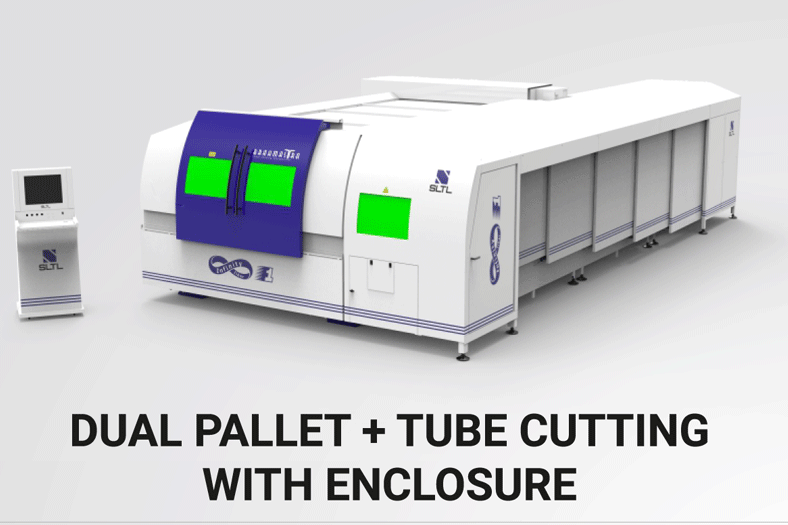

Infinity F1 for 2D sheet metal cutting and tube cutting

By OEM Update Editorial January 9, 2020 3:39 pm IST

The market today is flooded with fabricators who wish to make a mark in the manufacturing industry by offering superior quality, productivity, and affordable operating cost. To achieve these standards, SLTL Group has developed Infinity F1, a fibre laser cutting system with Modular Product Architecture (MPA). This system is designed to provide the best throughput with effective and efficient operations.

Infinity F1 is the best-selling product in the market and has been chosen as the industry’s favourite since its inception. With MPA, the machine can be integrated with different modules to perform productive operations and achieve new tasks. Therefore, with MPA, the machine can be upgraded as per future needs. Infinity F1 can do 2D sheet metal cutting as well as tube cutting. 2D cutting allows us to operate on various thicknesses and materials like aluminium, brass, copper, mild steel, galvanised iron, titanium, and stainless steel. With an adjustable four-jaw chuck system to hold the different tube shapes, it can process various shapes like circular, rectangular, triangular, and square. It is also equipped with a double servo motor for accurate movement of the tubes. This will help fabricators bring in variety into manufacturing. It is highly productive for micro, thick and thin cutting.

Equipped with features and options to perform numerous tasks, the machine is designed to meet the needs of speed, quality, and productivity. It can achieve a butter cut finish with integrated software and hardware and has a robust machine structure to ensure maintenance-free work. The in-house research and development team has created a complete system for fulfilling the demands of the industry.For more details,

visit: www.sltl.com

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.