Reinstating the automotive sector with technology

By OEM Update Editorial January 9, 2020 2:56 pm IST

Automotive industry leaders discuss the visible growth in the automotive industry along with reaping the benefits of the emerging industrial trends with latest technologies.

Automation has been keying the industry to take leaps in automotive manufacturing. Adoption of indigenous manufacturing and latest technological innovations have nurtured the sector’s overall financial growth. However, with the invention of sophisticated technologies like automation, IIoT and 3D technology, among others, the Indian automotive industry is reaching new heights. With intensifying demand in the automotive industry, it is now imperative to have an uninterrupted supply.

Trends in automotive sector shifting with advanced automation

If you look at the history of automation in the automotive sector, the first areas that got automated were hazardous sectors like painting and welding. This has largely to do with reducing the hazards and number of people with a speed which is fairly well-settled now, as most of the painting/welding activities has been largely automated. The second aspect of automation is the line assembly and automation of assembly itself, where the product moves from station to station. On this note, Ramesh TK, CEO, Ace Micromatic Machine Tools Pvt. Ltd. says, “The work that needs to be done now is connectivity and data analytics. This data analytics is not from the market perspective, but from the management perspective, ratability or right from assembling and final dispatch; because they all come from the safety aspect, this is the area where automation is happening towards its end. We still need to have active involvement of automation in the designing perspective, as the designing remains to be a non-automated process largely. ”

The entire automotive system has been divided into subsystems, where you have transmission systems, cabin interiors, stylish dashboards and engines, among others. These systems are completely independent and easy to access. The design and tools that control the designs must be modular, as it supports the entire functionality of a vehicle. Babu further says, “With the mixture of modular tools and modular designs, we can obsolete the previous and existing car models quickly, whilst introducing the new car variants in minimum time frame. This further helps in rearranging the entire supply chain ecosystem for smooth delivery of new orders. This is the need of the hour and the entire automotive industry is transforming with this scheme in its own way.”

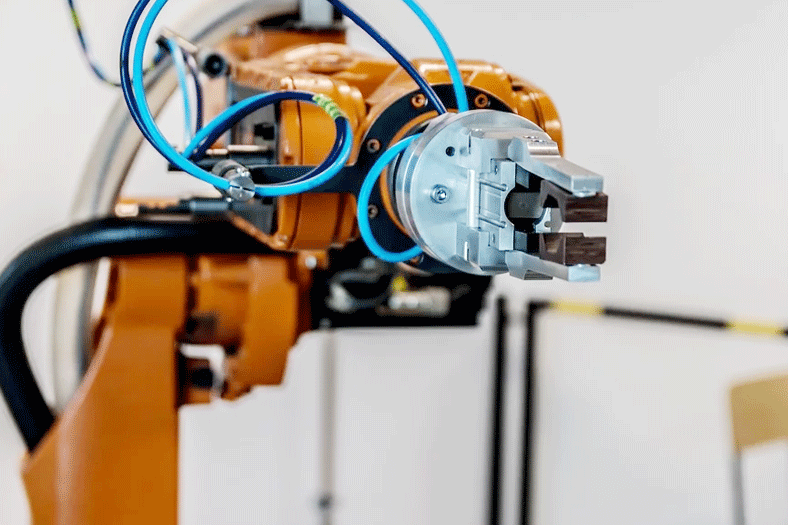

Automation also allows a common assembly line for different models to be managed by various sets of robots. The most important thing is to use a common assembly line for multiple models managed by different set of robots with least human intervention to ensure compatibility. The modular approach and common assembly line driven by tools and automation is helping the automotive industry to combat slowdown and ensure growth.

Elaborating on the capabilities of automation, Sameer Gandhi, MD, Omron Automation, India feels that the auto manufacturing sector is driven by varied KPIs like design and energy optimisation, finest asset utilisation, big data and analytics (connected supply chains and shop floors), worker and machine safety and zero-defect production, and has shown good adoption rates for varied automation technologies falling under the ambit of Industry 4.0, IoT and robotics.

One of the notable applications amongst these is the total traceability solution. It renders the ability to trace and verify the history, location, or application of an item by means of documented recorded identification. Having a close interface with IIoT, this solution holds lot of significance for the automotive industry.

Improving precision manufacturingOne of the major advantages of automation is that it is very durable with variability, which is not the case with humans. From the western perspective, automation is a basic necessity owing to the unavailability of required manpower. But India has surplus manpower, so automation has to be applied in ways where manpower is not affected.

Discussing the significance of the human factor, Ramesh asks if everything is mechanised, then what will people do and where will the PPP offer be applied? He says, “From the Indian perspective, we still have a large population that needs manufacturers to do certain manual content, which is the livelihood and also increases the PPP of our country. Whether it is the automation or mass manufacturing industry, the process of eliminating people must be stopped. In fact, we should update our manpower to automation. Everybody from the world is coming to India with the expectation to grow. We need to support that.”

However, according to Babu, “Precision in the automotive industry is driven by tools where human intervention has to be low. Different level of precision applies to different equipment. I would say that automation is a requirement born out of precision and human fatigue point of view.” With automation liberating some tasks, humans obtain more scope and freedom to focus more on higher-level and creative tasks that demand more complex skills, and for this a well-structured plan to evolve and upgrade their skill sets is also needed. Noting the same, Gandhi says, “Automation helps improve the precision and repeatability of a given task. But, the idea is to achieve the best harmony between humans and machines, between the power and precision of automation or robots and the problem-solving ability of humans to achieve greater productivity and achieve something which is beyond human capabilities.”

3D printing in automotive

3D printing is an absolutely different application with a different perspective, and today it is predominantly used for prototyping. It is said to be the best fit in certain areas, but it is yet to meet the requirements of the industry in terms of real application. 3D printing involves both design and manufacturing and is a different aspect of both, where an assembly or a component is completely resigned to a system.

Babu states, “We have executed several projects by redesigning fuel injection pump, hydraulic manifold, among others. Moreover, 3D printing has eased the assembling process by cutting down the requirement of 30 parts to almost 6. Still the composition of material and purchasing of adhesives and laser must comply with 3D printing standards to use them in an extended market. Predominantly, hydraulics used in block manifolds is delivered in 3D printing and in several automotives.”

To sum it up, usually, aftermarket and spares for automotive parts is a major market, while the repair market, especially for automobiles, is enormous. This is a market additive manufacturing, which is being added to the aftermarket for providing value-added services to consumers. Apart from these spares, especially for replacements in case of damage or fault, there is a budding market for customised components where consumers are also willing to pay a premium.

I think automotive designing still remains to be a non-automated process at large, and automation can reinstate designing with a single touch.

Ramesh TK, CEO, Ace Micromatic Machine Tools Pvt. Ltd.

Precision in the automotive industry is driven by tools where human intervention has to be low.

Sharadhi Babu, Chief Executive Officer, AXISCADES

The modular approach, automation, and common assembly line is helping the automotive industry to take leaps in industrial growth.

Sameer Gandhi, MD, Omron Automation, India

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.