Robotics and automation driving growth and reshaping the future

By OEM Update Editorial March 12, 2024 1:58 pm IST

Subrata Karmakar, President of robotics and discrete Automation at ABB India, discusses how robotics and automation impact workplace safety and efficiency and enhance productivity, thus redefining job roles for a more fulfilling work environment.

In what ways collaboration between ABB Robotics and Simpliforge Creations utilises advanced 3D printing technologies to enhance the Indian construction sector?

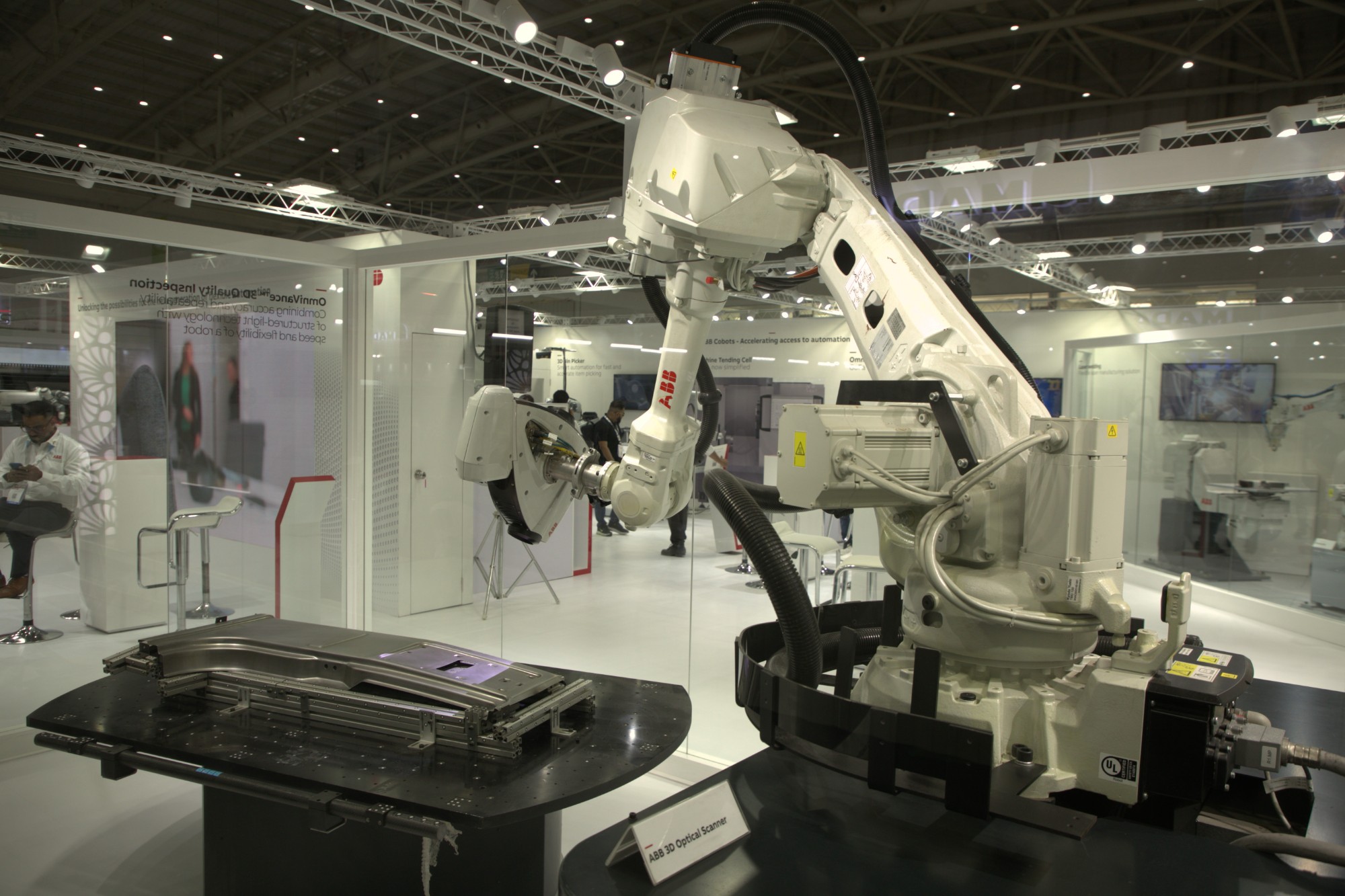

The collaboration between ABB Robotics and Simpliforge aims to empower construction firms to accelerate building construction more efficiently, sustainably, and securely. The innovative 3D printing technologies and solutions can transform construction practices across various industrial, defence, commercial, and residential sectors. This is particularly valuable in disaster areas, where swift rehabilitation and infrastructure restoration are crucial. ABB’s IRB6700 robots, integrated with Simpliforge’s proprietary software, are equipped with advanced payload management. They are designed to operate effectively in wet and rugged construction environments, making them the best choice for 3D-printed construction. The system ensures unprecedented accuracy, precision, and reproducibility, reducing reworking and quality control costs. This comprehensive solution complements traditional construction methods, offering a comprehensive solution for the industry.

How the evolving trends in robotics are contributing to the development of a smart and sustainable future?

The development of a smart and sustainable future is shaped by the changing trends in robotics, with flexibility being a key factor achieved through intelligent automation. Our robotics and automation solutions are key in offering customers the necessary flexibility, agility, and adaptability for their operations. While the historical focus of automation has been on enhancing productivity and quality, the current emphasis is on the strategic importance of flexibility and user-friendly interfaces. In the current landscape, entities that fail to adapt in areas such as production, logistics, or distribution face survival risks. Envisioning a future where robots are as ubiquitous in workplaces as laptops or smartphones, our vision involves a collaborative partnership between robots and humans. This collaboration aims to enhance the gratification and productivity of work, creating safer and healthier work environments and ultimately contributing to a more sustainable future.

How does the rise of robotics and automation influence robot density to drive growth?

In 2021, the sale of industrial robots in India reached a high of 4,945 units installed, indicating a 54% surge compared to the previous year (3,215 units in 2020). This achievement positions India as the tenth-ranked country globally regarding annual installations, as reported by the International Federation of Robotics (IFR). The adoption of robotics and automation has significantly improved workplace safety, efficiency, and overall productivity. For instance, according to the International Trade Administration, there was a 0.8 percent increase in productivity for every 1% rise in robot density. Industries just starting to implement robots witnessed the most substantial productivity growth, driving advancements across various industries.

In what ways is the future workplace expected to evolve with the cobot integration?

The introduction of collaborative robots is poised to transform the future workplace in multiple ways, particularly through their digital features that enable easy configuration and operation, even for individuals without prior knowledge or experience of using robots. This reduces installation costs and minimises the overall space requirements, making it particularly advantageous for space-constrained environments.

The most substantial growth in this sector is currently observed in general industry and small to medium-sized enterprises. This trend is propelled by the availability of smaller, more cost-effective, and user-friendly robots, as proved by ABB’s Cobot family. These robots are instrumental in automating repetitive, dirty, or hazardous tasks, eliminating the need for human involvement in such risky activities and allowing them to focus on more fulfilling and thoughtful work.

Please talk about applications of AI in data analytics and robotics in the manufacturing industry.

Artificial Intelligence (AI) improves the efficiency, reliability, productivity, and, particularly, the adaptability of production and logistics procedures. In this framework, autonomous mobile robots operate independently, manoeuvring materials, components, and completed products among intelligent, interconnected workstations. This advancement replaces traditional linear production setups with entirely flexible networks. The ultimate objective is to create data-driven enterprises where autonomous systems powered by AI independently adjust their actions according to production needs, leveraging the data they gather. This paves the path for the next generation of flexible manufacturing.

How are changing consumer behaviour and the emerging e-commerce industry impacting manufacturing industries?

The changing patterns of consumer behaviour, marked by a rise in online shopping and a strong preference for diverse product choices, shorter product lifespans, and personalised items, are prompting our clients to improve their flexibility. Our advanced robotics solutions go beyond traditional manufacturing. It contributes to increased efficiency and adaptability in rapidly expanding sectors like healthcare, logistics, food and beverage, construction, and retail, specifically focusing on the dynamic e-commerce domain. These shifts reflect the significant influence of changing consumer preferences and the burgeoning e-commerce sector on manufacturing industries, particularly within the context of robotics and automation.

In what ways is upskilling helping to train individuals to operate and maintain robots for an impending automated future?

An intensified focus on education and training is crucial, necessitating the retention of engineers and staff and, simultaneously, providing the necessary skills to program, operate, and maintain robots in the ever-changing landscape of automation. There is an increasing demand for comprehensive training programs in educational institutions, from schools to universities, to adequately prepare individuals for the complexities of managing robots in an automated future. We actively contribute to this initiative through 42 professional training centres worldwide, where customised training is offered with a specific emphasis on robot programming. Our dedication is evident as we annually involve 17,000 students in these training courses, playing a crucial role in readying individuals for the imminent challenges of an automated future.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.