Assembling automotive with precision lifting technologies by Binar Handling

By Staff Report October 9, 2024 6:22 pm IST

Binar Handling is helping automotive manufacturing with ergonomic lifting solutions that reduce physical strain and improve safety in manufacturing operations. They especially work to improve precision and smoothen the assembly processes for heavy and delicate vehicle components.

The automotive industry is constantly trying to improve efficiency, ensure worker safety, and maintain high levels of precision in production processes. As vehicles become more advanced, so does the complexity of their manufacturing. One of the key challenges automakers face is safely handling large, heavy, and intricate components on the assembly line. Schmalz, a leader in ergonomic lifting technology, offers a range of solutions designed to meet these challenges head-on, helping automotive manufacturers streamline processes and enhance productivity.

Modern automotive manufacturing handles engines, body panels, dashboards, and suspension systems, all presenting unique challenges. The repetitive lifting of heavy or awkward components can lead to physical strain and worker fatigue, often resulting in musculoskeletal injuries. These issues affect worker health and hamper their productivity, which reduces downtime and increases operational costs. Precision is needed when assembling high-value automotive components. Misalignment or damage during handling can compromise the quality of the final product. So, manufacturers have to adopt solutions for accuracy and safety.

Schmalz expanded its product portfolio with Binar Handling’s ergonomic lifting solutions, designed to meet the diverse needs of automotive production. The product range focuses on reducing physical strain, improving precision, and overall safety. The NEO 30 Control Handle improves Binar’s product line-up. This device converts subtle hand movements into precise lifting motions, allowing operators to control parts with minimal effort. NEO 30 is ideal for handling medium-sized components like exhaust systems, fuel tanks, and dashboards for automotive manufacturing. The NEO 30 improves safety and efficiency on the production floor by minimising operator fatigue and offering precise control.

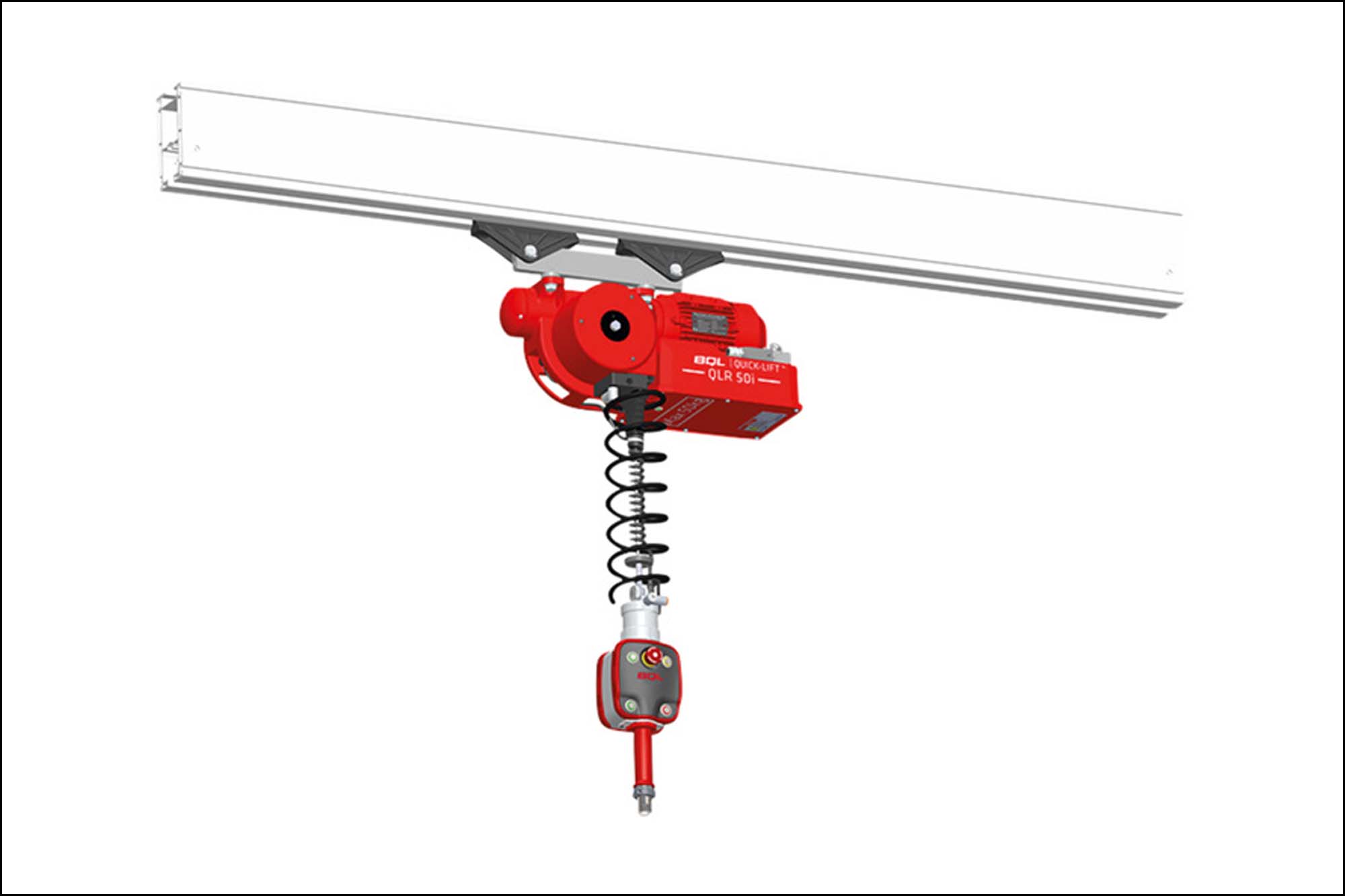

The quick lift arm of Binar Handling provides a robust solution for larger and heavier components. This arm can lift 300 kg, creating workability for moving components like doors, hoods, windshields, and body panels. The manipulators allow for precise placement of components for accurate alignment during assembly. This is because they are designed to mimic the natural movement of the human arm. This is particularly important when installing large parts, as it reduces the risk of damage and improves the quality of the assembly process.

Binar Handling’s Quick Lift Rail Systems also offer a flexible solution for moving parts across the production line. These systems allow operators to transport large or heavy components along a rail structure, reducing the physical strain of manual handling. In automotive manufacturing, this is particularly useful for handling the bulkier parts of a vehicle, such as engines and transmissions, between stations. The Quick Lift Rail System facilitates the smooth transport of large parts while improving the efficiency of the assembly process and reducing the risk of injury.

Binar Handling offers an extensive range of customisable end effects. These tools are designed to handle automotive components using pneumatic, magnetic, mechanical, or vacuum-actuated systems. For example, vacuum end effectors are perfect for handling fragile parts like windshields and side windows, ensuring safe, accurate installation. Magnetic end effectors are ideal for metallic parts such as axles, brake discs, and suspension components. End effectors of Binar ensure that automotive manufacturers can tailor their lifting systems to the specific needs of each production stage.

One of Binar’s standout products is the Ergo Glass End Effectors, designed for handling delicate glass components. These vacuumbased tools securely grip windshields, rear windows, and other glass parts, reducing the risk of damage during installation. In the automotive sector, where precision and care are essential for fitting glass components, the Ergo Glass End Effectors offer a safe and efficient solution that enhances the quality of the final assembly.

Safety is at the core of all Binar Handling products. Their ergonomic lifting systems have advanced control features that prevent human error and ensure that heavy loads are handled safely. The control handles include sensors that detect hand movements, while built-in auto-balance features ensure that parts remain stable during lifting. In addition, critical components are monitored for redundancy, reducing the risk of equipment failure.

Binar Handling’s ergonomic lifting systems are safe. The rotating swivel built into their lifting devices lets signal cables, airlines, and wire ropes remain tangle-free, reducing wear and extending the life of the equipment. This smooth operation minimises downtime and makes production continuous, helping automotive manufacturers meet tight production schedules.

What sets Binar Handling apart is the flexibility and adaptability of its products. Binar’s systems can be tailored to fit the specific needs of any automotive manufacturing process, with over 6,000 customisable end effectors and a wide range of modular lifting solutions. Whether lifting heavy chassis components or handling delicate electronics, Binar’s ergonomic solutions integrate seamlessly into existing workflows.

In conclusion, Binar Handling’s ergonomic lifting solutions provide automotive manufacturers with the tools they need to overcome the challenges of modern vehicle production. They reduce physical strain, improve precision and safety, help manufacturers streamline their operations, and improve overall productivity

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.