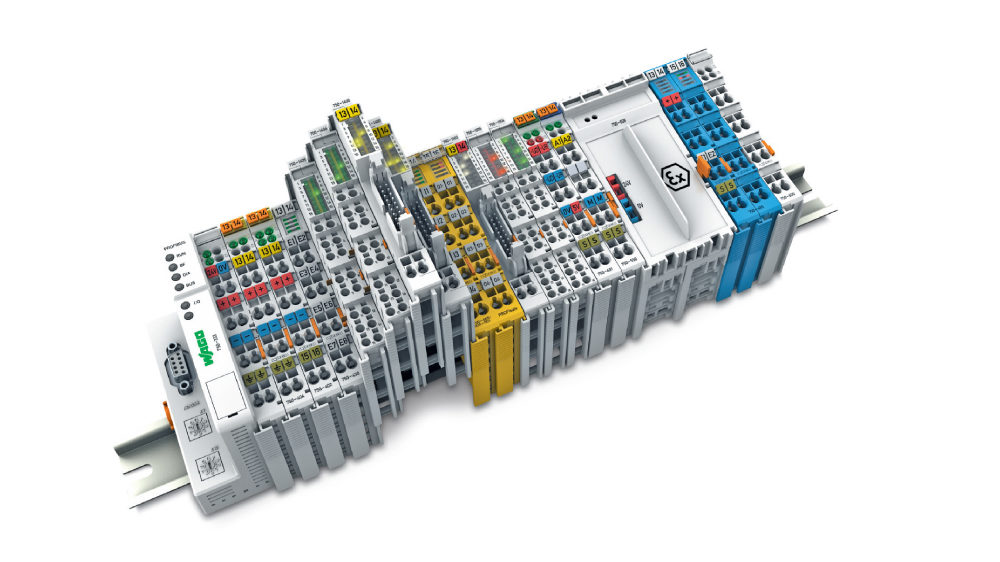

WAGO-I/O-SYSTEM 750: One system for every application

By OEM Update Editorial April 11, 2018 3:46 pm IST

As the leader in screwless interconnect and electronic interface technologies, WAGO developed the first finely modular, fieldbus-independent system in 1995. To this day, our steadfast commitment to innovation and versatility enables us to continue setting new standards in usability, performance and reliability. A compact design combined with the highest quality standards has made the WAGO-I/O-STSTEM one of the world’s most successful decentralised I/O systems.

WAGO offers programmable controllers in a wide variety of performance classes for performing any automation task. And, they can be used for both centralised and decentralized applications. For decentralised control tasks, the WAGO controllers can be incorporated into the most prevalent fieldbus networks and they record all field signals via I/O modules.

WAGO’s IEC 61131-3 programmable controllers perform a variety of automation tasks, while providing all the benefits of standard PLC technology (e.g., strength, stability, reliability and near-high constant uptime).

Direct connection to numerous and varied I/O modules that are part of the WAGO-I/O-SYSTEM 750 enables a large number of applications to be created. With performance and capabilities extending from the fieldbus controller to the PFC100 and PFC200, WAGO’s controllers provide scalable memory and speed along with a variety of interfaces and communication protocols.

WAGO’s controllers are powerful solutions for a wide variety of applications ranging from industrial and building automation to measurement and data collection. They easily integrate into existing IT structures, providing a link between real-time process data and IT applications. The controllers ideally combine real-time requirements with IT functionality. They support MODBUS TCP and ETHERNET/IP for use in industrial environments.

HTTP, SNTP, SNMP, FTP and other protocols simplify integration into IT environments. Integrated Web pages and Web-based visualisation provide IT applications with real-time process data.

A large number of library functions are available to support both software/hardware interfaces and an integrated file system. With more than 500 different modules, the versatility and flexibility is so great that virtually every requirement in a wide range of industries is covered.

Industrial AutomationA wide selection of I/O modules for various potential and signal types, as well as specialty functions, makes it possible to economically wire sensors/actuators – even in safety-related applications.

Building Automation

The broad portfolio allows for flexible, cellar-to-ceiling solutions with conventional I/O modules, standardized industry-specific fieldbus protocols and subsystems for typical applications in lighting, shading, heating, ventilating and air conditioning (HVAC) and more.

Marine and Onshore/Offshore Automation

International approvals coupled with industry-specific features permit use in shipbuilding and other harsh sectors. Addressing industry- and operating environment-specific requirements has enabled use on marine diesel and in the EMC-sensitive area of a vessel’s bridge. Because the requirements are significantly greater for immunity to interference or emission of interference and mechanical performance in these sensitive areas, the system can readily meet the needs of other industries.

Process Automation

Even under the harshest environmental conditions, use is possible with special approvals. Potential hazardous location applications include oil and gas production, the chemical industry and power generation. The WAGO-I/O-SYSTEM can be installed in Zone 2/22 with its intrinsically safe I/O modules making it possible to connect sensors/actuators in Zones 1/21 and 0/20.

For more information,

visit www.wago.com

and email at info.india@wago.com

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.