THE PRODUCTIVITY BOOST HIDING IN YOUR HYDRAULIC OIL

By OEM Update Editorial July 20, 2020 3:08 pm IST

Hydraulic lubricants the key to unlocking total cost of ownership savings

Ask any technical manager of a plastics injection moulding plant what their key challenges are, and productivity will no doubt be at the top of the list. To remain competitive, most must run their manufacturing highly efficiently in a 24/7 operation. There is no time for machine breakdowns and, if one does occur, often it’s blamed on a mechanical failure rather than poor lubrication.

Lubricants play a vital role in helping to extend the life of plastics moulding machines. Indeed, in hydraulic injection moulding, the hydraulic oil is the lifeblood of the machine. Its primary purpose is to transmit power mechanically throughout the system. In so doing it is exposed to high pressure, fluctuations in temperature and various contaminants, such as water and air. This means that a good hydraulic oil should be able to cope with typical application challenges such as wear, corrosion, oil leaks, fluctuating temperature, oxidation and thermal breakdown, and build-up of varnish and sludge that could lead to blockages and malfunctioning valves and filters.

Investing in high quality hydraulic oil may not seem like a top economic priority for a plastics production plant. Hydraulic oil is a fraction of the maintenance budget, but the long-term savings can be significant. When evaluating the effect of quality lubricants, consider total cost of ownership (TCO): the total amount spent on industrial equipment, including the cost of acquisition and operation over its entire working life, including costs of lost production during equipment downtime.

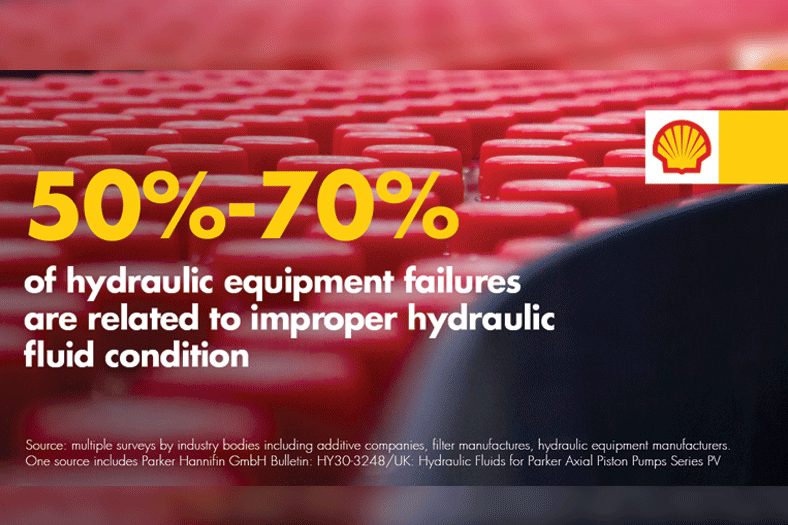

“Multiple surveys conducted by hydraulic equipment manufacturers and other industry bodies have shown that 50 percent to 70 percent of failures in hydraulic equipment are linked to oil quality and oil cleanliness,” says Praveen Nagpal, Chief technical officer at Shell Lubricants. “To be more productive and cost effective, customers have to choose the right hydraulic oil and keep it clean and cool to enable their equipment to run continuously.”

Shell developed its Tell us range of hydraulic oils to meet the demands of hydraulic systems, offering protection against wear, oxidation resistance, thermal stability, hydrolytic stability and filterability. First introduced in 1947 to inhibit rust and oxidation, over the past 70 years the formulation of Tell us has been enhanced and improved to match changing hydraulic system design and customer needs.

More than 200 scientists and lubricants engineers are dedicated to developing innovative lubricants technology at a variety of Shell Lubricant research centres throughout the world. As the process of creating new formulations is highly complex, Shell works closely with leading original equipment manufacturers (OEMs), to understand the needs of equipment and performance requirements.The latest addition to the Shell Tell us range – Shell Tell us S2 MX – took 10 years to develop. Shell Tell us S2MX is approved by various OEMs including Ferromatic Milacron, Windsor, Toshiba, Husky, Engel, Haitian and others, thus helping injection moulding plantsto manage inventory for all their machines. It exceeds requirements of the Bosch Rexroth Fluid Rating List RDE 90245 offering increased productivity, with extended oil life and outstanding system efficiency.

For instance, Hamilton Housewares Pvt Ltd, a leader in houseware products and having presence with major brands including Milton, Treo and Claro in over 80 countries has been running Shell Tell us S2 MX on its injection moulding machines at Sidcul, Haridwar plant for the past two years. Before this, Hamilton Housewares had been using Shell’s last generation Tell us S2 M hydraulic oil for eight years.

Another addition to the Shell Tell us range – Shell Tell us S4 VE, a gas-to-liquid (GTL) based hydraulic oil offers up to 10,000 hours TOST life estimating expected oil drain interval of 40,000 hours for plastic injection moulding machines. The product offers greater equipment reliability, reduced maintenance spends, superior energy efficiency and outstanding system efficiency.

In addition to the right lubricant, Shell offers services to support customers in helping to reduce machinery downtime and maintenance costs. These include LubeAnalyst, a means of monitoring the oil quality in their hydraulic systems to help identify any potential problems at an early stage, and LubeExpert, a technical consultation service that offers application-specific knowledge.

Selecting the right lubricant together with harnessing support from these specialist technical services from Shell Lubricants is a critical step in improving productivity and helping to realise significant TCO savings.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.