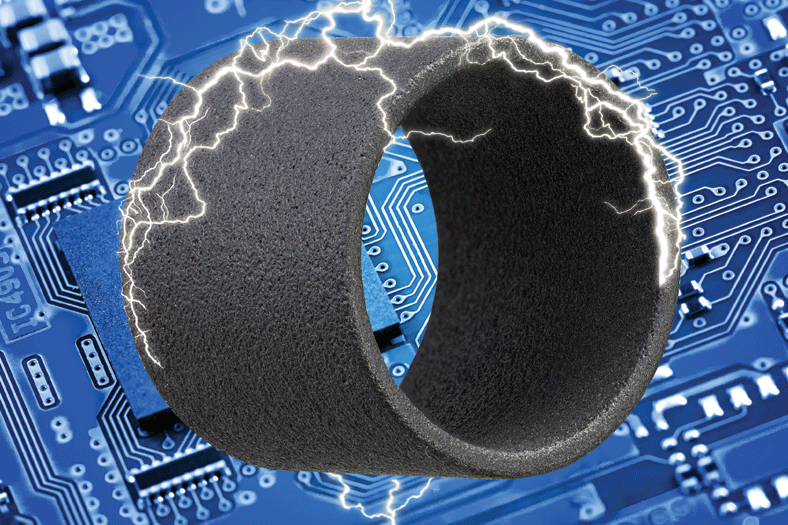

New igus SLS material for electrostatically conductive wear-resistant parts from the 3D printer

By OEM Update Editorial July 9, 2020 12:09 pm IST

Lubrication-free tribo-polymer iglidur I8-ESD enables the cost-effective manufacture of durable special parts with no minimum order quantity

For safe and reliable production in the electronics and semiconductor industry, components are required that have electrostatically conductive properties. This is because even a small electric shock can destroy expensive production lines. igus has now developed a new stable material for the SLS method so that users can make their wearing parts with ESD properties flexibly and cost-effectively. The lubrication-free special parts made of iglidur I8-ESD can be printed and shipped within just few days.

iglidur I8-ESD convinces with high wear resistanceThe igus tribo-polymers undergo numerous tests in the igus 3,800 square-metre test laboratory. Here a pivoting test showed that the abrasion resistance of a sintered iglidur I8-ESD wear-resistant part is twice as great as that of a PA12 sintered component. iglidur I8-ESD was also convincing in a linear wear test. igus currently offers iglidur I8-ESD in the webshop as SLS powder for processing in the customer’s own facility or for manufacture of a component in the igus 3D printing service. For the latter purpose, the user can simply send the STEP file for the part required to igus.

For more details, visit: www.igus.in

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.