New generation robot systems play a key role in Industry 4.0.

By OEM Update Editorial June 12, 2018 11:39 am IST

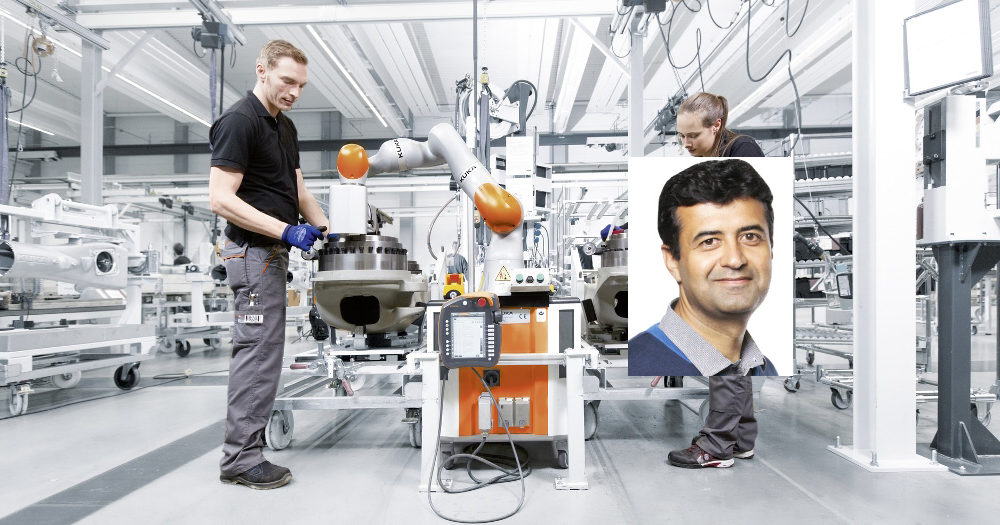

Pradeep Shoran,

AGM-Marketing, KUKA Robotics India Pvt Ltd

Based on the IIoT platform from KUKA, the VINCI Energies brands for ICT and industry – Axians and Actemium – will implement holistic Industry 4.0 solutions from design to system integration.

Future look for IIoT in manufacturing

Industry 4.0 or “the fourth industrial revolution” is the current mega-topic in industry. There are still no comprehensive standards for it; nor there is a uniform perspective. Buzzwords such as “smart factory”, “smart production” or the “Internet of Things” only describe what the factory of the future could look like. “What people do agree about is that Industry 4.0 is an important, and possibly decisive, field of future activity. After all, companies not just in Germany but also further afield are expecting the intelligent networking of all production-relevant components to deliver a quantum leap in productivity, flexibility and efficiency, thereby safeguarding competitive advantages, observes Pradeep Shoran, AGM-Marketing, KUKA Robotics India Pvt Ltd.

Augmented reality and products for the IIoT market

The KUKA subsidiary connyun is one of the first companies to introduce two standard products for the Industrial Internet of Things (IIoT) market. With the I4_suite, connyun promises standard products under the aspects “Integrated – Intelligence – Industrial – IoT”, which production operators can use quickly and offer them significant advantages regarding availability of machines and stations. Device Insight will application possibilities of augmented reality using smart glasses and tablets. The new service will connect technicians on site with remote specialists and combines system data from the IoT platform and local live recordings.

“Cloud in a box” as the first step towards the “smart factory”

It will already be possible to achieve the first quantum leap in productivity today, however, if the idea of global networking is initially implemented within a defined environment; it will be like a “cloud in a box”. This is realistic both for one or more factories and for an entire company or group of companies. If it proves possible to network the various productive systems with flexible interfaces and to expand them with IT technologies such as the Cloud or Big Data, this will represent the first step towards the smart factory. KUKA already offers all the necessary components for this today: integration of third-party software, modular control architecture for maximum scalability, support for internationally recognised standards, maximum interoperability thanks to mainstream IT, an extensive software library for developers as well as a shared database for the greatest flexibility.

Industries that will drive IIoT adoption

The possibilities are enormous in almost every Industry. One such example is mentioned below.

The automation specialist KUKA and VINCI Energies in Germany intend to collaborate in the development and implementation of digital services as well as applications for the IIoT. Both companies have committed to this goal in a memorandum of understanding.

The robot is the link between IT and production. Robot systems of the new generation are already playing a key role in Industry 4.0.

Connyun – Driving the ecosystem principle

The start-up based in Karlsruhe is a subsidiary of KUKA and offers technology that can connect machines and services through their Industry 4.0 cloud platform. The goal is to network machinery and components in production systems, enable them to communicate, and collect data that can be analysed. The linkup to the cloud facilitates process and product quality improvements. connyun relies on an open software architecture, making it extremely easy for customers to take the first step. In addition, end customers are offered a comprehensive eco-system, with partners and start-ups who can offer their software solutions (services) on the connyun platform to establish a rapidly growing solution portfolio.

With the cloud platform, connyun provides a technology with which the ecosystem partners can develop and offer their Industry 4.0 solutions. The ecosystem philosophy covers both KUKA’s own and partner solutions in order to be able to offer end customers extensive options for optimising their production and logistics processes.

In the recently concluded Hanover Messe, connyun presented the topics of Machine Connectivity, Big Data and Data Analysis, Industry 4.0 applications for mechanical engineers as well as manufacturing and software ecosystems.

Why robots are in the vanguard of the fourth industrial revolution

Irrespective of which standards will be established at the end of this process, one thing is already clear: the robot will play a key role in Industry 4.0. As the most flexible production element, it already collects data in production today and supplies the data to the IT system. It is the arm of IT in production, it provides the link. In future, the IT will process these data and return them to production via the robot so that production will be able to optimise itself successively on this basis. No other component in the production process is currently capable of accomplishing this supporting role as effectively as modern robot systems are. Back in the 1990s, KUKA recognised that interfaces based on mainstream IT technologies will be essential for responding to the needs of industry and enabling digital controllers of different systems to be networked with one another efficiently. The watchwords are open communication and simple integration – oriented towards the cloud and its potential services. This makes KUKA robots all-rounders for smart, networked products and solutions that will provide automation solutions with services and databases within the foreseeable future.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.