Investing in new technologies to prepare for Industry 5.0

By OEM Update Editorial June 9, 2021 2:27 pm IST

This article gives you a brief view about the automated technologies, robotics, and its benefits for the industrial uses.

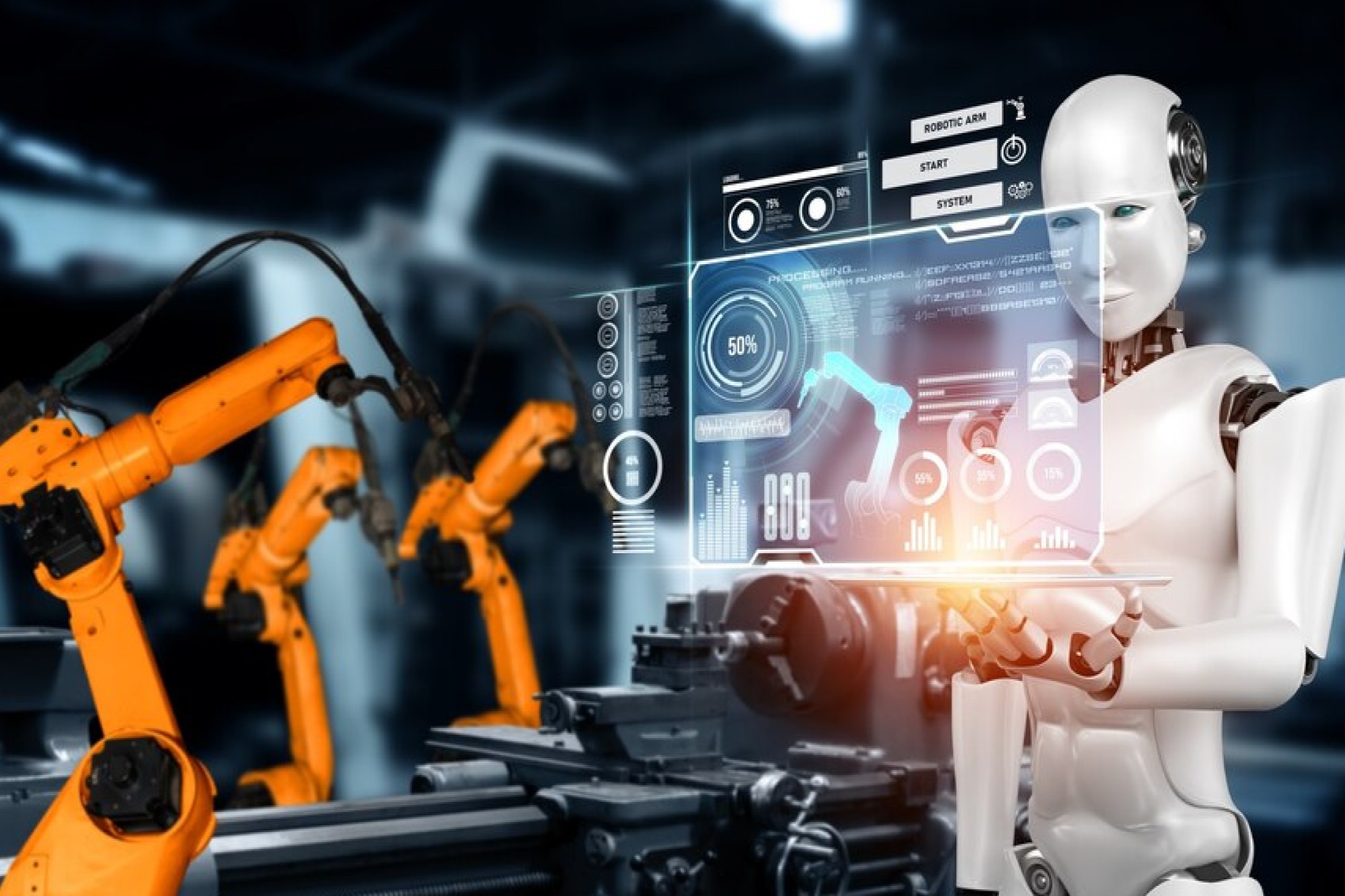

Industry 5.0 is not a phrase we use much internally at Inovance however, the concept behind it – improving the way that people work alongside machinery – is important and relevant. The message is a nice counterpoint to the Industry 4.0 messages about efficiency and automation. Increasingly, many seem to believe that automation will phase out humans altogether. This is not the case. Machines exist to improve the productivity of human workers, not to replace them. In that sense, I think Industry 5.0 is a good corrective.

My company, Inovance, is a manufacturer of the full range of industrial automation components, and we are investing heavily in the technologies that Industry 5.0 will depend on. Chief amongst these is safety.

Safety systems for automated machinery

Clearly, you can’t have people working alongside machinery if there’s a risk of injury. That’s why, historically, automation has been in fenced off sections of the factory. This is now changing, which is what is driving the Industry 5.0 conversation.

Here at Inovance, we see safety as a top priority. For example, recently Inovance’s Indian sales teams have been making a push to promote our SV660N servo drives which include STO (safe torque off). Why is STO important? Because it guarantees safe machine stop when the emergency stop is triggered – preventing huge numbers of injuries. We’ve made a particular effort to bring SV660N to India where we’ve seen strong interest due to our high safety standards and cost-effective solution.

More widely, Inovance is fast tracking functional safety features in all our new product development in order to ensure that our products can be used in the latest Industry 5.0 applications.

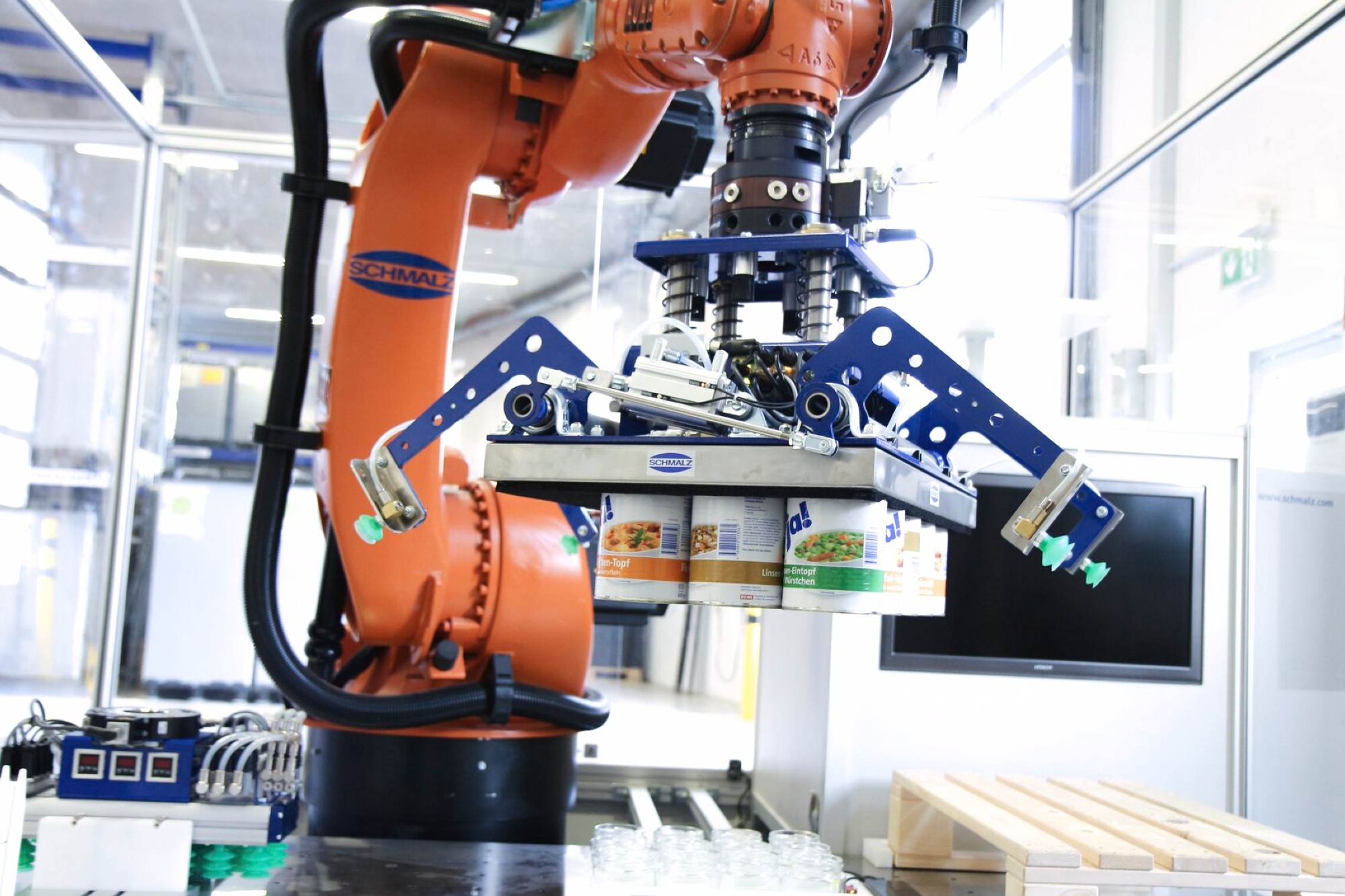

Robot vision

Connectivity is keyFor Industry 5.0 to work properly, connectivity is key. And that’s why we have worked hard to ensure our key products work with critical Ethernet-based fieldbus systems such as EtherCAT. Our total motion solution, consisting of IPCs, motion controllers, and servo drives & motors, has EtherCAT capabilities across the board. There are many benefits to EtherCAT, but it essentially comes back to the need to provide faster communications: EtherCAT provides some of the highest communication speeds and efficiency available on the market. Additionally, EtherCAT can function as a safety bus so that, if a stop command is given, there are checking systems that confirm the command has arrived at the slave.

If Industry 5.0 is to achieve its full potential, then all kit, no matter who made it, must be interoperable. Organisations such as the OPC Foundation – the world’s leading community for open industrial automation interoperability standards – are key to this goal.

At Inovance, we are proud to have recently been welcomed as OPC’s 800th member. We see this as critical to our ability to help manufacturers develop advanced solutions. For India more widely, I think companies have embraced Industry 4.0, which has led to significant improvements in Indian manufacturing. With that in mind, I feel that Indian enterprises are now more than ready to accept Industry 5.0.

A word on MSMEs

One side note is to consider micro, small, and medium manufacturing enterprises. India has many such businesses and there is a tendency for them to assume that the latest factory automation technology is expensive and therefore not for them. This is incorrect. They should look carefully at automation technology and they will find that sophisticated solutions are not expensive, and can radically improve their competitiveness. What small businesses need is to find a full-spectrum automation partner who can help them in their journey to Industry 5.0.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.