IIoT poised to take industry to next level

By OEM Update Editorial June 12, 2018 12:43 pm IST

Ninad Deshpande,

Head- Marketing, B&R Industrial Automation

In all aspects, B&R is a partner for a successful IIoT implementation providing solutions for machine as well as factory automation.

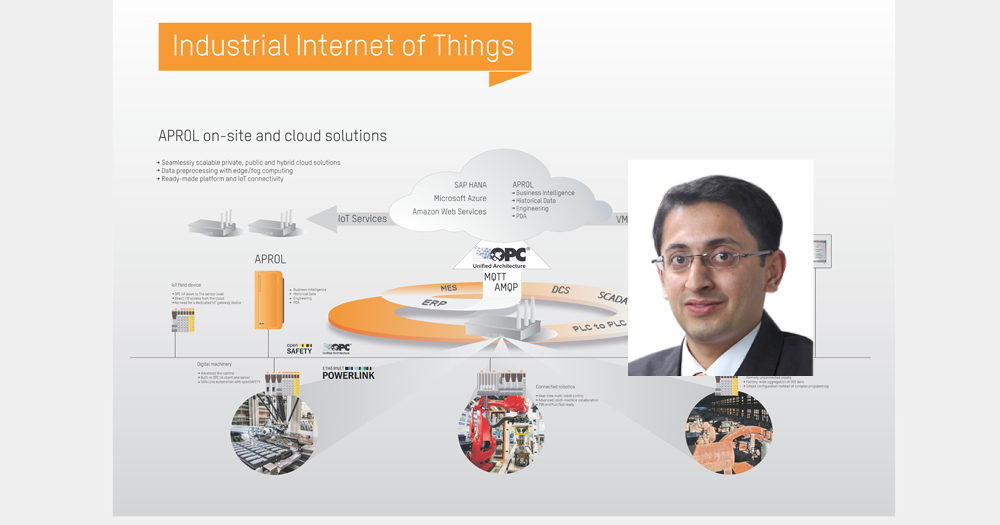

Imagine factory heads using their smartphones or tablets, walking on the shop floor connecting to any machine on their way to check the production count, idle time, efficiency, energy consumption, status of predictive maintenance and the overall equipment effectiveness. Management executives accessing shop floor data from anywhere across the world and maintenance people diagnosing problems in machines and factories from their homes. Robots working hand-in-hand with humans without cages and barricades. Design engineers being able to understand working of machine mechanics even without machining components or availability of electronics and predict machine behaviour at their customer sites enabling them to provide best in class after sales service. What if shop floor was connected and machines from different vendors could talk with each other over a common communication protocol just as we humans can communicate with anyone using a common language such as English? These are few of the aspects, which Industrial IoT brings to the table for manufacturing setups and these technologies would eventually make factories of the future. The economic value is immense and early adopters are already reaping the benefits of this revolution. IIoT guarantees not only connectivity but also secure connectivity to machines. Using open source vendor independent networking on shop floors such as OPC UA enables machines from different vendors communicate with each other without the need of a gateway or a protocol converter. This makes horizontal communication a reality, which today is unheard of especially with various amounts of Ethernet networks existent. OPC UA is open source as well as provides all necessary security mechanism, which help connecting to upper layers such as IT, MES and ERP systems. Major Cloud platforms have already adopted OPC UA as a standard for networking.

In addition, other queuing protocols such as MQTT and AMQP too are widely used in shop floors and cloud platforms for vertical communication. Thus, with OPC UA, MQTT and AMQP factories can fulfil their unfulfilled desires of horizontal as well as vertical connectivity.

IIoT also facilitates the possibility to virtualise any machine and enable machine builders and factory operators to predict failures early and reduce unplanned downtimes using digital twin. In addition, robots and humans will be seen sharing the workspace without the need of cages thanks to human robot collaboration. IIoT is making all of this a reality with it trusting openness helping bring multiple vendors on a common platform.

Accessing machine and factory data from any corner of the world on a device connected to the Internet was a distant wish of many. Today, with IIoT it is not only made easy but also affordable to all. This data would be converted to valuable information by various programs and will be used to display trends and graphs for providing complete analysis of any machine or shop floor. Based on this information factory operators and machine builders would be in a better position to understand machine working, operation, detect failures or enhance machine and factory performance. IIoT will help gather data, enhance performance as well as optimise various operation parameters online. Factories of the future will be nothing like what we are seeing today and owing to the fast-changing technology it is expected to further enhance shop floors in a relatively shorter time.

Early adoptersThere is no industry, which will be happy to miss the train and perceived benefits being offered by IIoT. Thus, all industries are striving hard to become ready for the future and are working hard in this direction. The question is: who would like to stay and operate the way they are and miss the immense opportunities lying ahead on the path to IIoT? However, a few industries are showing notable moves in this direction of IIoT. Pharma 4.0, Packaging 4.0, Textile 4.0 autonomous cars and off-highway equipment are some of the activities evident in the market today. Some industries are also getting enormous push from various governments. Even Indian government is fuelling growth and technology adoption for in various industries SMEs to adopt technologies and move in the director of IIoT. It does not mean that other industries are not showing any activity and are in no way lagging the market. Everyone is eagerly working towards becoming more and more competitive using advanced technologies. IIoT has been the talk of the town for over a couple of years and is expected 2018 to be a year of action for many industries. The phase of evaluation and technology understanding have gone by and necessary actions to be lined up for the coming years. Organisations will strategise and work at effectively executing the action plan. However small steps might be taken by organisations from various industries will be a positive move in the direction of becoming IIoT ready and adopt certain technologies making their machines and plants more efficient and smart.

B&R: A partner for a successful IIoT implementation

What today is paraded under the banner of Industry 4.0 has been common practice at B&R’s own production facilities for nearly a decade. The smart factory in B&R headquarters at Eggelsberg has been fully networked since 2006 and is being upgraded all the time. The company has optimised production of its industrial PCs using an online configuration tool the customers can assemble their PCs to their exact specifications. After verifying the feasibility of the configuration, the ERP system automatically generates a bill of materials with a unique serial number. Mathematically B&R’s customers can have more than 250 billion different hardware configurations to choose from. They have a single, homogeneous network that incorporates every machine and every building automation component as well as the ERP system. Since inception, B&R has been trusting open source technologies across the spectrum enabling machine to operate with real time deterministic network using Ethernet POWERLINK, with OPC UA, MQTT and AMQP the company provides customers with horizontal and vertical networking from sensors to ERP, MES or even Cloud. openSAFETY a TÜV certified SIL 3 protocol helps in providing necessary safety levels over any fieldbus as it is the only protocol, which is fieldbus independent. With Orange Box, B&R helps brownfield installation become smart and IIoT ready. Orange Box from B&R helps brownfield sites achieve greenfield benefits without changing the existing system and with minimum investment. Automation Studio, the single tool for programming all B&R hardware has an in-built simulation environment helping machine builders with virtualisation and digital twin. In addition, Automation Studio links up with Matlab, MapleSim and simulation tools providing virtualisation of assets, mechanics and shop floors. With the next generation industrial transport technology such as SuperTark and ACOPOStrak, B&R is redefining the future of transport technology enabling machine builders achieve higher OEE, smaller machine footprint, batch size one production, mass customisation, shorter time to market and can further accelerate their return on investment. These technologies enable adaptive manufacturing and are a generation leap ahead of market.

B&R also provides a complete integrated with APROL as a factory automation solution. Also able to view parameters such as overall equipment effectiveness (OEE) at any time and can even compare between production lines, shifts or workdays. This is couple with energy and condition monitoring. With secure remote maintenance, B&R provides secure and easier diagnostics at machine builder’s fingertips reducing their downtimes, drastically improving maintenance and enhancing after sales service. In all aspects, B&R is a partner for a successful IIoT implementation providing solutions for machine as well as factory automation.

Authored by:

Ninad Deshpande,

Head- Marketing,

B&R Industrial Automation

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.