HeavyDuty encoders in crane and lifting applications

By OEM Update Editorial May 13, 2020 4:38 pm IST

Baumer Hübner has established the class of extraordinarily resilient and reliable HeavyDuty encoders and offers a broad portfolio. Manufacturers of cranes and hoists are among the most frequent users of such sensors. And for good reason: These applications are most demanding and here they can play to their strengths such as robustness, precision, resistance, and longevity.

Crane installations perform the hardest work day in and day out, often under harsh conditions. They withstand dust on construction sites, resist salt water and wind in ports, and are exposed to the elements and operate in hot summer as well as in deepest winter. Those who are not tough enough have no chance to survive. And what applies to the overall system also applies to its components, such as sensors monitoring speed and angular positions at drives or machine shafts — the rotary encoders. This is the reason why HeavyDuty encoders are installed in many crane systems and giant hoists.

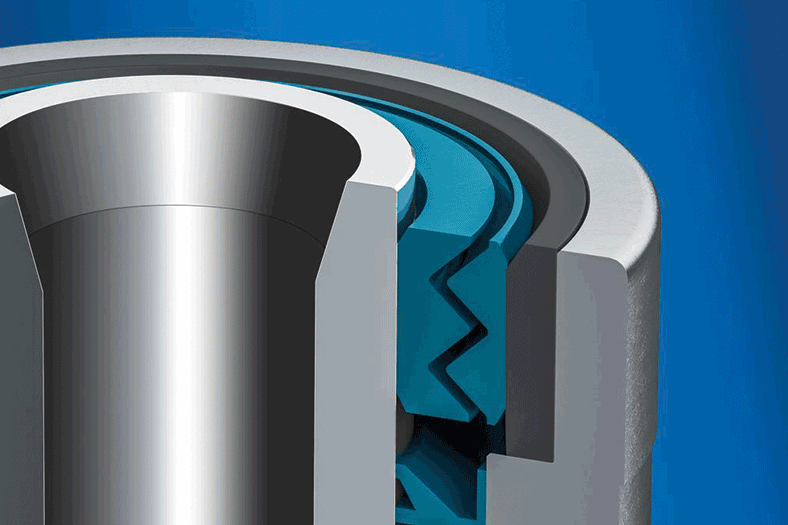

For many years, encoders at cranes and heavy hoists must withstand hard shocks, strong vibration or shaft load without losing their functionality. Therefore, mechanical robustness is key. Solid and largely spaced bearings at both shaft ends must compensate axial and radial loads; furthermore, all inside components must be protected by a shock and vibration-resistant design. HeavyDuty encoders must be immune to electromagnetic fields emitted by live, unshielded cables. Corresponding shielding of the encoder inside electronics must protect against destruction and prevent signal errors. Electrical insulation is also required for draining shaft currents.

Another important point is tightness. In view of the application environment of HeavyDuty encoders — marked by dust, dirt and moisture —protecting seals at critical, neuralgic points are a must: shaft and electrical connections. In parallel, seals are a good protection against corrosion by salt water or chemicals. Finally, their task is high-precision performance at drives and generators. Doing so calls for reliable delivery of precise signals, since even minor measuring errors may have significant, maybe even life-threatening consequences, for example when lowering down loads weighing several tons.There are various mounting options, whether as hollow shaft designs (through or non-through) cone shaft or solid shaft mount with optional EURO flange B10. If required, HeavyDuty encoders, speed switches and tacho generators can be combined in one robust, space-saving unit for receiving varied signal types all at once measured at one drive shaft. Large encoders such as HOG 16/22/28 by Baumer are used for maximum speed limit monitoring at drive shafts under most difficult conditions, such as in coal dust, salty air or in the burning heat of steel mills. With quick, energy-efficient lifting and positioning of loads weighing tonnes with millimetre precision, HeavyDuty encoders at crane installations and hoists provide users with the control information required to get the job done.

For more information, please visit:

www.baumer.com

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.