i-BELT connects manufacturing data with production processes

By OEM Update Editorial September 18, 2023 5:25 pm IST

In addition to an extensive range of automation solutions, including smart sensors, robots, vision systems, drives, etc., the inclusion of i-BELT further enhances Omron’s comprehensive lineup of end-to-end solutions, providing valuable data-based services and consultation from a holistic perspective.

Enabling a streamlined digital evolution, OMRON facilitates gathering data at all operational and process levels. Through i-BELT Data Services, it empowers customers to harness the potential of data for their benefit. This service connects manufacturing data with production and management issues, transforming raw data into valuable insights using OMRON’s proficiency. The aim is to attain enhanced predictive and preventive maintenance standards, addressing various production challenges such as unforeseen downtime, subpar quality, reliability concerns, rising maintenance expenses, and more. The ultimate goal is to elevate overall equipment effectiveness and facilitate well-informed decision-making.

Sameer Gandhi, MD, OMRON Automation, India, said, “One of the most effective traits of i-BELT is the co-creation synergy of OMRON technology and customer processes. The idea is to empower our customers for the best and most effective data harnessing and utilization. The data collected and visualized is fed back to the customer’s production line to help them attain flexible, people and environment-friendly production that is quickly adaptable to changes through Co-creation, formulation of challenges based on data and advancement of innovation in phases. The cycle continues, thus resulting in a truly sustainable value creation over a period.”

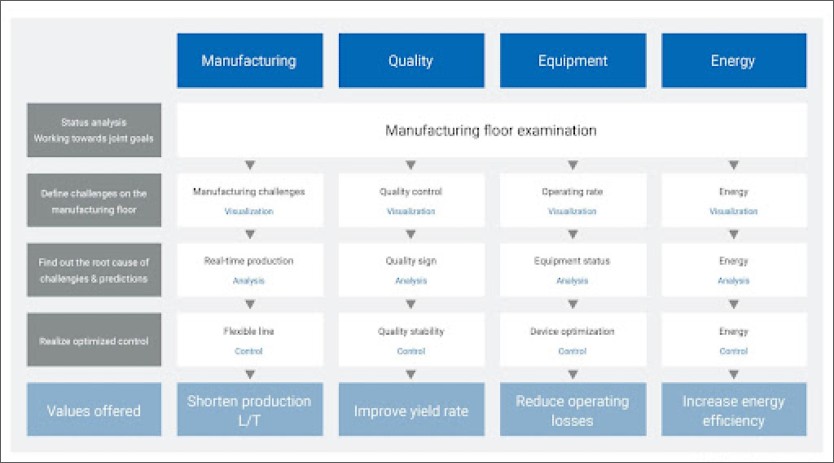

OMRON’s plant examination service focuses on four domains -manufacturing, quality, equipment, and energy. The i-BELT team extracts issues through visualization and analysis and provides services, such as improvement assistance and automation, suited to different phases and needs. The technology also focuses on energy efficiency by monitoring power consumption and providing insights into optimizing overall plant system configuration. Fine-tuning these parameters helps minimize energy waste and improves overall system efficiency. This reduces energy consumption, lower operational costs, and a smaller environmental footprint. It significantly impacts the attainment of carbon neutrality goals- one of the prime imperatives for sustainability for manufacturing businesses.While i-BELT holds promise for various manufacturing sectors. i-BELT includes an application that exhibits the effective integration of historical and real-time data from palletizers into a dashboard. This integration offers improved control and operational visibility. Alongside its emphasis on data-driven services, OMRON continues to bolster its traditional product lineup.

Recent additions to the company’s offerings encompass the advanced NX502 Controller, which incorporates enhanced capabilities in information, motion, and safety control. This enables the achievement of elevated levels of production, quality, and energy efficiency. Additionally, the introduction of the TM-20 collaborative robot for handling heavy payloads marks a noteworthy step in OMRON’s efforts to cater to the Indian market.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.