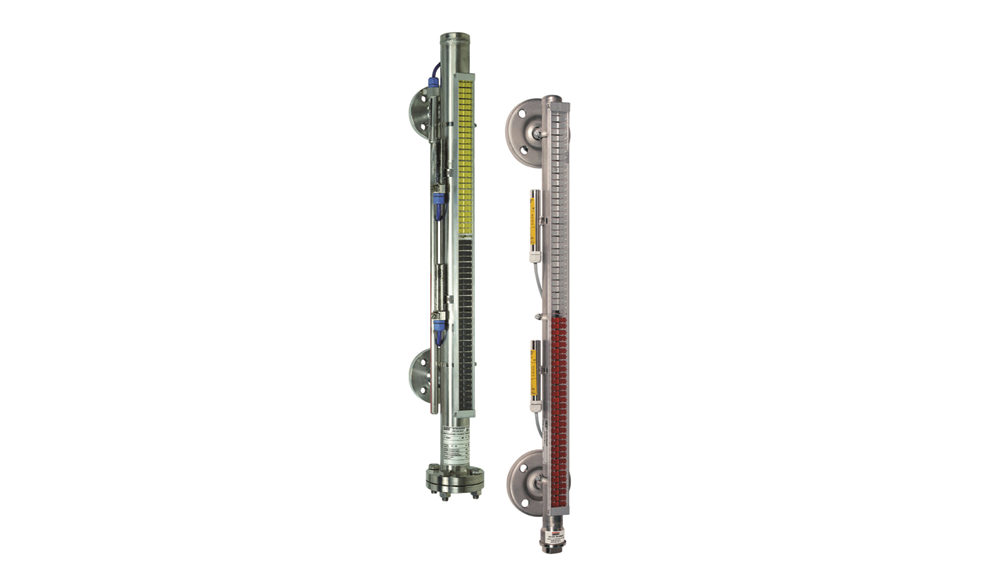

Level indicators

By OEM Update Editorial November 12, 2017 12:47 pm IST

Visual level indicators combine up to three functions in one instrument: Level indicator, level switch and level transmitter. The display that can be read even over large distances works without energy and automatically as a result of the physical law of liquids in communicating vessels. The WEKA visual level indicators are characterised by their compact design and the wide range of applications.

Wide application range

Operating pressures can range from a vacuum up to 500 bar as well as calculation pressures for the float standpipe up to the nominal pressure PN 630. Liquid densities over 0.27 g/cm3 as well as a temperature range from 77 K to 673 K (-196 C to 400 C) allow use in applications for cryogenic liquid gases as well as in water hydraulics and steam boilers. Hermetically sealed floats for condensing media are available up to a maximum operating pressure of 320 bar.

Flexibility through choice of suitable materials

• Standard materials: 316/316L 1.4435/1.4404, group A4 stainless austenitic steel.

• Other possible stainless austenitic steels: 304/304L 1.4301/1.4306, 1.4571, 321, 1.4541.

Energy-free, automatic operation

The WEKA visual level indicator is ideal for the commissioning of systems. The display works without energy and automatically as a result of the physical law of liquids in communicating vessels. Independent of a controller – and thus also independent in the event of a power supply failure – visual level indication on site is ensured.

Excellent readability

The wide, red- and silver-coloured flag indicator system is easily and clearly readable, even from over large distances. The fully transparent flag indicator system made of polycarbonate (PC) also ensures readability from the side. The liquids, which are not always unproblematic and sometimes also hazardous, are safely enclosed in the dense and pressure-tight float standpipe and separated from the indicator.

As described, WEKA visual level indicators offer the ideal solution for almost all operating conditions. For most applications, you will find a suitable device from our standard program. Again and again, however, customised solutions are also required for special operating conditions. Many designs can, for example, also be used in hazardous areas according to ATEX or IECEx. (ATEX is a widely used synonym for the ATEX guidelines of the European Union) The designation ATEX is derived from the French abbreviation of Atmosphère Explosible (explosive atmosphere).These instruments can thus also be used in potentially explosive atmospheres.

Applications

Explosion-proof plants, mechanical and plant engineering, water management, ship building, energy, space, and research.

Contact:

Toshniwal Hyvac Pvt Ltd,

267, Kilpauk garden road

Chennai – 600010

Tele: +91-44-26445626/8983

Email: sales@toshniwal.net

www.toshniwal.net

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.