Airplane part manufacturing gets compact with carbon nanotube

By OEM Update Editorial February 8, 2020 1:48 pm IST

Aerospace-grade composites can now be produced with carbon nanotube film, eliminating the need for huge ovens or autoclaves.

A modern airplane’s fuselage is made from multiple sheets of different composite materials, like the many layers in a phyllo-dough pastry. Once these layers are stacked and moulded into the shape of a fuselage, the structures are wheeled into warehouse-sized ovens and autoclaves, where the layers fuse together to form a resilient, aerodynamic shell. Now, MIT engineers have developed a method to produce aerospace-grade composites without the enormous ovens and pressure vessels. The technique may help to speed up the manufacturing of airplanes and other large, high-performance composite structures, such as blades for wind turbines.

Out of the oven, into a blanket

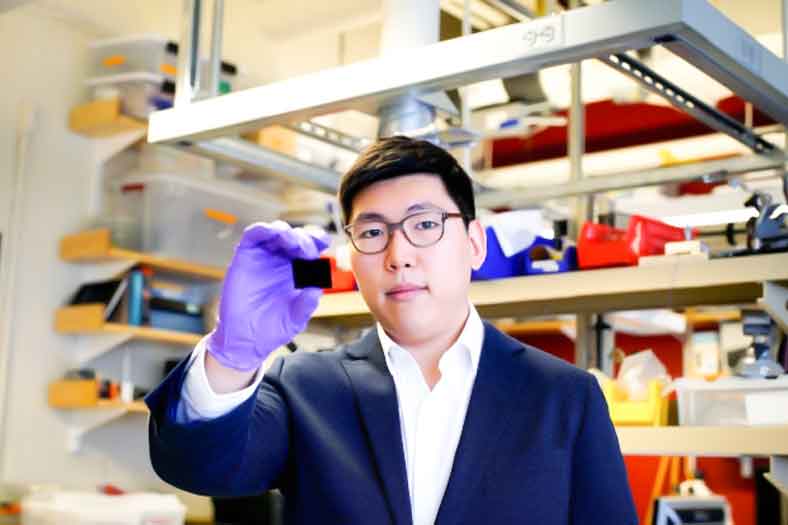

In 2015, Lee led the team, along with another member of Wardle’s lab, in creating a method to make aerospace-grade composites without requiring an oven to fuse the materials together. Instead of placing layers of material inside an oven to cure, the researchers essentially wrapped them in an ultrathin film of carbon nanotubes (CNTs). When they applied an electric current to the film, the CNTs, like a nanoscale electric blanket, quickly generated heat, causing the materials within to cure and fuse together. With this out-of-oven or OoO technique, the team was able to produce composites as strong as the materials made in conventional airplane manufacturing ovens, using only 1 percent of the energy.

The researchers next looked for ways to make high-performance composites without the use of large, high-pressure autoclaves. “There’s microscopic surface roughness on each ply of a material, and when you put two plies together, air gets trapped between the rough areas, which is the primary source of voids and weakness in a composite,” Wardle says. “An autoclave can push those voids to the edges and get rid of them.”

Straw pressure

Part of Wardle’s work focuses on developing nanoporous networks — ultrathin films made from aligned, microscopic material such as carbon nanotubes, that can be engineered with exceptional properties, including colour, strength, and electrical capacity. The researchers wondered whether these nanoporous films could be used in place of giant autoclaves to squeeze out voids between two material layers, as unlikely as that may seem.

The researchers tested their idea in the lab by growing films of vertically aligned carbon nanotubes using a technique they previously developed, and then laying the films between layers of materials that are typically used in the autoclave-based manufacturing of primary aircraft structures. They wrapped the layers in a second film of carbon nanotubes, which they applied an electric current to heat it up. They observed that as the materials heated and softened in response, they were pulled into the capillaries of the intermediate CNT film.

The resulting composite lacked voids, similar to aerospace-grade composites that are produced in an autoclave. The researchers subjected the composites to strength tests. “In these tests, we found that our out-of-autoclave composite was just as strong as the gold-standard autoclave process composite used for primary aerospace structures,” Wardle says. The team will next look for ways to scale up the pressure-generating CNT film.

For more detail, contact:

Jennifer Chu,MIT News Office

http://news.mit.edu/

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.