Connectors boost the efficiency of wind power plants

By OEM Update Editorial January 15, 2018 4:32 pm IST

More modularity, more flexible handling

Germany’s roughly 30,000 wind turbines currently produce a good 50,000 megawatts of electricity for households and companies. The expansion of wind energy both onshore and offshore is helping determine the pace and success of the shift in energy policy introduced at the beginning of the decade – a move away from nuclear power towards renewable energies and reduced energy consumption.

For installers and operators, profitability and efficiency are of paramount importance when it comes to site preparation, installation, operation and the maintenance of wind turbines. These factors determine the level of investment and operating costs (CAPEX/OPEX) – and ultimately determine the economic impact a wind power plant can provide. Plants which are down produce no energy, receive no feed-in tariffs, and leave their potential to generate revenue untapped.

With its innovative connection technology, the HARTING Technology Group is accompanying the transformation under way in the energy sector. Harting’s product portfolio ranges from single components through complete customer-specific solutions and digitisation strategies. The company’s offerings also include consulting and services, thus providing the basis for long-term, lucrative and secure investments in this sector.

As one of the world’s leading manufacturers of industrial connectors, HARTING has decades of experience in the development and use of connectors for an extremely wide variety of applications and challenges. Wind turbines are subjected to extraordinary stresses both onshore and offshore due to the particularities of the respective location, climate, corrosion and other environmental influences. Creating the foundation for maximum value retention of these systems takes optimal reliability, the best materials, high mechanical robustness of the components that are used, rapid assembly, optimal maintenance cycles and servicing that is simple to perform.

HARTING connectors help reduce the costs of erecting and operating wind turbines. Modular wind turbines are characterised by flexibility of design and rapid component switch-out. Connectors significantly increase the modularity of these facilities – and more and more wind turbines are being designed accordingly. The pre-assembly of individual units makes the modular concept possible. Components are quickly and easily joined together only at the final location of the wind turbines.

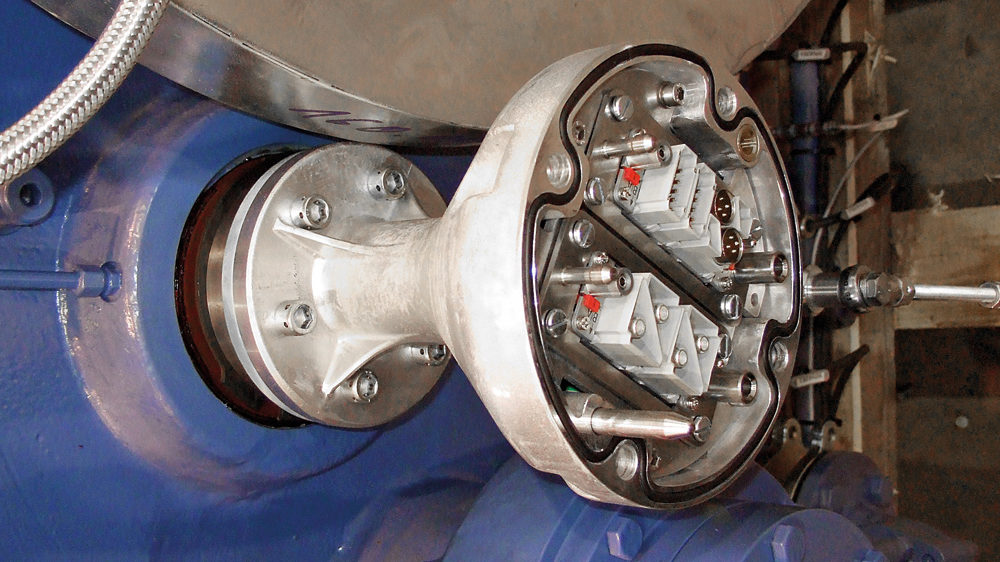

HARTING connectors are characterised by many advantages: using connectors to bridge wind turbines modules can limit the monetary and personnel costs accrued during installation and operation of wind turbines. A good example is connectors at the interface between the slip ring body and stationary nacelle. The slip ring is used to e.g. transmit the signals for the pitch systems that determine the angle of incidence of the rotor blades. A pluggable design – for example Han-Modular contact inserts and the Han-Modular hinged frame – offers many advantages over permanently attached wiring.

The slip ring can be replaced more quickly, thereby reducing downtimes and minimising revenue loss. In addition, if servicing is required, the slip ring can be replaced without intervention in the pitch system and without dismantling the connecting cables.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.