Technologies should be democratised and made accessible

By OEM Update Editorial June 9, 2021 12:31 pm IST

We advocate creating a scalable architecture and adoption for futuristic technologies.

In an interview with OEM Update, Amitabh Chaturvedi, Director, InnovaPoint Infotech Pvt. Ltd., emphasises the importance of having a roadmap and planning to embark on the Industry 4.0 journey.

Based on your experience what do you think is the level of Industry 4.0 adoption in India?

We have been engaging with the auto OEM and auto component industry for last 4 years now and we witnessed that the awareness of Industry 4.0 is reasonably good; however, the depth of understanding varies considerably from OEMs to Tier-2 suppliers.

We have seen a considerable shift in the conversation, in the initial days’ discussions would revolve around production monitoring, OEE improvement etc. whereas now we are getting enquires around the traceability solution, predictive maintenance, tool cost optimisation which clearly shows that there is greater awareness and maturity.

While the awareness levels are good and there is an intent to embark on the Industry 4.0 journey, we have noticed that there is lack of planning and a proper roadmap. For example, some organisations have tried to achieve artificial intelligence-based benefits without having proper architecture and complete/good quality data. We always advocate companies to articulate their problem statements and objectives clearly and build a roadmap which can be broken down and adopt technologies that are scalable and futuristic.

We are optimistic and also see COVID being a catalyst in faster adoption of Industry 4.0.

You just mentioned about improving maturity in the industry, would you elaborate and give us some examples?

Let me give two examples; one on traceability and another from tooling.

The requirement was to capture the manufacturing process parameters right from casting, to heat treatment, to machining, to final testing for each individual engine part. The availability of this data from manufacturing till the end user would help in product quality monitoring and improvement.

The second example is from an organisation which is utilising the spindle load of the CNC machine to evaluate the tool condition and its remaining useful life. This would help not only in reducing the tooling cost but also improving the quality.

What advice do you have for the businesses planning to implement Industry 4.0 or have already embarked upon this journey?

What are the challenges for the SME and MSME sector in adopting factory automation and digitisation for efficient processes?MSME sector plays significant role in our economy. Our experience with SME and MSME sector indicates that these sectors are progressing well, however, still many challenges remain. In our opinion, top three hurdles that they need to overcome are

- To most MSMEs the Industry 4.0 initiatives may be intimidating. Therefore, it is important that MSMEs should be very clear of their objectives and break down the journey into smaller steps and lay the foundation on which they can keep building. Validating your plans by running initial pilots could be a good approach.

- MSME, find it challenging because of unsurety of ROI which can be addressed by innovative pricing models. We, at sfHawk, believe that technology should be democratised and available to even the smallest of the SME/MSME.

- Bringing about a cultural change in the organisation as SME/MSMEs undertake Industry 4.0 journey is a challenge and adequate efforts has to be made in training and involving employees on the shopfloor so that they own up to the initiative.

Question 5: What are the latest technologies offered that can reduce the downtime and bring precision to the Indian Manufacturing?

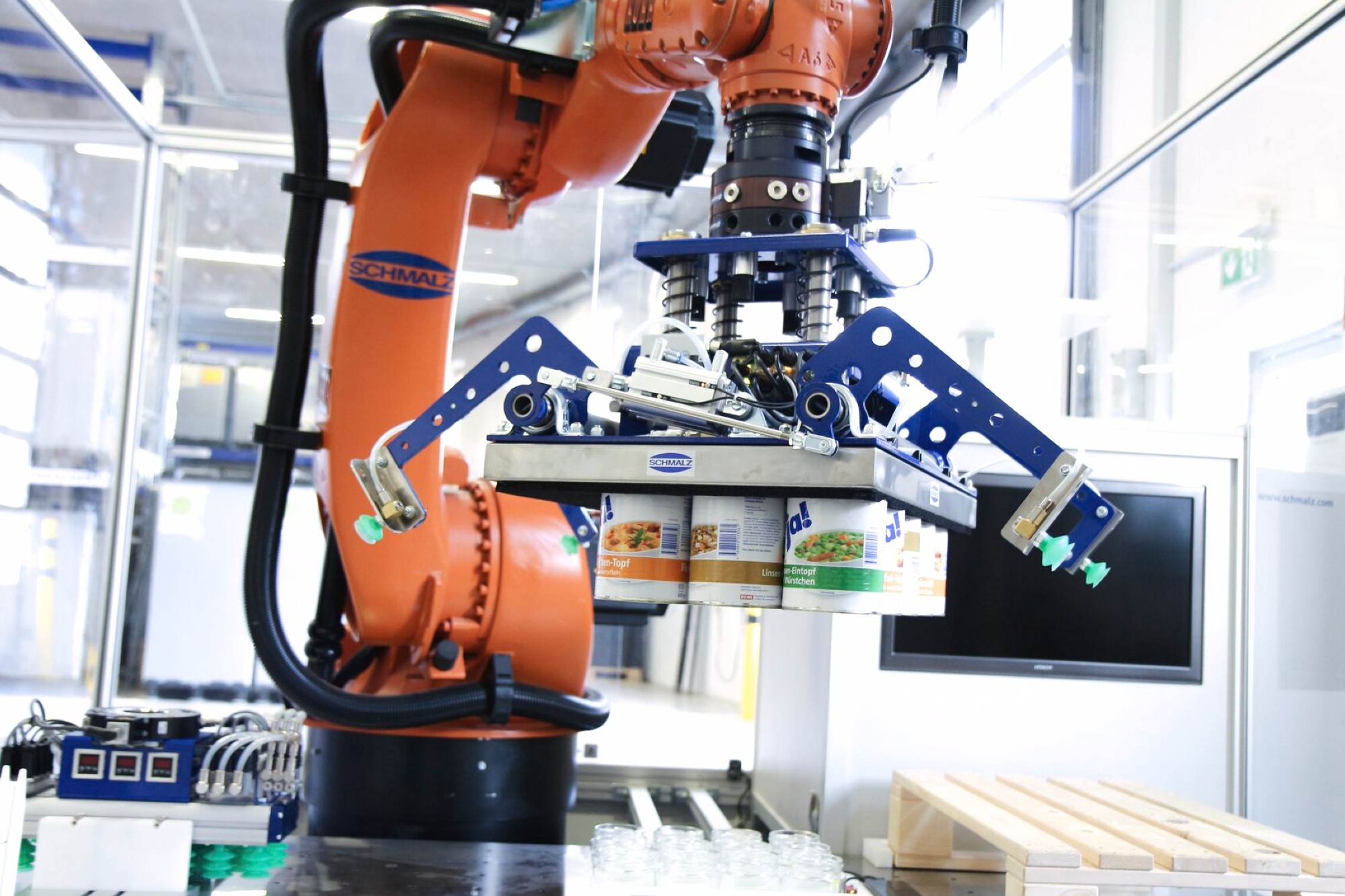

With immense data that is available now in factories and with the help of software tools, there are enormous opportunities available to reduce downtime and improve quality. Technologies like AI, AR, Robotics, 3D printing is already available and organizations are yet to harness these completely. While newer technologies will evolve, we think that is a huge potential available and companies should focus on maximizing. The benefits could be realized by –

- Building an architecture where machine to machine talking is enabled for better process controls. Let me share one example from assembly line, where all the nut runners, oil fillers and such equipment automatically update their configurations based on the vehicle model they have in front of them.

- Leveraging the Artificial intelligence (AI)for faster and accurate data driven decision making, for example, predictive maintenance and tool life monitoring.

- Capturing the process parameters against the individual components at various stages right from the source and monitoring it till end customer.

Question 6: What are the safety protocols you follow in terms of securing the safety of your solutions from malware or an external interference?

Thanks for asking this question. This is very important aspect of Industry 4.0 initiatives. We partnered with a cyber security agency right from the beginning of the sfHawk designing. We have several system level security aspects such as authorized component communication, application-level security like penetration testing, taken care of in the development phase. Also, we follow many execution time security protocols like secured and dedicated wireless network for sfHawk operations, OS hardening etc. Based client’s preference and their existing infrastructure, we offer both on-premise as well on cloud solution.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.