igus launches its first catalogue range for intelligent plain bearings

By OEM Update Editorial May 8, 2020 3:57 pm IST

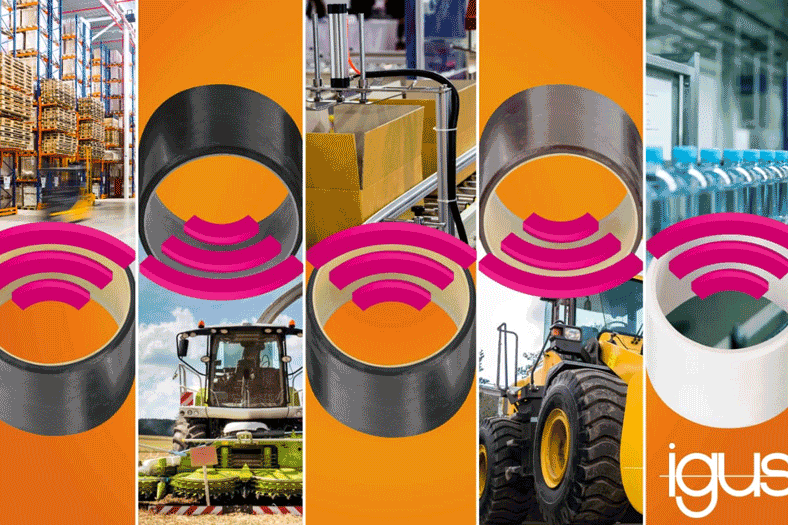

From forklifts to packaging machines, isense plain bearings provide information about their wear and warn in good time before the stoppage of plant or machinery.

Presented last year as a prototype, igus has now developed its first isense plain bearing series with five iglidur materials for predictive maintenance. Whether in the food industry, textile machines, forklifts or construction machines, with the intelligent isense plain bearings, users receive a durable and lubrication-free solution that provides information about their wear. Maintenance can be planned in good time and machine and system failures are prevented.

Wear-resistant parts such as plain bearings must withstand extreme loads in machines and plant. If one of these bearings fails, there will be big trouble. For this reason igus presented the first study of an intelligent plain bearing at the Hannover Messe 2019. The principle: technology integrated in the bearing detects wear in advance and gives the user a signal in good time when the wear limit is reached. Maintenance can be planned in advance, and unnecessary replacement and unplanned machine and system failures are avoided. After many series of tests in the 3,800 square metre in-house test laboratory, igus has now developed the first isense standard range for its lubrication-free iglidur plain bearings. “The catalogue range includes five materials with which we can cover a large part of highly stressed applications,” says Stefan Loockmann-Rittich, Division Manager iglidur Plain Bearing Technology at igus GmbH. The FDA-compliant material iglidur A180, which is specifically designed for use in the food industry, the heavy-duty bearing iglidur Q2E for use in construction machinery and agricultural engineering, the all-rounder material iglidur G, the endurance runner iglidur J as well as iglidur P210 as a specialist for pivoting and rolling applications are also included. igus offers all intelligent plain bearings in three dimensions each with an inner diameter of 20, 30 and 40 millimetres. Further sizes and materials will follow.

To connect the isense plain bearings, igus has four suitable cables with an oil-resistant and media-resistant PUR outer jacket, in four standard lengths of one to ten metres, in its portfolio. In addition, the user has the choice between two connector types. The sensors measured data can be integrated by the machine and equipment operators into their systems in different ways. igus offers three readout units for this purpose: either the user can manually read out all plug-in points, or install a control unit with a red/green display on the machine which provides information about the condition of the plain bearings. Another possibility is the connection to icom.plus. For this purpose a radio module sends the sensor data by wireless transmission to the communication module. From here, the integration of data to the IoT, cloud system or to the customer network is possible on a wire-bound basis. “The customer has the freedom to read the data in the way that suits him best,” explains Stefan Loockmann-Rittich.Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.