Material and design enhancements drive EV innovation

By OEM Update Editorial November 13, 2018 3:44 pm IST

When Benjamin Franklin proved lightning and electricity were one and the same using a kite, a key and a strong hypothesis, this force of nature became a prime candidate for experimentation rather than simple parlor tricks. More than 100 years later, Thomas Edison perfected the incandescent light bulb and made electricity affordable for all.

Electricity continues to power innovation today, especially within the automotive industry where manufacturers are grappling with the challenge of making vehicles more fuel efficient. Advancements in electrification and lithium-ion batteries are driving serious growth in the all-electric vehicles (EV) and hybrid electric vehicle (HEV) space.

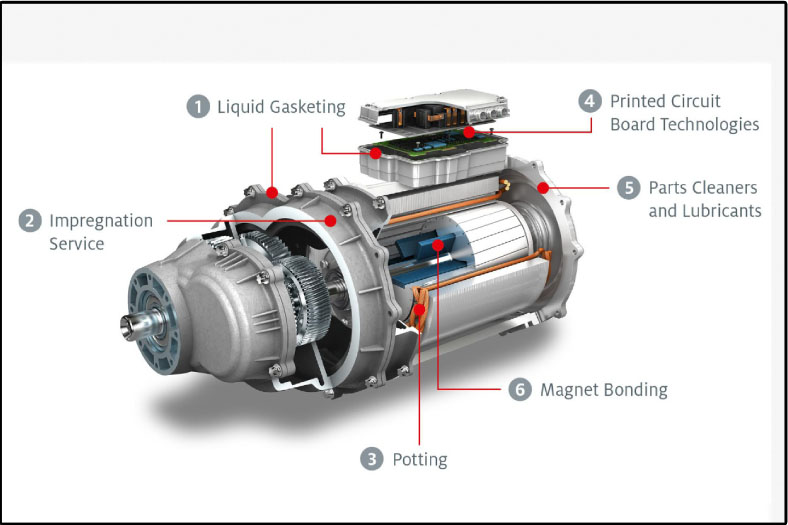

Henkel’s leadership in the automotive sector with a broad range of advanced automotive materials for e-mobility applications, including thermal control and novel adhesive solutions for the battery system and vehicle body are driving the automotive e-mobility ingenuity.

Innovation in EV

Advancements in electrification and lithium-ion batteries are driving serious growth in the EV and HEV space. For the 2017 model year, at least 13 new EVs and HEVs were announced, which shows a great deal of optimism. In fact, an EV was named 2017 North American car of the year at the North American International Auto Show. This, in part, is due to battery packs coming down in cost and weight while increasing in range and power. The result is more affordable electric vehicles that are capable of extended performance.

In fact, concern over ‘range anxiety’ is waning. Drivers worried about having sufficient battery charge to manage their daily driving are increasingly satisfied by today’s electric vehicles that boast ranges exceeding 200 miles per charge.

EV and HEV growth is directly related to the advances in lithium-ion batteries, especially the technology of the battery cell itself and for the assembled battery pack. This has all been made possible by material and design advancements.

A lighter, quieter ride

The efficiency and range of the battery is not only about Li-ion technology, but also highly dependent on the vehicle weight. Lighter vehicles require less power to propel them, which generally translates to longer range capability and extended battery life. As a top innovator of vehicle body assembly materials, Henkel has engineered a complete line of TEROSON structural inserts that reduce heavy metals in vehicle construction, facilitating a lighter overall structure for greater energy efficiency and crash protection. TEROSON structural adhesives improve stiffness and durability of connections and enable the use of multiple materials for crossbeams, pillars, joints, longitudinal bars and other planar metals for lighter structures with enhanced safety. As the battery is integrated into the vehicle body, there is a requirement for crash prediction, along with durability and fatigue performance of the entire system. In addition to supplying advanced materials, Henkel’s engineering and design teams also provide predictive performance data and aid in the development of lightweight designs.

Advanced damping, sealing and absorbing materials reduce noise and vibration for a quieter driving experience. Henkel’s TEROSON range of NVH products not only block air in the cavity and flanges with baffles and tapes, but also treat structurally-transmitted noise by shifting frequencies and converting kinetic energy into thermal energy with stiffening and damping solutions.

Conductive coatingsAdvancements in the chemistry of conductive coatings for Li-ion batteries have led to performance improvements that help to extend range and life. One such advancement is Henkel’s BONDERITE S-FN 15000 conductive and protective organic coating for battery and ultracapacitor applications. It enhances electrical conductivity, provides corrosion protection and chemical resistance.

Amping up reliability and efficiency

The power storage system requires advanced materials to effectively control the heat generated during operation and to keep external pollutants from contaminating the internal battery structure. Henkel’s award-winning BERGQUIST brand’s thermal interface materials (TIMs) are used extensively throughout the lithium-ion (Li-ion) battery structure to alleviate the increasing thermal load produced by modern, high power density Li-ion batteries. BERGQUIST GAP PAD and SIL PAD thermal interface materials are soft, compliant thermally conductive pad-based materials most often incorporated in on-board charging, battery management and inverter systems between heat-generating components and the heat sink or chassis. BERGQUIST Gap Fillers are liquid-based TIMs that are ideal for complex architectures and operations that require high automation and throughput. Applicable to any thermal transfer point within the Li-ion battery structure, liquid gap fillers are most frequently employed between battery modules and the housing, between battery cells, as well as on powertrain busbar designs and in power conversion systems.

Throughout their lifetime, electric vehicle batteries are exposed to rain, dust, automotive fluids, and even salt spray in colder climates. Chemicals and particles from these elements can harm battery circuitry, potentially causing failure. Keeping the entire battery system free from contaminants that can impact performance is essential to long life and reliable operation. Here, Henkel’s gasketing and sealing materials deliver a strong, tight barrier against environmental pollutants. A range of LOCTITE brand adhesive sealants provide formed-in-place, cured-in-place or molded-in-place capability to protect battery integrity and enhance long-term reliability.

Sealing

Sealing also plays a very important role in the battery case assembly. Henkel’s robotically applied liquid gaskets provide options that give manufacturers flexibility. The newest product, LOCTITE EA 5470 liquid foam gasket enables more efficient and effective battery pack design. It is a soft, low compression set gasket that is UV cured. It’s a rapid-set material and can be applied prior to assembly, which reduces work-in-process.

At both the cell and battery pack level, Henkel’s innovative technologies add reliability and extended life with sealing, cell enhancement and thermal control with minimal weight to keep electric vehicles moving forward. In addition to e-mobility solutions, Henkel’s automotive specialists can speak to any of the engineering services and more than 100 materials the company is successfully employing in automotive production for ADAS, power conversion, lighting, infotainment, displays, and crash and safety systems, among others. These include: TEROSON structural solutions, LOCTITE adhesives, underfills, encapsulants, coatings and solder materials, TECHNOMELT low pressure molding and BERGQUIST thermal management materials.

Authored by

Barun Bharadwaj,

Business Director – Transport & Metal,

Henkel Adhesives Technologies India Private Limited

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.