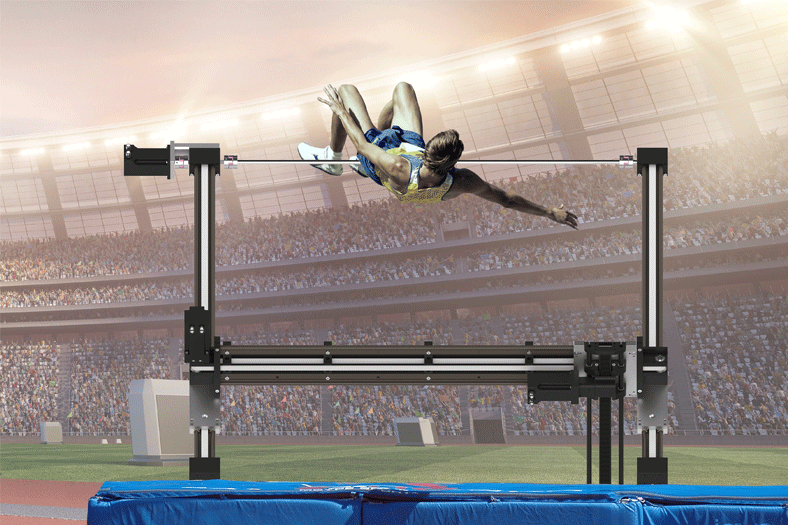

Low-cost process automation with lubrication-free drylin linear robots from igus

By OEM Update Editorial January 9, 2020 4:02 pm IST

Simple, precise, fast processes: these are the requirements of Cartesian robots. They are used for such things as pick-and-place applications, sorting systems, and medical technology. igus has now developed a linear and room linear robot for large workspaces. The two new kinematics systems allow users to move up to five kilogrammes. Both linear robots are available directly from stock. They can also be customised to suit the customer application in question, with no minimum order quantity. For years, Cartesian robots have been the means of choice in automation technology. They allow users to complete their tasks quickly, easily and cost-effectively. All that is required is a little bit of programming effort. igus’ lubrication-free linear axes are developed in several stages.

Low-cost automation with lubrication-free linear robot solutions

The two linear robots consist of pre-configured linear modules, aluminium linear axes, NEMA stepper motors, and encoders. The new line robot can transport loads of up to 50 N in a workspace of 800x500mm at a maximum speed of up to 1 m/s. “The investment risk for the line robot is manageable, so that our automated pick-and-place applications for assembly tasks pay for themselves in less than six months. This means that decision makers have a low level of risk,” says Alexander Mühlens, Head of Automation Technology at igus. The new room linear robot is a good option for more complex tasks. It can transport loads of up to 50 N in a workspace of 800x800x500mm at a maximum speed of 0.5 m/s. Two ZLW toothed belt axes and one GRR gear rack axis ensure precise guidance and lubrication-free operation.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.