IIoT to drive new revenue streams

By OEM Update Editorial June 11, 2018 6:15 pm IST

Nishit Behera,

Executive Director – Business Development & Strategy,RSB Transmissions (I) Ltd

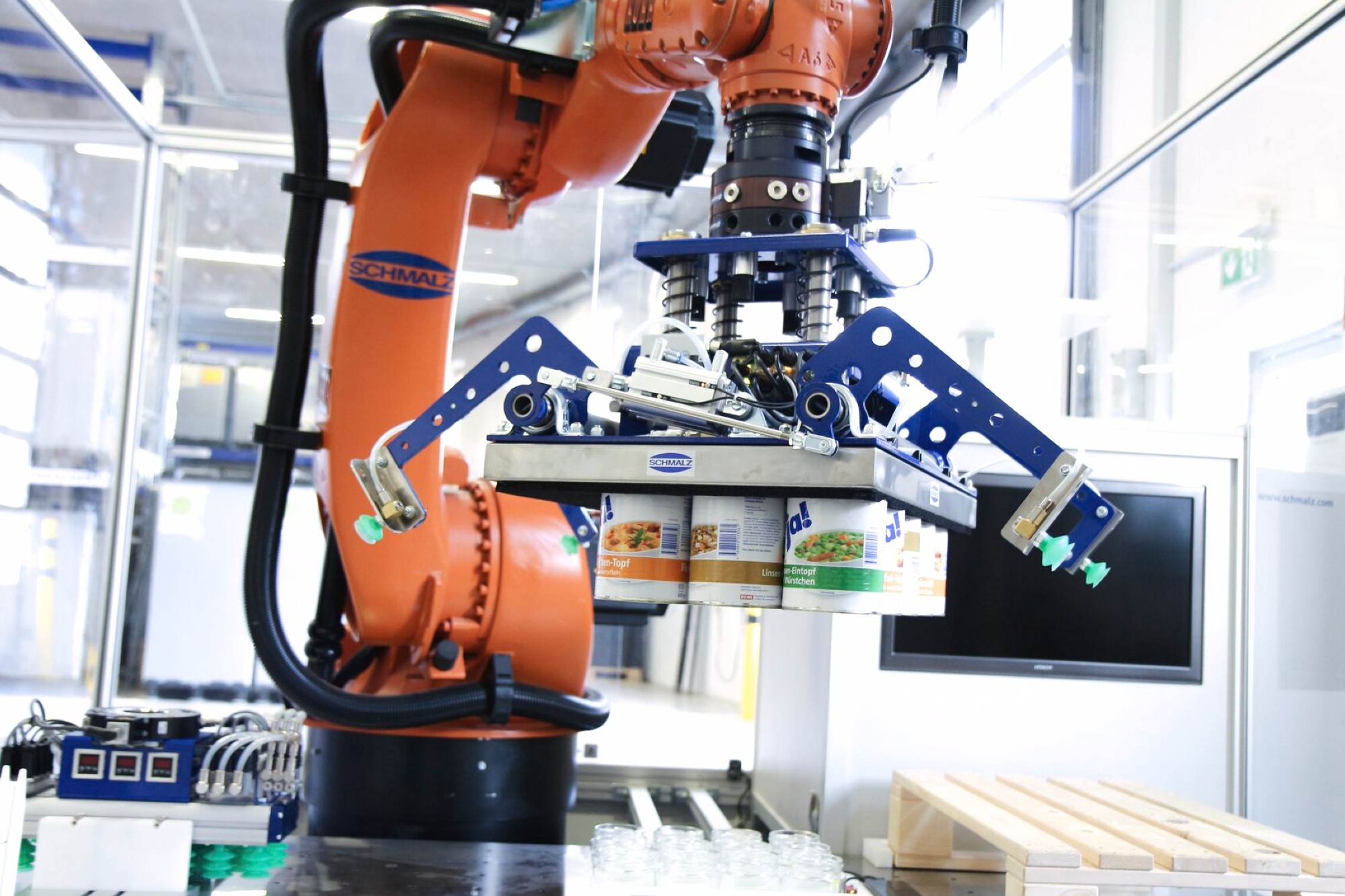

IIoT will entail extra investments to keep pace with technology.

Future look for IIoT in manufacturing

With rapid march of IIoT, a backbone of e-factory set-up, it has become a dire need for manufacturers to stay closely connected in order to amalgamate different technologies like Machine Learning, Big and Sensor Data, Machine-to-Machine Communication and Automation to boost operational efficiency, increase productivity and reduce complexity of process, to gain edge in competitive market and open new revenue streams, observes Nishit Behera, Executive Director – Business Development & Strategy, RSB Transmissions (I) Ltd.

Cognitive systems and real-time analysis give valuable insights to improve reliability and quality of output while supporting manufacturers to introduce value-added services to customers. “IIoT concepts create automated and seamless transactions in their productive process by deploying sensors, initiate communication with multiple devices and implant analytics solution to derive actionable insights, he adds.

“There are challenges in IIoT adoption. Maintaining and updating complex systems from in-house and remote locations have exposure to potential cyber attacks over the connected net works, adhering to standards of local net works for bandwidth and latency, data integrity and security, IP protection, etc.” explains Behera.

Cyber attacks against critical infrastructure have much higher stakes than typical IT net works. Implementing IIoT technology means introducing new security tools to the network

The network could go to potentially thousands of connected sensors and devices. It’s hard enough to manage visibility for a single factory floor—but the IIoT will add additional challenges as we scale it globally. One being availability of competent manpower to manage the system. Behera adds, “IIoT will entail extra investments to keep pace with technology.”

Industries that will drive IIoT adoption in 2018Traditional industries, like manufacturing, that have been struggling to showcase differentiated products, will now benefit from IIoT to drive new revenue streams to give significant yield improvements for their customers.

Industry where assets are being digitised, will make a leap towards connecting or instrumenting green field projects and is well positioned to leverage the value of digital intelligence feels Behera. He adds, “Usually, the goal of these initiatives is to have deep business impact. This can be delivered by tapping into unknown or unrealised efficiencies and optimisations. Often surprising insights are uncovered only through analytics and machine learning. Industries with often limited access to bandwidth, such as oil and gas, mining, fleet and other verticals, truly benefit from the digital intelligence. Added to this, they will benefit from real-time decisions, as well as insights from voluminous streaming sensor data.”

The retail, healthcare, and industrial/supply chain industries are likely see the greatest growth. It is no surprise that retail is jumping aboard, hoping to harness the power of the IoT to connect with customers, grow their brands, and improve the customer journey in deeply personal ways. Healthcare and supply will be using the technology to connect with patients via wearable devices, and track products from factory to floor.

In auto segment, auto giants connect the cars with embedded connections through in-built antenna and chip. Added to this are tethered connections to allow drivers to connect to their cars via their smart phones. Mobile app integration is common through Google Maps and other navigation tools.

Embedded system through IIoT will enable auto manufacturers to monitor health parameters of their models, specific fuel consumption, break downs, quality issues, mileage and other competition parameters digitally and take corrective actions proactively before the bell rings from the customers.

RSB’s preparedness in the area of IIoT

“Our shops floors across 11 plants in India have latest art of machines and facilities, robotic engineering and components produced to micron precision with digital intervention and zero defects,” informs Behera. He adds, “Our company has won coveted world-famous deming prize for business excellence, a highest quality mandate and as such, perpetually have a built-in system flexible enough to take on any changes.

The company have a rugged in-house IT, manned by qualified and experienced professionals to take on the change. Besides, we are connected digitally across our plants in India through our internal net work with data integrity and security.

“We have the necessary platform and infrastructure for digital transition and e-factory administration. We already have plans and studying different products and manufacturing facilities to take on new digital era and move over is expected to be smooth as will be mandated by OEMs in due course and from time to time,” he adds.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.