Vision and speech, Beckhoff’s technology innovation goes human

By OEM Update Editorial November 11, 2019 6:01 pm IST

In the Automation Expo trade show, which was exclusively focusing on automation domain, Beckhoff have increased their presence. “With displaying all technological innovations, Beckhoff’s product for this year’s expo was ‘Technological innovation in PC based automation,” says Ajey Phatak, Head-Marketing, Beckhoff Automation Pvt. Ltd.

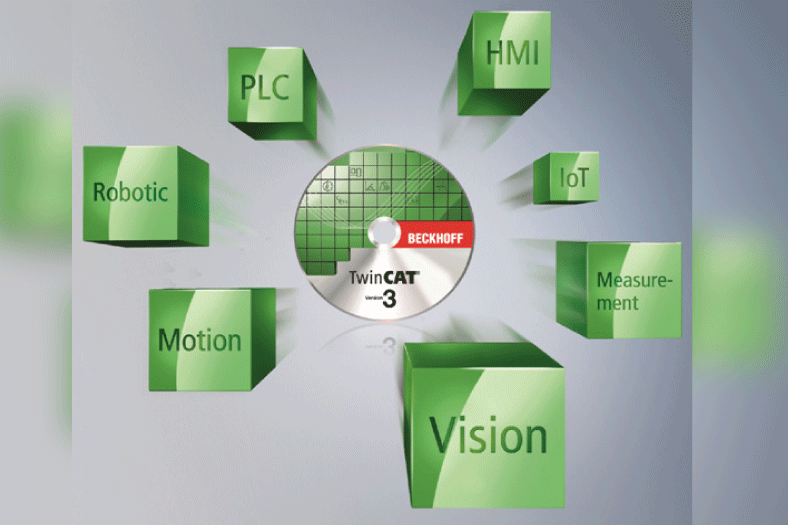

TwinCAT Vision – Machine vision easily integrated into automation technology

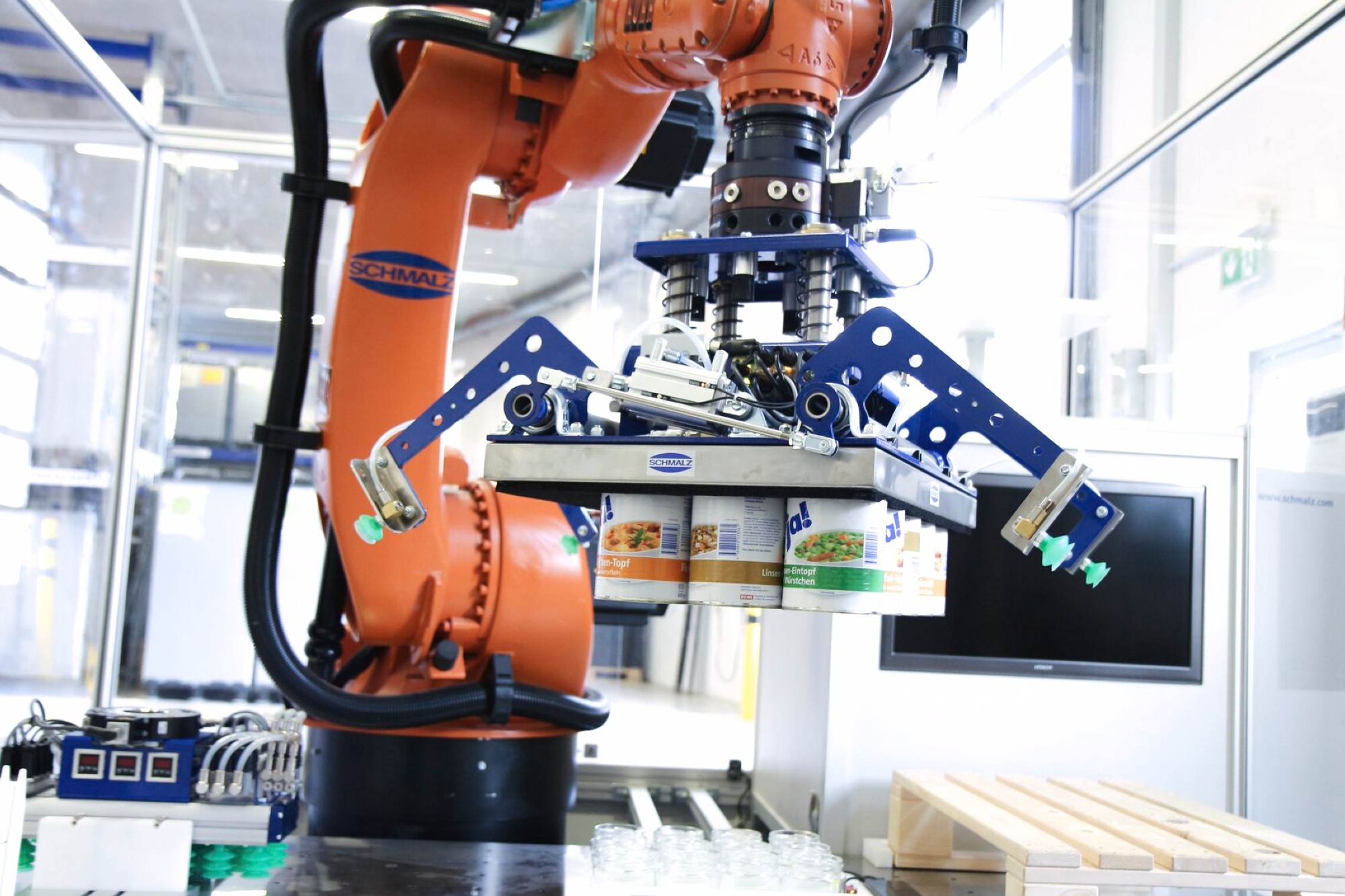

The latest one is TwinCAT vision automation where we can integrate the image processing software in our software itself. There is no need to buy separate software; you can connect any GIGe enabled or protocol enabled camera or any number of cameras and you can capture the image through PLC command to do the end of the line testing or visual programming for quality control, acceptance, rejections, or measurements etc. Accordingly, being a PC based system, it is very fast.

In automation applications, image processing has traditionally been handled separately and was often outsourced to external system integrators. Meanwhile, PLC programmers have branched out into numerous disciplines, including motion control, safety technology, measurement technology and robotics. It is possible today to combine all of those functions in a single control system on one computer. However, image processing has typically remained in a black box on a separate high-performance computer, with specific configuration tools and programming languages, or it is implemented directly in specially configured smart cameras. The downside to using a separate computer is that even the smallest changes require input from a specialist instead of the PLC programmer, resulting in avoidable costs. In cases where a third-party system integrator is involved, it also means that the expertiseremains external. In addition, the communication between image processing and the control system has to be regulated, which is a error-prone process. As a result, an exact timing in image processing could not be ensured. External processes, such as the operating system, can affect the processing time and the transmission time, so the results may not reach the controller in the required time span.

The new TwinCAT Vision software combines both worlds into one integrated system. The configuration, especially of the cameras, is carried out in the same tool as the configuration of fieldbuses and motion axes. For programming, the familiar PLC programming languages can be used. In this way, substantial engineering cost savings can be achieved, since there is no need to learn special programming languages, and no special configuration tool is required. The challenges of communication between image processing and control are not only eliminated, but image processing and control components can directly communicate with each other, opening up entirely new application possibilities. Everything is integrated into one tool and one runtime environment – this is the core innovation offered by TwinCAT Vision.

Architecture

TwinCAT SpeechTwinCAT enables automation systems to operate as efficiently and smoothly as the human body: an Industrial PC with a TwinCAT runtime provides the “intellectual capacity”, TwinCAT Motion Control ensures precise, dynamic movements, and I/O interfaces connect to the most varied sensors and bus systems to supply information. More recently, visual abilities have been added with TwinCAT Vision as a fully integrated component. With the new TwinCAT Speech software module, listening and speaking capabilities now complete the analogy with the capabilities of humans.

TwinCAT Speech allows multilingual input and output of queries or information in line with industry standards. This enables interaction with the automation system to be carried out much more efficiently and conveniently. The technology can be applied across numerous industries in a wide range of applications from machine design to building automation. When working on a machine component, for instance, operation and maintenance personnel can simply inquire about the impact of changed settings on the current control or simulation application without having to use a conventional operator interface. In addition, appropriate alarm messages can be given out acoustically when critical system values are reached.

Speech input is available as an offline function and is implemented on the basis of built-in Windows operating system functionalities. In other words, it is accomplished without requiring an Internet or cloud connection. Speech output from TwinCAT Speech is available both as an offline function and an online function. In the case of offline, support is provided by the appropriate Windows functionalities and in online cases via Polly, the text-to-speech service from Amazon. The realistic sounding speech output for these applications is synthesised with the aid of deep learning technologies. Multiple voices can be supported in addition to the caching of audio files generated online.

For more details,

E-mail: info@beckhoff.co.in

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.